Preparation method of porous copper-based shape memory alloy

A technology of memory alloy and porous copper, which is applied in the field of preparation of porous copper-based shape memory alloy, can solve the problems of low production safety and high production cost, and achieve the effects of reducing production cost, excellent rolling formability and increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The first step, the preparation of Cu-Al-Mn pre-alloyed powder:

[0043] Weigh raw material pure Cu powder, pure Al powder and pure Mn powder and carry out batching respectively according to need, and wherein pure Al powder accounts for 11.8% of Cu-Al-Mn mixed powder total mass, and pure Mn powder accounts for Cu-Al-Mn mixed powder total mass 2.4% of the mass, pure Cu powder as the matrix, adding stearic acid accounting for 0.08% of the total mass of Cu-Al-Mn mixed powder as an additive, and ball milling on a planetary ball mill for 8 hours under the protection of argon, the balls used in ball milling The material ratio is 10:1, and the rotating speed of the ball mill is 300 revolutions / minute, thus making Cu-Al-Mn pre-alloyed powder;

[0044] The second step, the preparation of the green body:

[0045] The Cu-Al-Mn pre-alloyed powder prepared in the first step is uniformly mixed with absolute ethanol accounting for 6% of its mass, and then uniformly mixed with decryst...

Embodiment 2

[0054] The first step, the preparation of Cu-Al-Mn pre-alloyed powder:

[0055] Weigh raw material pure Cu powder, pure Al powder and pure Mn powder and carry out batching respectively according to need, and wherein pure Al powder accounts for 11.9% of Cu-Al-Mn mixed powder total mass, and pure Mn powder accounts for Cu-Al-Mn mixed powder total mass 2.5% of the mass, pure Cu powder as the matrix, adding stearic acid accounting for 0.1% of the total mass of Cu-Al-Mn mixed powder as an additive, and ball milling on a planetary ball mill for 10 hours under the protection of argon, the balls used in ball milling The material ratio is 10:1, and the rotating speed of the ball mill is 300 rpm, thus making Cu-Al-Mn pre-alloyed powder;

[0056] The second step, the preparation of the green body:

[0057] The Cu-Al-Mn pre-alloyed powder prepared in the first step is uniformly mixed with absolute ethanol accounting for 7% of its mass, and then uniformly mixed with decrystallized water N...

Embodiment 3

[0067] Except that in the second step, the amount of decrystallization water NaCl particles accounts for 65% of the volume percentage of the mixture of Cu—Al—Mn prealloyed powder and decrystallization water NaCl particles, the others are the same as in Example 2.

[0068] The porous CuAlMn shape memory alloy product prepared in this embodiment has a through-hole structure, with an average porosity of 65.0% and an average pore diameter of 0.56 mm.

