Flame retardant phosphate tri(dimethyl siliconyl heterocyclic methylene) ester compound and preparation method thereof

A technology of dimethylsilylphosphonoheterocyclic methylene and trimethylol dimethylsilicate, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., capable of Solve the secondary hazards of life safety and other issues, and achieve the effect of high synergistic flame retardant efficiency, low cost, and moderate polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

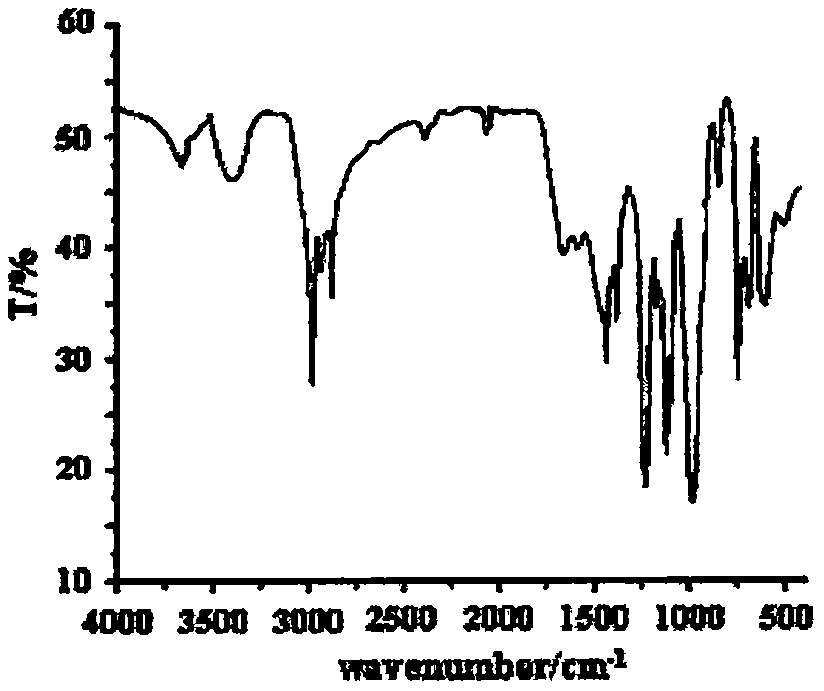

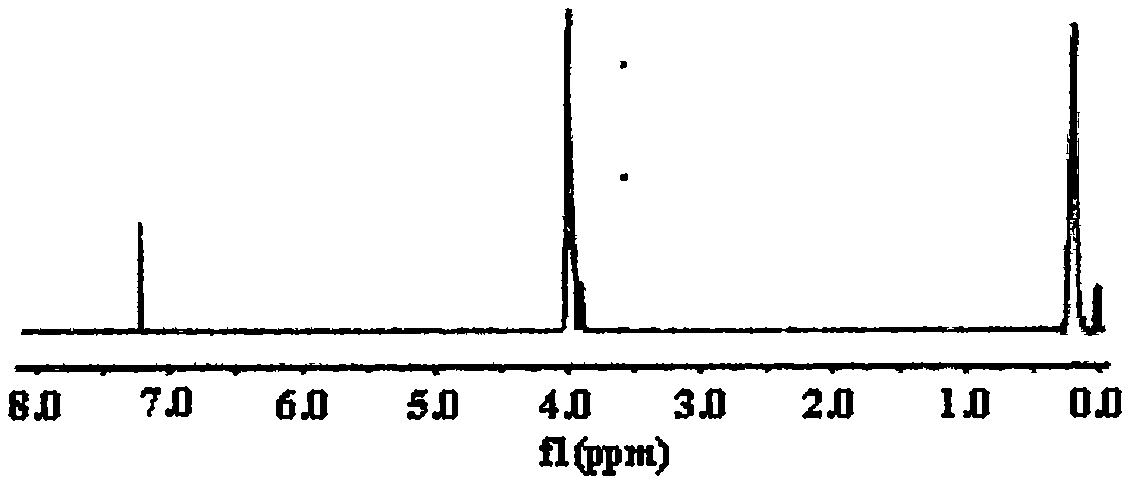

[0025] Example 1 In a 250ml four-neck flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a hydrogen chloride absorption device connected to the upper mouth of the condenser, use nitrogen to exhaust the air in the bottle, and at 20°C, add 29.4g ( 0.15mol) trimethylol phosphine oxide cyclic ester of dimethyl silicate and 90ml of diethylene glycol dimethyl ether, after the trimethylol phosphine oxide cyclic ester of dimethyl silicate is completely dissolved and dispersed, add dropwise 7.675g (0.05mol) phosphorus oxychloride, control the dripping process not to exceed 60°C, after the dropwise addition, the temperature is raised to 100°C, and the temperature is kept for 10 hours to make the hydrogen chloride completely released, and the solvent is distilled off under reduced pressure to obtain a turbid viscous liquid; The crude product was poured into 100 ml of ice water and stirred rapidly for 30 min, filtered with suction, rinsed with 50 ml of wat...

