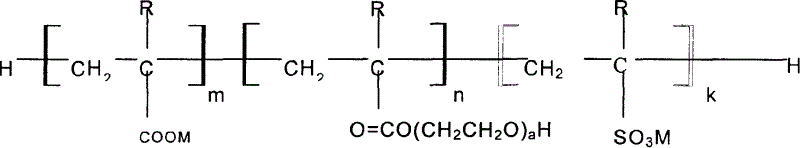

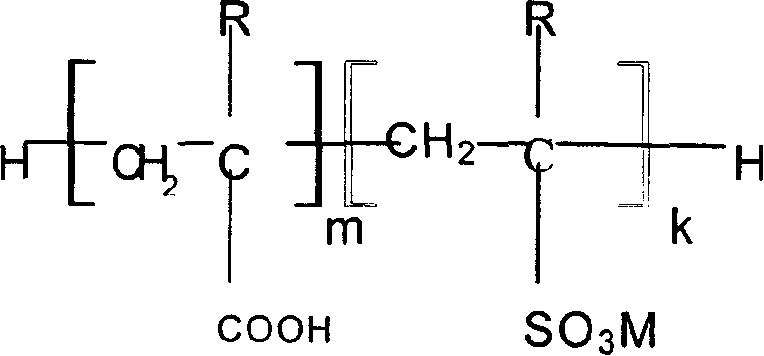

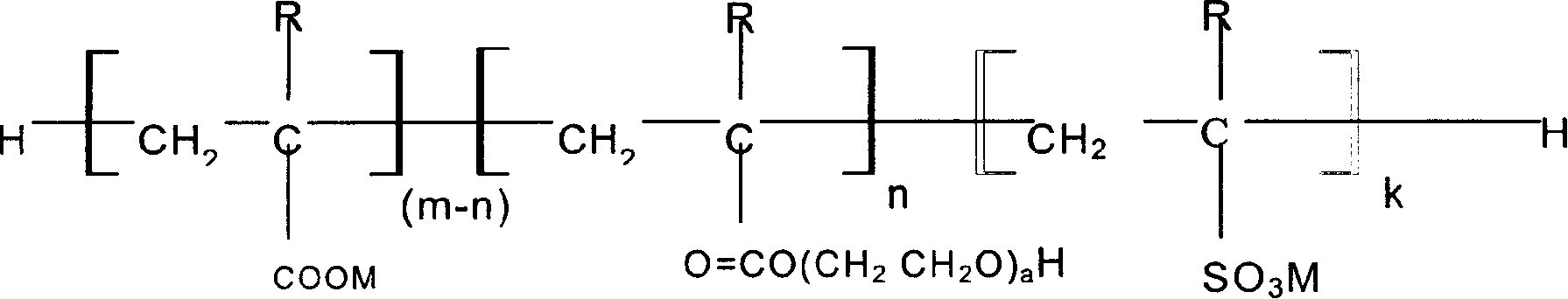

Water reducing agent of poly carboxylic acid series concrete and its preparation process

A concrete water-reducing agent and polycarboxylic acid-based technology, which are applied in the field of polycarboxylic acid-based concrete water-reducing agent and preparation, can solve the problems of high equipment requirements, complex production process, low water-reducing rate, etc. The effect of easy control of reaction conditions and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put 7.91g of sodium methacrylsulfonate into a reaction vessel, add 15.82g of water, stir evenly, raise the temperature, add 72g of acrylic acid dropwise at a temperature of 80±5°C, and add ammonium persulfate solution (0.39g ammonium persulfate and 0.79g water), the mol ratio of reaction substance sodium methacrylate and acrylic acid is 0.05: 1, and the initiator ammonium persulfate consumption is 0.5% of the total mass of sodium methacrylate and acrylic acid. Acceleration, the drop is completed within 90 minutes, keep the temperature at 85±5°C, and react for another 6.5 hours. Then add polyethylene glycol 100g with a molecular weight of 1000, p-toluenesulfonic acid 1.79g, wherein the molar ratio of polyethylene glycol and acrylic acid used is 0.1:1, and the amount of p-toluenesulfonic acid is polyethylene glycol and active group 1% of the total mass of the polymer, stirring and continuing to heat, react for another 11 hours, stop heating, when the temperature drops to ...

Embodiment 2

[0039]Put 7.91g of sodium methacrylsulfonate into a reaction vessel, add 15.82g of water, stir evenly, raise the temperature, add 7.2g of acrylic acid dropwise at a temperature of 80±5°C, and add ammonium persulfate solution (1.51 g ammonium persulfate and 3.02g water), the mol ratio of reaction substance sodium methacrylate and acrylic acid is 0.5: 1, and the initiator ammonium persulfate consumption is 10% of sodium methacrylate and acrylic acid gross mass, control Dropping speed, the drop is completed within 90 minutes, and the temperature is maintained at 85±5°C, and the reaction is continued for 6.5 hours. Then add 60 g of polyethylene glycol with a molecular weight of 1000, and 7.5 g of p-toluenesulfonic acid, wherein the molar ratio of polyethylene glycol and acrylic acid used is 0.6: 1, and the amount of p-toluenesulfonic acid is polyethylene glycol and active groups. 10% of the total mass of the high molecular polymer, stirring and continuing to heat, and then reactin...

Embodiment 3

[0042] Put 7.91g of sodium methacrylate into a reaction vessel, add 15.82g of water, stir evenly, raise the temperature, add 36g of acrylic acid dropwise at a temperature of 80±5°C, and add ammonium persulfate solution (1.98g ammonium persulfate and 3.96g water), the mol ratio of reaction substance sodium methacrylate and acrylic acid is 0.1: 1, and the initiator ammonium persulfate consumption is 4.5% of the total mass of sodium methacrylate and acrylic acid. Acceleration, the drop is completed within 90 minutes, keep the temperature at 85±5°C, and react for another 6.5 hours. Then add 150 g of polyethylene glycol with a molecular weight of 1000, and 3.87 g of p-toluenesulfonic acid, wherein the molar ratio of polyethylene glycol and acrylic acid used is 0.3:1, and the amount of p-toluenesulfonic acid is polyethylene glycol and active group 2% of the total mass of the polymer, stirring and continuing to heat, react for another 11 hours, stop heating, when the temperature drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com