Method for manufacturing lens

A lens and correction lens technology, applied in manufacturing tools, glass pressing, glass manufacturing equipment, etc., can solve the problems of poor surface accuracy, reduced productivity, and increased cost of glass lenses, and achieve significant improvement in surface accuracy and difficulty in shape forming. Large, fine surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

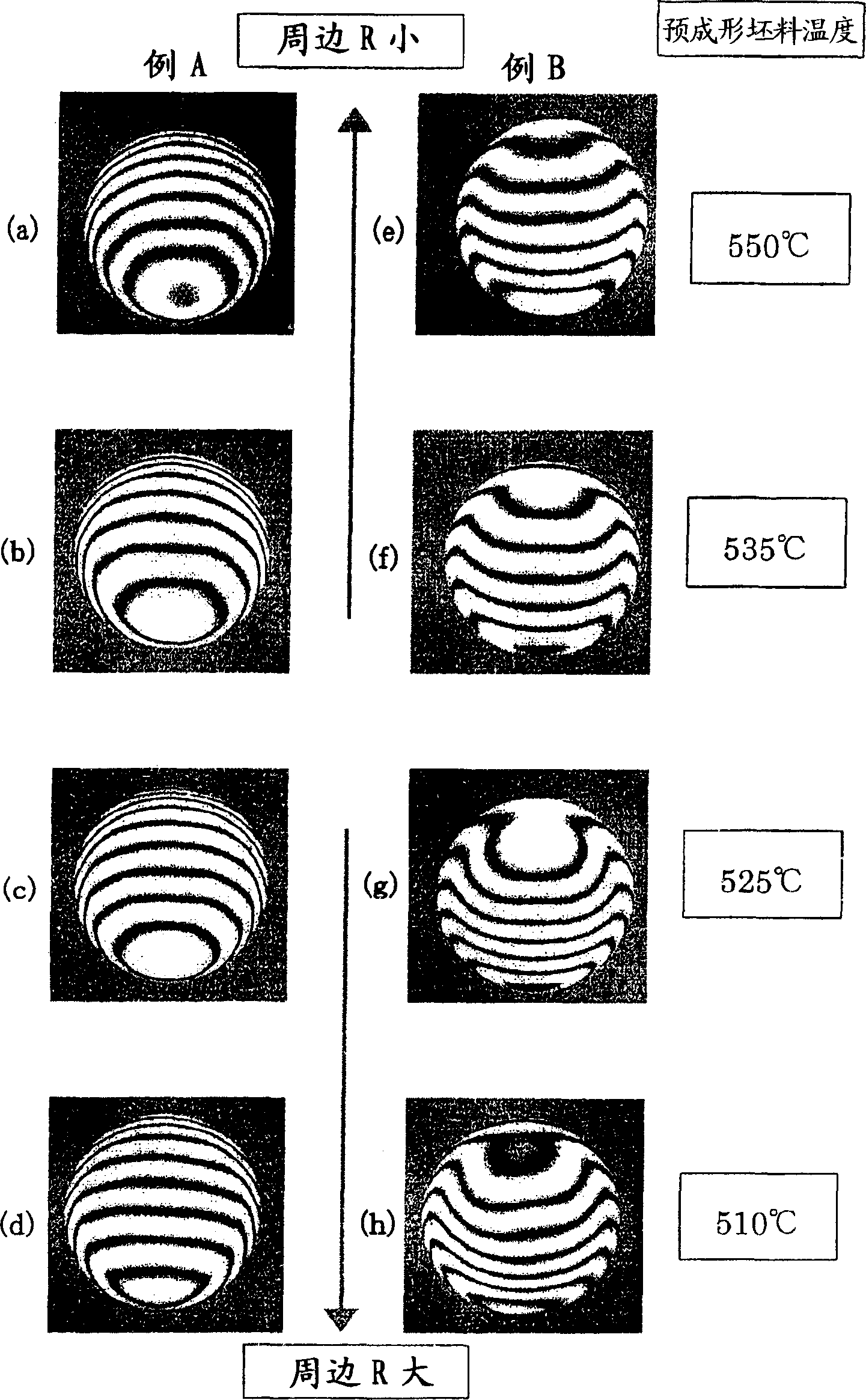

[0154] [Example 1] (Change in distortion caused by glass raw material temperature)

[0155] A concave meniscus lens with a diameter of 11 mm and a central plate thickness of 1.2 mm was molded, and the first surface and the second surface were spherical. Preform phosphate glass feedstock (Tg: 450Ts: 490°C) into a diameter of 10mm and a volume of 420mm 3 The flat spherical shape is used as the preform blank. Bring it to a viscosity of 10 7 ~10 9 After heating at various temperatures (550-510°C) of dPaS, it is provided to heat until the glass viscosity is equivalent to 10 9 The temperature of dPaS (510°C) and the equivalent of 10 according to the glass viscosity 10 Immediately raise the lower die between the upper and lower dies at dPaS temperature (490°C) to press the preform between the upper and lower dies with an initial pressure of 150kg / cm 2 , Cooling begins after the pressure processing starts (the cooling speed of the upper and lower molds is 100°C / min). The lower m...