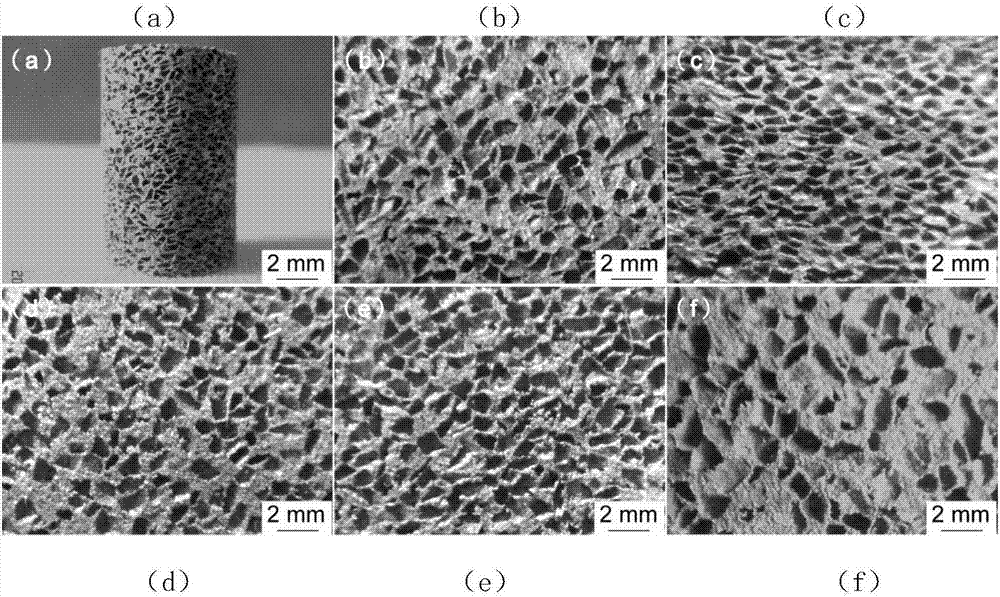

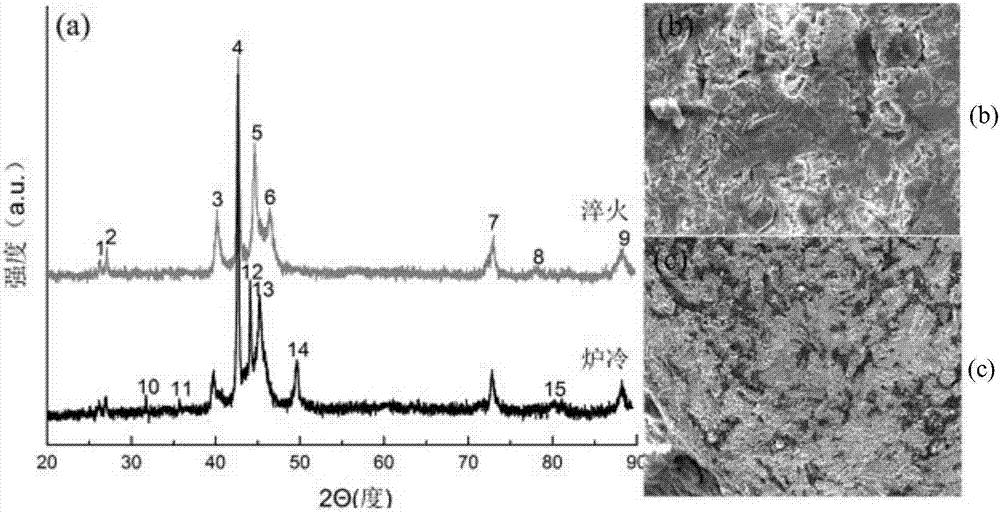

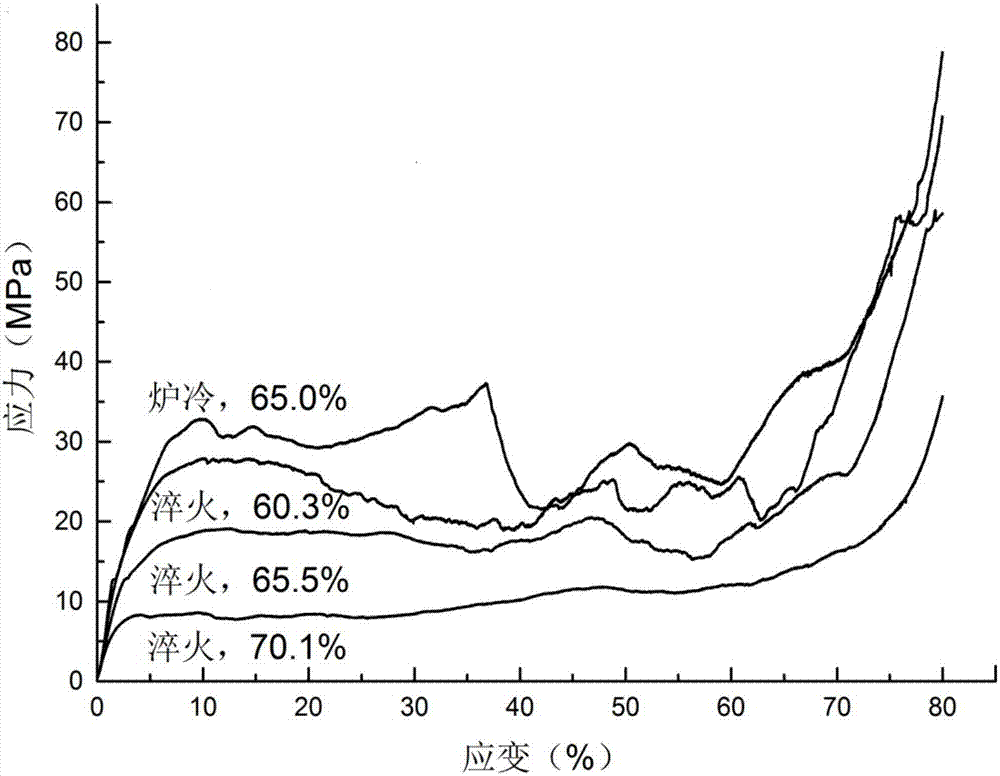

[0069] figure 1 (a) shows that the porosity obtained in this embodiment is 65.0%, and the average pore diameter is a macroscopic photo of the porous CuAlMn shape memory alloy of 0.56mm; figure 1 (b) shows the macroscopic topography photograph of the cross-section of the product that the present embodiment makes; figure 1 (c) show the macroscopic topography photo of the longitudinal section of the product made in this embodiment; figure 2 Show the porosity 65% that the present embodiment makes, average pore diameter 0.56mm porou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com