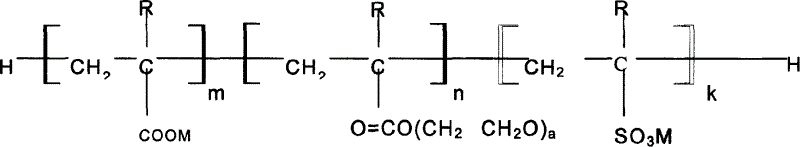

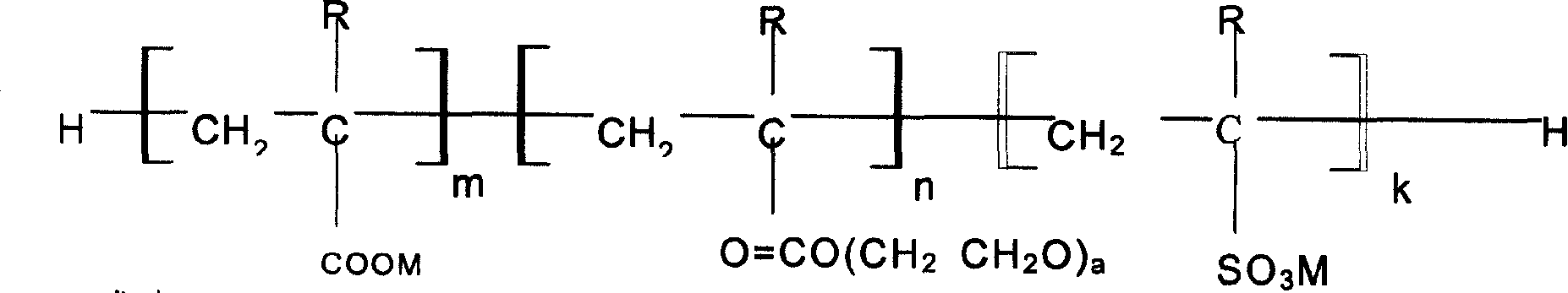

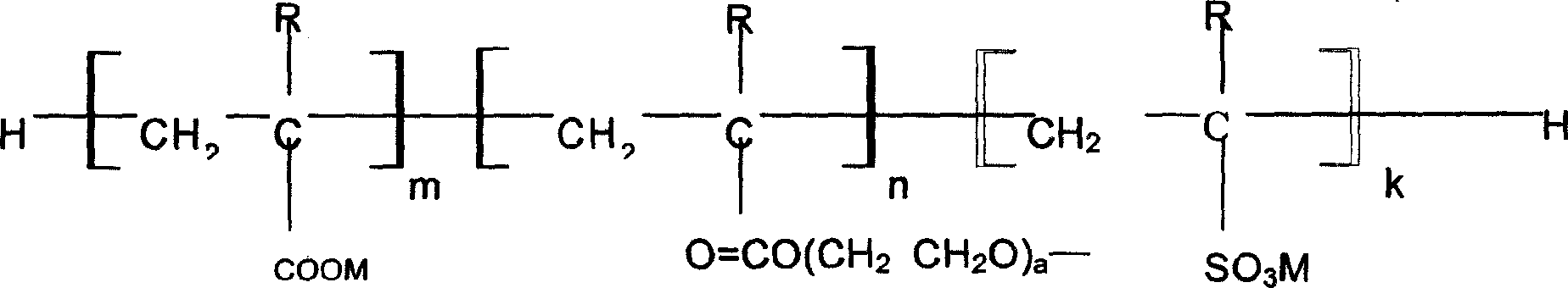

Concrete water reducing agent of polycarboxylic acid and its prepn process

A concrete water-reducing agent and a polycarboxylic acid-based technology, which are applied in the field of polycarboxylic acid-based concrete water-reducing agent and preparation, can solve the problem of low water reduction rate, and achieve stable performance, good appearance quality and strong product adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take the best ratio

[0031] Put 100.00g of polyethylene glycol with a molecular weight of 1000, 2.14g of concentrated sulfuric acid, and 100.00g of toluene into a reaction container, stir at a temperature of 80±5°C to completely dissolve the reactants, and then dropwise add 7.20g of acrylic acid into the container , control the dropping speed, finish dropping in 100±10 minutes, keep the temperature at 90±5°C, react for another 5 hours, vacuumize for 1 hour, pump out water and toluene, and react to form polyethylene glycol monoacrylate (PEA). Put 52.70g of PEA and 7.91g of sodium methacrylate into a reaction vessel, add 136.74g of water, stir evenly, raise the temperature, add 10.80g of acrylic acid dropwise at a temperature of 80±5°C, and drop by mass percentage 20.52g of 5% solution of ammonium persulfate and 9.36g of 10% solution of mercaptoethanol by mass percentage, the rate of addition was controlled, and the drop was completed in 100 ± 10 minutes, and the tempera...

Embodiment 2

[0033]Put 100g of polyethylene glycol with a molecular weight of 1000, 1.07g of concentrated sulfuric acid and 100g of toluene into a reaction container, stir at a temperature of 80±5°C to completely dissolve the reactants, then add 7.2g of acrylic acid dropwise to the container, and control The dropping speed is finished in 100±10 minutes, keep the temperature at 90±5°C, react for another 5 hours, vacuumize for 1 hour, pump out water and toluene, and react to form polyethylene glycol monoacrylate (PEA). Put 52.70g of PEA and 7.91g of sodium methacrylate into a reaction vessel, add 136.74g of water, stir evenly, raise the temperature, add 10.80g of acrylic acid dropwise at a temperature of 80±5°C, and add 5% by mass 20.52g of ammonium persulfate solution and 9.36g of mercaptoethanol solution with a mass percentage of 10%, the dropping speed is controlled, and the drop is completed in 100±10 minutes, and the temperature is maintained at 85±5°C, and then reacted for 6 hours. Aft...

Embodiment 3

[0035] Put 100.00g of polyethylene glycol with a molecular weight of 1000, 2.14g of concentrated sulfuric acid and 100.00g of toluene into a reaction container, stir at a temperature of 80±5°C to completely dissolve the reactant, then add 7.20g of acrylic acid dropwise to the container , control the dropping speed, finish dropping in 100±10 minutes, keep the temperature within the range of 90±5°C, react for another 5 hours, vacuumize for 1 hour, pump out water and toluene, and react to form polyethylene glycol monoacrylate (PEA ). Put 52.70g of PEA and 7.91g of sodium methacrylate into a reaction container, add 143.58g of water, stir evenly, raise the temperature, add 10.80g of acrylic acid dropwise at a temperature of 80±5°C, and add a mass percentage of 5 13.68g of the solution ammonium persulfate and 9.36g of the 10% solution of mercaptoethanol by mass percentage, the rate of addition was controlled, and the drop was completed in 100 ± 10 minutes, and the temperature was ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com