Polyester elastomer hot melt adhesives and preparation method thereof for bonding polar polymers and metallic materials

A polyester elastomer and polar polymer technology, applied in the field of polyester elastomer hot melt adhesive and its preparation, can solve the problems of metal surface degumming, hot melt adhesive can not meet the needs of use, etc., to achieve high bonding strength , long-lasting and stable bonding, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

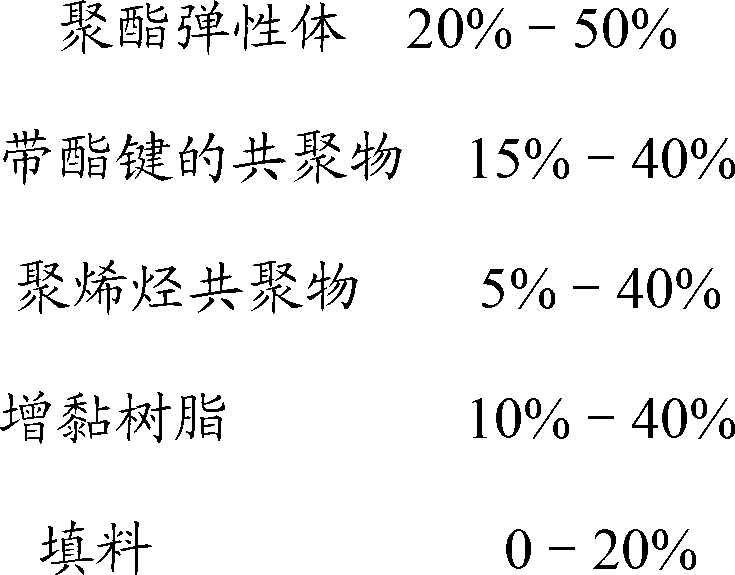

Method used

Image

Examples

Embodiment 1

[0025] 50% polyester elastomer with a melting point of 178°C (LG Chemical, KEYFLEX 1040D), 20% polyethylene-vinyl acetate copolymer (DuPont, Elvax 660), 10% polyolefin elastomer (Dow Chemical , ENGAGE 8200), 19.5% pentaerythritol rosin ester, 0.5% antioxidant 1010 (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester) with a high-speed mixer Perform mixing, extrude and granulate with an extruder at 195°C, and press the rubber granules into a hot melt adhesive film with a thickness of 0.10mm at 200°C with a flat vulcanizer. Investigate the 180° peel strength of PVC / aluminum, ABS / stainless steel, and PC / copper composited by the film at 180°C. The specific test results are shown in Table 1.

Embodiment 2

[0027] 20.5% of polyester elastomer with a melting point of 193.6°C (Chenguang Kexin, SUNPRENE TPEEH6055), 10% of copolyester (Shanghai Tianyang, PES3112), 20% of polyethylene-methyl acrylate copolymer (DuPont, Elvaloy AC 1820), 10% EPDM rubber (Dow Chemical, Nordel 4725P), 10% terpene phenolic resin, 0.5% antioxidant 1076 (β-(3,5-di-tert-butyl- 4-Hydroxyphenyl) propionate octadecyl propionate) mixed with a high-speed mixer, extruded and granulated with an extruder at 210°C, and pressed into 0.10mm thick hot Melt film. Investigate the 180°peel strength of the adhesive film at 200°C PVC / aluminum, ABS / stainless steel, PC / copper, see Table 1 for the specific test results.

Embodiment 3

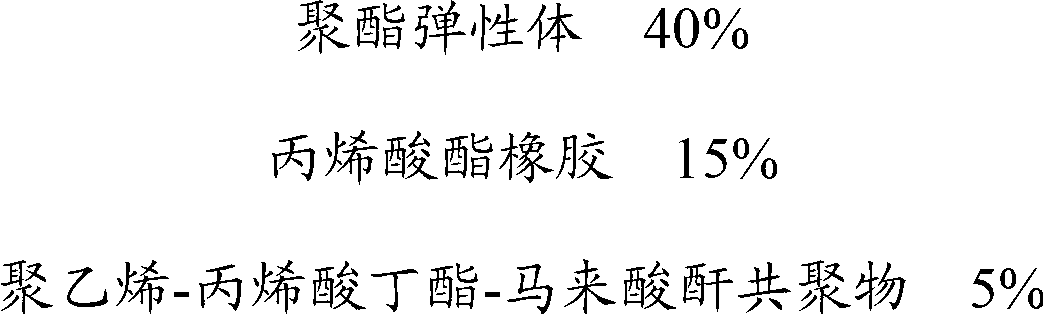

[0029] Copolymerize 20% polyester elastomer with a melting point of 150°C (LG Chemical, KEYFLEX 3140D), 20% polyurethane hot melt adhesive (Taiwan Xinshun, AH701), and 20% polyethylene-ethyl acrylate-maleic anhydride (Akema, Lotader 5500), 5% amorphous α-olefin copolymer (Degussa, APAO508), 25% hydrogenated rosin glycerides, and 10% calcium carbonate were mixed with a high-speed mixer. The extruder is extruded and granulated at 160°C, and the rubber granules are pressed into a hot-melt adhesive film with a thickness of 0.10mm at 200°C by a flat vulcanizer. Investigate the 180° peel strength of PVC / aluminum, ABS / stainless steel, and PC / copper composited by the film at 180°C. The specific test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com