Manufacturing method of non-woven needle-punched jacquard pad

A non-woven needle punching and manufacturing method technology, applied in the direction of punching pattern, textile and paper making, roughening, etc., can solve the problems of high strength, low elongation, complicated preparation method, etc., achieve high strength, improve strength, flatness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

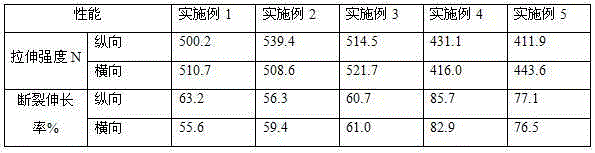

Examples

Embodiment 1

[0021] A method for making a non-woven needle-punched jacquard pad, comprising the following steps:

[0022] (1) Put the polyester fiber and polypropylene fiber into the opening machine for opening, and send the opened fiber raw materials into the cotton blending machine and mix them evenly;

[0023] (2) Send the mixed fiber raw materials into a carding machine to be carded into a fiber web, and the output speed of the carding machine is 2.5m / min;

[0024] (3) Convey the fiber web to the web-laying machine, and lay it into a 16-layer multi-layer fiber web;

[0025] (4) Send the multi-layer fiber web to the needling machine for needling, including needling on the front and back;

[0026] (5) Send the above-mentioned fiber web obtained after needle punching to a roller press for rolling forming;

[0027] (6) Fleece the fiber web obtained in step (5) and needle-puncture jacquard to obtain a non-woven needle-punched jacquard mat;

[0028] The weight ratio of polyester fibers an...

Embodiment 2

[0037] A method for making a non-woven needle-punched jacquard pad, comprising the following steps:

[0038] (1) Put the polyester fiber and polypropylene fiber into the opening machine for opening, and send the opened fiber raw materials into the cotton blending machine and mix them evenly;

[0039] (2) Send the mixed fiber raw materials into a carding machine to be carded into a fiber web, and the output speed of the carding machine is 2.8m / min;

[0040] (3) Convey the fiber web to the web-laying machine, and lay it into a 20-layer multi-layer fiber web;

[0041] (4) Send the multi-layer fiber web to the needling machine for needling, including needling on the front and back;

[0042] (5) Send the above-mentioned fiber web obtained after needle punching to a roller press for rolling forming;

[0043] (6) Fleece the fiber web obtained in step (5) and needle-puncture jacquard to obtain a non-woven needle-punched jacquard mat;

[0044] The weight ratio of polyester fibers an...

Embodiment 3

[0053] A method for making a non-woven needle-punched jacquard pad, comprising the following steps:

[0054] (1) Put the polyester fiber and polypropylene fiber into the opening machine for opening, and send the opened fiber raw materials into the cotton blending machine and mix them evenly;

[0055] (2) Send the mixed fiber raw materials into a carding machine to be carded into a fiber web, and the output speed of the carding machine is 3.0m / min;

[0056] (3) Convey the fiber web to the web-laying machine, and lay it into a 24-layer multi-layer fiber web;

[0057] (4) Send the multi-layer fiber web to the needling machine for needling, including needling on the front and back;

[0058] (5) Send the above-mentioned fiber web obtained after needle punching to a roller press for rolling forming;

[0059] (6) Fleece the fiber web obtained in step (5) and needle-puncture jacquard to obtain a non-woven needle-punched jacquard mat;

[0060] The weight ratio of polyester fibers an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Needling density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com