High-temperature-resistant paper-plastic laminating adhesive and preparation method thereof

A laminating adhesive and high temperature resistant technology, which is applied in the direction of adhesives, epoxy resin adhesives, non-polymer adhesive additives, etc., can solve the problems of application limitations, bond strength needs to be improved, and sticky surface of the bonded surface, etc., to achieve The effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

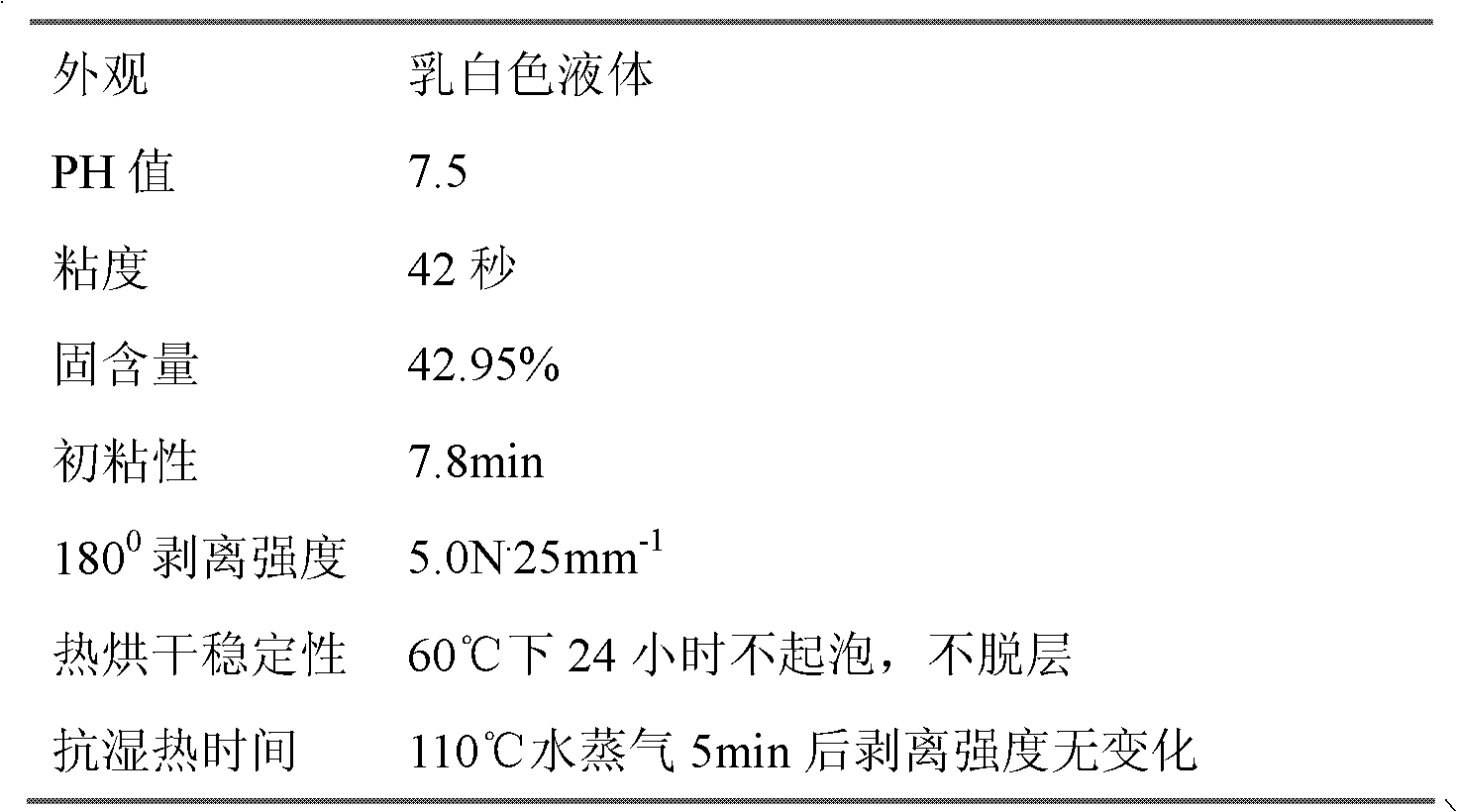

Embodiment 1

[0044] (1) get the EVA resin of 15g, 4g carnauba wax, 3g South African Sasol wax, the mixture of 3g ozokerite drops into the reactor together, 120 ℃, stirring speed are that EVA resin and mixed wax are all dissolved under 300rpm, and Add 2g of triethanolamine; take another 2g of OP-10, 2g of fatty alcohol polyoxyethylene ether (AEO), 1g of fatty alcohol polyoxyethylene ether sulfate (AES) and 2g of sodium dodecyl sulfate (SDS), and dissolve them in 64g Deionized water was slowly added to the mixed solution of EVA resin and wax under 2000rpm shear dispersion, and after dispersing for 50 minutes, a composite emulsion was obtained.

[0045] (2) Mix the composite emulsion obtained in step (1) with 10g of VAE emulsion and place it in a dispersion tank, add 0.3g of SPA-202 at room temperature at a stirring speed of 600rpm, and disperse for 10min.

[0046] (3) After adjusting the stirring speed in step (2) to 200rpm, add 6g of silicon dioxide and disperse for 90min.

[0047] (4) Kee...

Embodiment 2

[0054] (1) Get the mixture of 30g of EVA resin, 10g of beeswax, 5g of liquid paraffin, and 5g of microcrystalline wax into the reactor together, dissolve the EVA resin and mixed wax at 60°C and a stirring speed of 400rpm, and add 3g of three Ethanolamine; another 4g fatty alcohol polyoxyethylene ether (AEO), 2g sodium dodecylbenzenesulfonate (SDBS), 3g sodium dodecyl sulfate (SDS), 2g alkylphenol polyoxyethylene (10) ether (OP-10) and dissolved in 96g deionized water together, slowly added to the mixture of EVA resin and mixed wax under 3000rpm shear dispersion, after dispersing for 30min, a composite emulsion was obtained.

[0055] (2) Mix the composite emulsion obtained in step (1) and 15g of VAE emulsion and place it in a dispersion tank, add 0.1g of BKY-045 and 0.2g of DEUCHEM090 at room temperature at a stirring speed of 1000rpm, and disperse for 60min.

[0056] (3) After adjusting the stirring speed in step (2) to 300 rpm, add 5 g of kaolin and 5 g of pottery clay, and d...

Embodiment 3

[0064] (1) Take 5g of EVA resin and 30g of modified montan wax mixture and put them into the reactor together, melt the EVA resin and wax at 100°C and a stirring speed of 500rpm, and add 5g of triethanolamine; another 2g of Tween-20 , 2gSpan-20, 1g fatty alcohol polyoxyethylene ether sulfate (AES), 1g sodium dodecyl sulfate (SDS) and dissolved in 73g deionized water together, slowly added to EVA resin and In the mixed solution of mixed wax, after dispersing for 30 minutes, a composite emulsion was obtained.

[0065] (2) Mix the composite emulsion obtained in step (1) and 12g of VAE emulsion and place it in a dispersion tank, add 0.4g of DEUCHEM091 at room temperature at a stirring speed of 1000rpm, and disperse for 15min.

[0066] (3) After adjusting the stirring speed in step (2) to 300rpm, add 8g of light calcium carbonate and disperse for 80min.

[0067] (4) Keep the stirring speed in (3) constant, and add 10 g of aqueous rosin glyceride emulsion to disperse for 15 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com