Low-density ash silicon plate produced with industrial wastes as raw materials and production process of ash silicon plate

A technology of industrial waste and production process, applied in the field of building materials, can solve problems such as difficult construction, and achieve the effects of light handling, superior thermal insulation performance, and easy processing and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

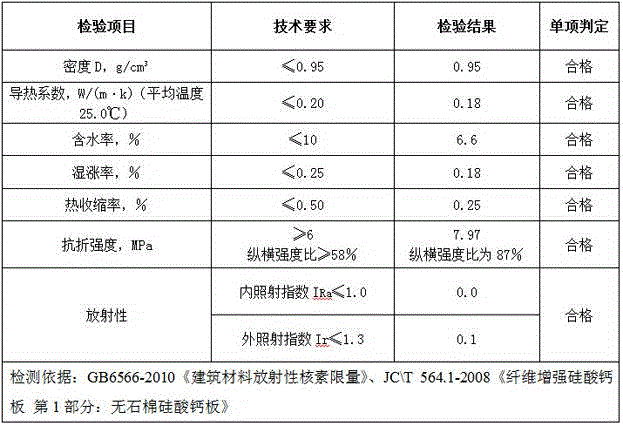

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0021] A thermal power plant in Jiangxi Province discharges a large amount of fly ash, which occupies land, pollutes the environment, and has formed a public nuisance around the power plant. After testing, the composition of the fly ash discharged from the power plant For: SiO 2 53.77%, AL 2 o 3 27.47%, Fe 2 o 3 3%, TiO 2 0.08%, CaO 1.12%, MgO 1.09%, K 2 O is 2.12%, Na 2 O is 0.20%, SO 3 is 1.54%, the loss on ignition of the fly ash is 9.22%, and the fineness is 0.06mm; 2 o 3 0.5%, MgO 0.8%, Al 2 o 3 2.23%, SiO 2 The loss on ignition of the calcium carbide slag is 3.75%, and the calcium carbide slag does not contain carbon particles, and the fineness is 0.05mm. This embodiment is a gray silicon board produced by using the fly ash and carbid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com