Embodiment 2

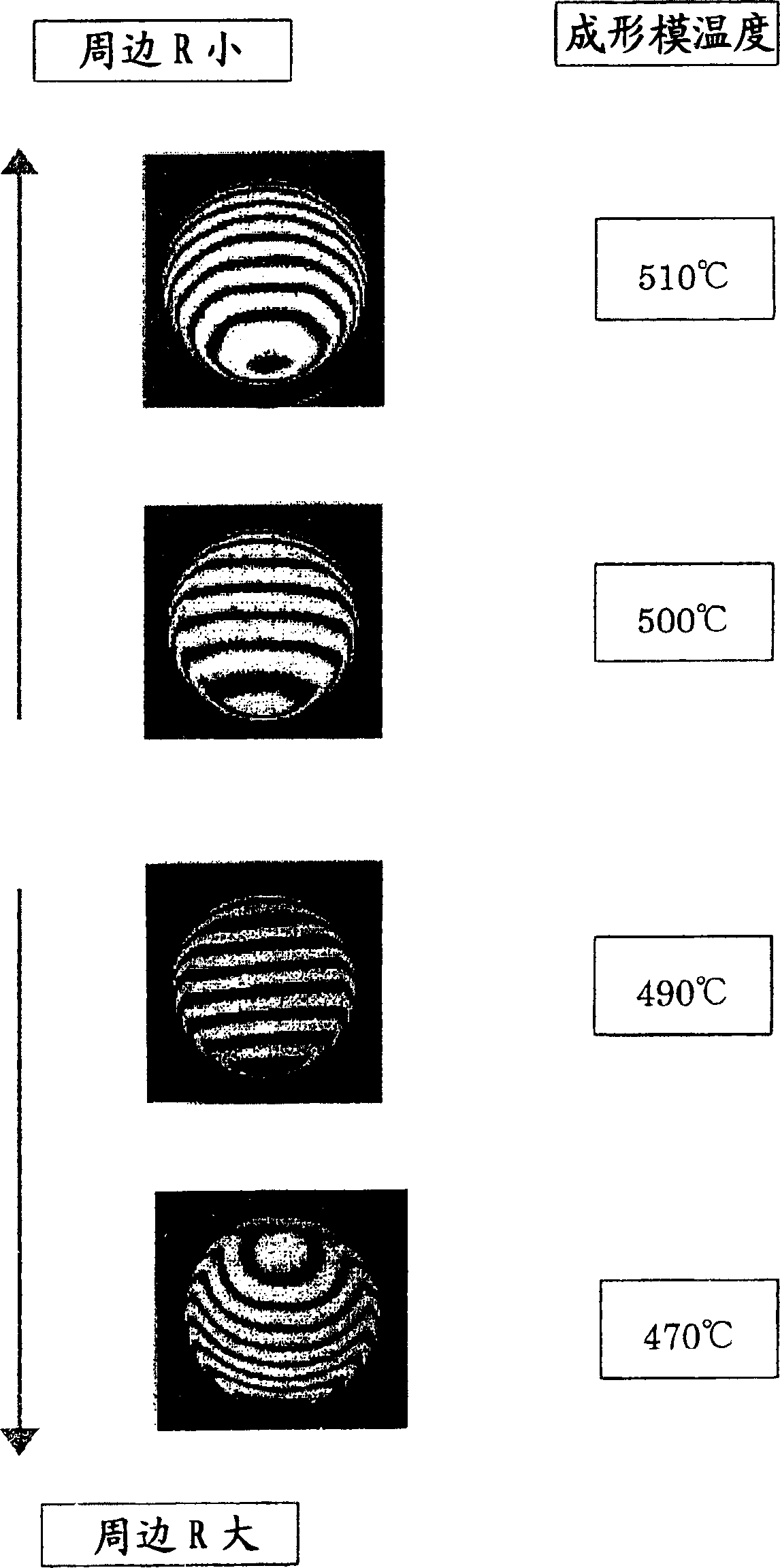

[0158] [Example 2] (Change in distortion caused by mold temperature)

[0159] Using the same preform and forming die as in Example 1, the preform is equivalent to 10 according to the glass viscosity. 7 After heating at the temperature of dPaS (550°C), it is heated to a glass viscosity of 10 9 ~10 11 The lower mold at a temperature of dPaS (470-510° C.) raises the lower mold immediately, and press-works the preform between the upper and lower molds. Press working pressure, press working procedure are identical with embodiment 1. In addition, the temperature of the upper and lower molds was set to be the same, the cooling rate of both the upper and lower molds was 100°C / min, and the second pressurization was 460°C. Such as image 3 As shown, when the mold temperature is high, the surface shape is such that the radius of curvature of the peripheral part is smaller than that of the central part. On the contrary, as the temperature decreases, the radius of curvature of the peri...

Embodiment 3

[0160] [Example 3] (Change in distortion caused by temperature difference between upper and lower dies and cooling rate difference)

[0161] Using the same preform and forming die as in Example 1, the preform is equivalent to 10 according to the glass viscosity. 7 After heating at the temperature of dPaS (550°C), it is heated to a glass viscosity of 10 9 ~10 11 The lower mold (mold for forming the first surface) at a temperature of dPaS (490 to 505°C) immediately raises the lower mold, and the preform Formed blanks are press-worked. The pressure processing procedure is the same as that of Example 1, but the cooling rate after the pressure processing is changed to 80°C / min for the upper die and 75-105°C / min for the lower die.

[0162] Such as Figure 4 As shown, there is such a tendency that if the temperature of the lower mold at the start of press working is relatively lower than that of the upper mold, the surface shape is such that the radius of curvature of the periphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com