Method of designing vibration exciter for constructive machinery

A technology of construction machinery and design methods, applied in chemical instruments and methods, fluids using vibration, clay preparation devices, etc., can solve problems such as reducing bearing life and reliability, complex overall structure of the machine, and increasing design difficulty. Effects of stabilization, improved reliability and service life, and elimination of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

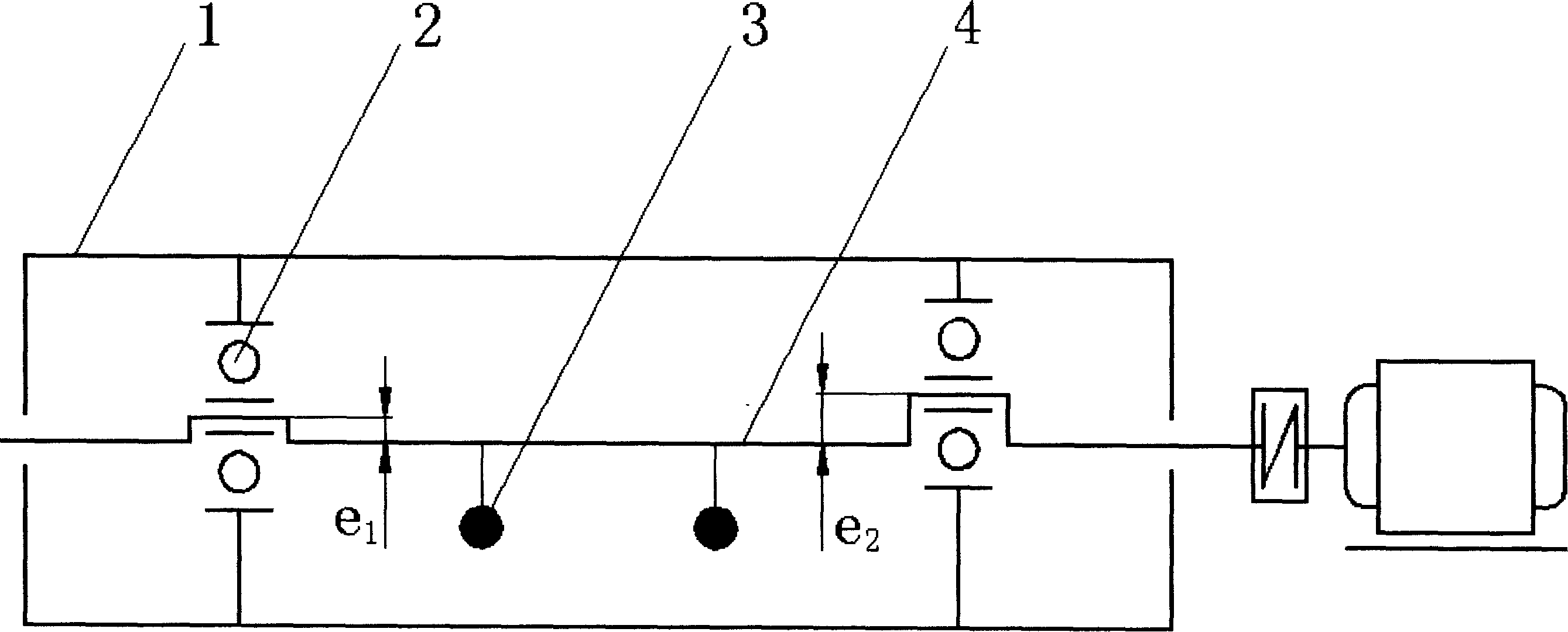

[0018] Such as figure 1 As shown, the vibrator is composed of a housing 1, a bearing 2, a balance weight 3 and an eccentric shaft 4. Both ends of the eccentric shaft 4 are sleeved with bearings 2, the housing 1 is fixedly connected to the bearing 2, the balance weight 3 is fixedly connected to the eccentric shaft 4 according to the dynamic balance condition, and the eccentric shaft 4 is connected to the power source through transmission. When the exciter is working, the eccentric shaft 4 rotates at a high speed to vibrate the housing 1, and the centrifugal force generated by the high-speed rotation of the balance weight 3 offsets the dynamic load generated by the housing 1 on the eccentric shaft 4, ensuring that the eccentric shaft 4 maintains dynamics when rotating at high speed. balance. The vibration generated by the exciter is directly transmitted to the working medium by the shell 1, and the eccentric shaft 4 that meets the dynamic balance condition does not vibrate, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com