Drying-method sand making device and process

A dry process and process technology, applied in the field of dry sand making equipment and process, can solve the problems of large fineness modulus, excessive needle flake shape, poor mechanical sand grain shape, etc., and achieves high yield, good grain shape, The effect of eliminating dust air pollution and wastewater discharge problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

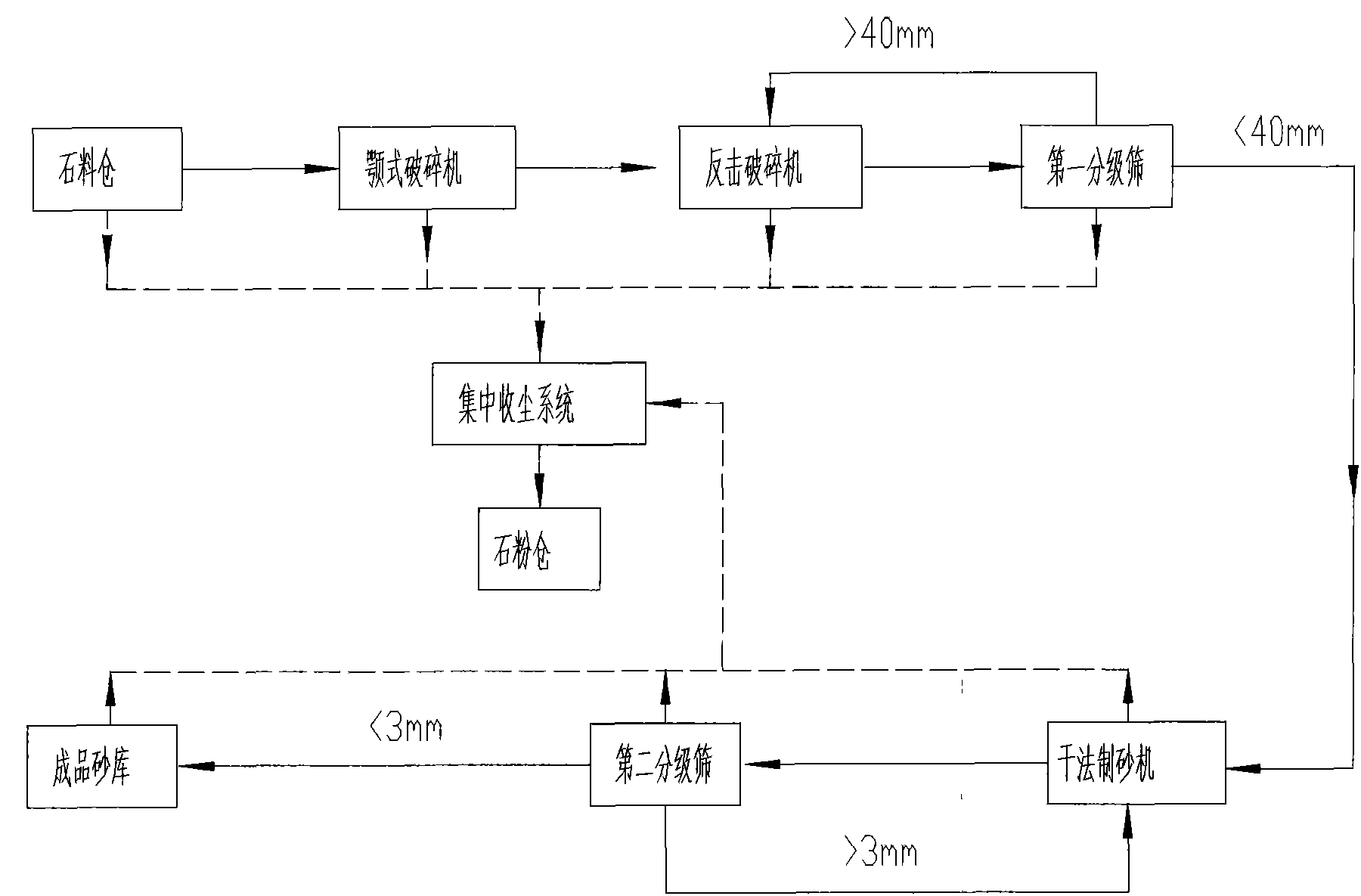

[0009] like figure 1 As shown, a dry sand making equipment and process is characterized in that it includes a jaw crusher, an impact crusher, a first classifying screen, a dry sand making machine, a second classifying screen and a centralized dust collection system; the production process route is , the stone in the stone silo is evenly sent to the jaw crusher through the feeder for the first coarse crushing, and the crushed material is transported to the impact crusher for the second fine crushing, and the crushed material enters the first classification The sieve is used for grading, the sand less than 40mm is sent to the dry sand making machine through the conveyor for crushing and sand making, and the gravel larger than 40mm is returned to the impact crusher, and the sand and gravel entering the dry sand making machine are crushed by the dry sand making machine After that, it is transported to the second grading screen for grading, the sand less than 3mm is directly sent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com