High-performance multifunctional cement reducing agent for concrete and preparation method for same

A high-performance concrete and multi-functional technology, applied in the field of concrete admixture, can solve the problems of increased hazard of alkali aggregate, increased structural shrinkage and deformation, poor crack resistance and seepage resistance, etc., to improve frost resistance and Effects of anti-carbonization, improved pumpability, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

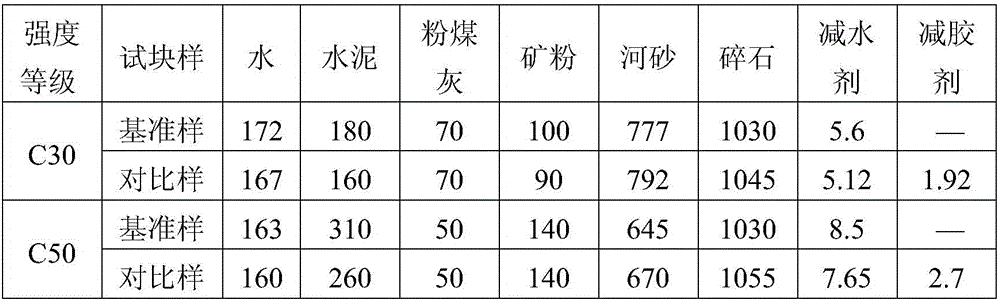

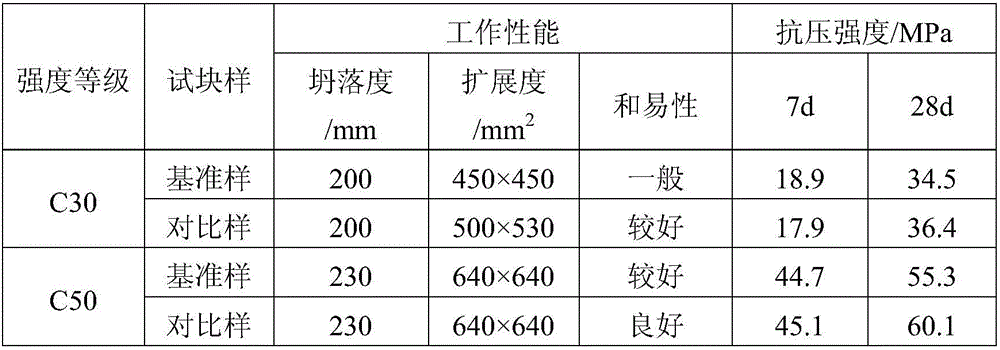

Embodiment 1

[0023] In terms of mass percentage, weigh 15% isopentenol polyoxyethylene ether, 20% triisopropanolamine, 5% ethylene glycol, 3% acrylic acid, 0.3% polyether modified siloxane (polyether modified siloxane), 0.1% hydrogen peroxide (hydrogen peroxide), and the balance is water, put into a reaction vessel, stir at room temperature for 2 hours, and obtain a multifunctional adhesive reducer for high-performance concrete (finished product JLK-1) .

Embodiment 2

[0025] In terms of mass percentage, weigh 15% allyl polyoxyethylene ether, 20% diethanol monoisopropanolamine, 5% glycerol, 2% methacrylic acid, 0.3% polyether modified siloxane (polyether-modified siloxane), 0.1% hydrogen peroxide, and water as the balance, put into a reaction vessel, stir at room temperature for 2 hours, and obtain a multifunctional glue reducer for high-performance concrete (finished product JLK-2).

Embodiment 3

[0027] In terms of mass percentage, weigh 15% isopentenol polyoxyethylene ether, 20% diethanol monoisopropanolamine, 5% glycerol, 2% acrylic acid, 0.3% polyether modified siloxane ( Polyether-modified siloxane), 0.3% potassium persulfate, and water as the balance, put into a reaction vessel, stir at room temperature for 2 hours, and obtain a multifunctional glue reducer for high-performance concrete (finished product JLK-3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com