Embodiment 2

[0026] Example 2 In a 250ml four-neck flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a hydrogen chloride absorption device connected to the upper mouth of the condenser, use nitrogen to exhaust the air in the bottle, and at 20°C, add 30.38g ( 0.155mol) trimethylol phosphine oxide cyclic ester of dimethyl silicate and 120ml anisole, after the trimethylol phosphine oxide cyclic ester of dimethyl silicate is completely dissolved and dispersed, add 7.675g (0.05 mol) phosphorus oxychloride, control the dropping process not to exceed 60°C, raise the temperature to 130°C after dropping, keep the temperature for 9 hours, let the hydrogen chloride be released, and distill off the solvent under reduced pressure to obtain a turbid viscous liquid; then pour the crude product into Stir rapidly in 100 ml of ice water for 30 min, filter with suction, rinse with 50 ml of water, and vacuum-dry the filter cake to obtain the product tris(dimethylsilylphosphon...

Embodiment 3

[0027] Example 3 In a 250ml four-necked flask equipped with a stirrer, a thermometer, a high-efficiency reflux condenser and a hydrogen chloride absorption device connected to the upper mouth of the condenser, the air in the bottle was exhausted with nitrogen, and at 20°C, 31.36g ( 0.16mol) trihydroxymethylphosphine oxide dimethylsilicate cyclic ester and 140ml xylene, after the trimethylolphosphine oxide cyclic ester dimethylsilicate is completely dissolved and dispersed, add 7.675g (0.05mol ) phosphorus oxychloride, control the dropping process not to exceed 60°C, raise the temperature to 120°C after dropping, keep the temperature for 9 hours, let the hydrogen chloride be released, and distill off the solvent under reduced pressure to obtain a turbid viscous liquid; then pour the crude product into 100ml Stir rapidly in ice water for 30 min, filter with suction, rinse with 50 ml of water, and dry the filter cake in vacuum to obtain the product tris(dimethylsilylphosphonoheter...

PUM

| Property | Measurement | Unit |

|---|---|---|

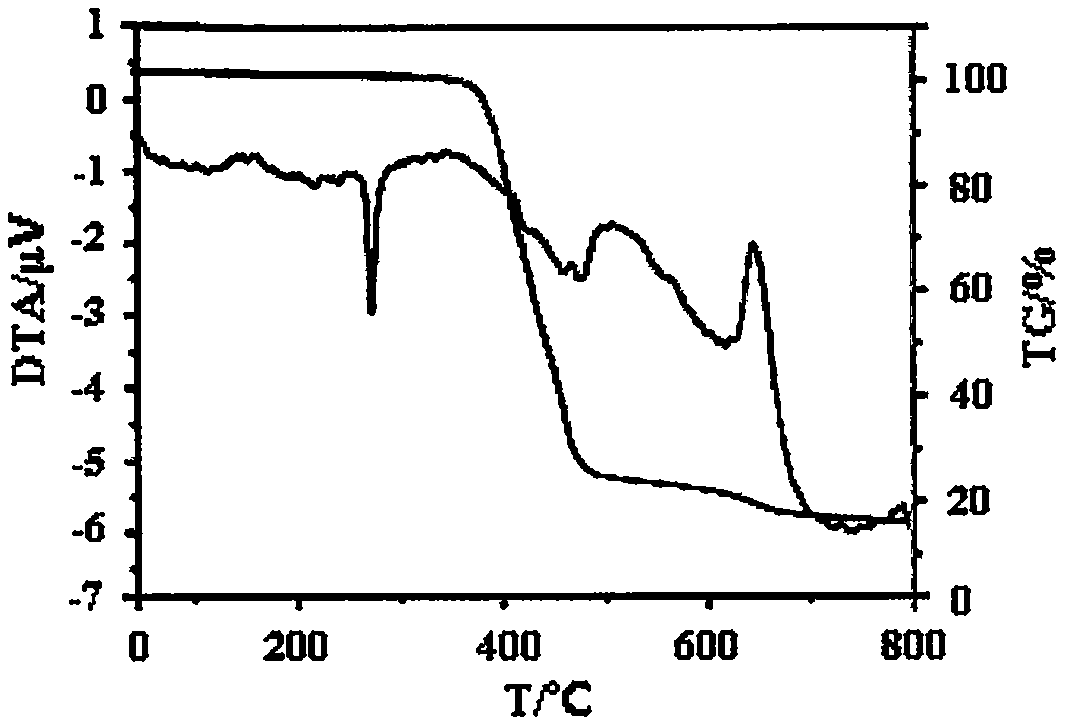

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com