Production method of starch noodles

A production method and technology for vermicelli, applied in the fields of application, food preparation, food science, etc., can solve the problems of vermicelli or vermicelli being intolerant to cooking, poor viscosity of refined starch, sour taste of vermicelli or vermicelli, etc., so as to shorten the production cycle and improve the production. Efficiency, not easy to boil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 4 kg of water to 2 kg of mung bean starch, stir to form a thin powder paste, pour boiling water into the thin powder paste instantly, and stir to obtain a transparent thick powder;

[0031] Mix the above-mentioned thicken powder, 20kg mung bean starch, 80kg market-bought high-grade potato starch and 50kg water, and put them into a dough mixer to knead the noodles to obtain dough;

[0032] After the dough is steamed by an air steamer, formed by a molding machine, and leaked by a powder leaking machine, the formed vermicelli is obtained, and the formed vermicelli is soaked in cold water for 1 hour to obtain soft vermicelli;

[0033] The soft vermicelli was placed in a freezer, frozen at -8°C for 10 h, and after drying, transparent, smooth vermicelli without spots was obtained.

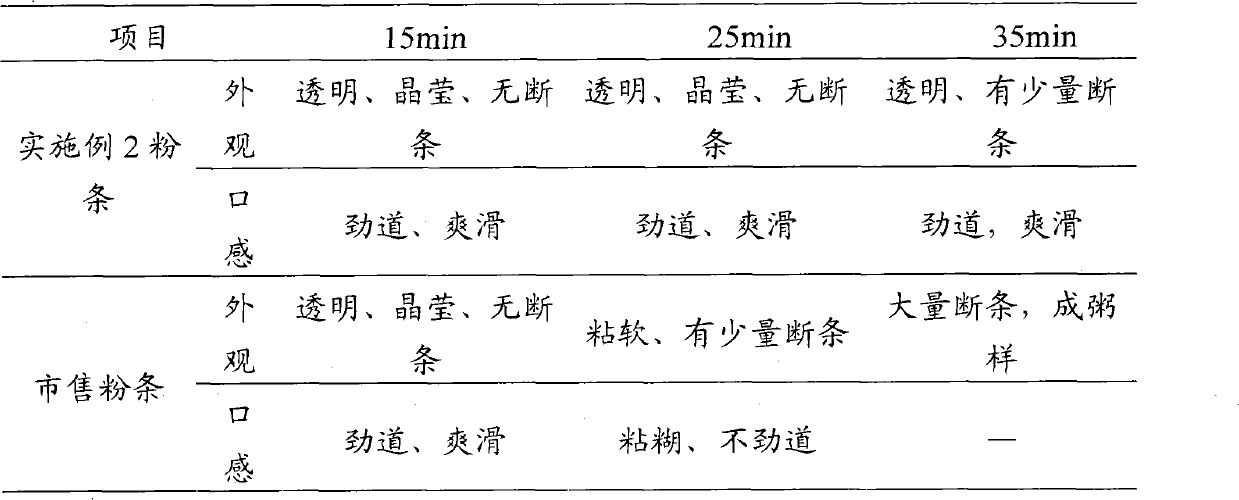

Embodiment 2

[0035] Add 4 kg of water to 2 kg of mung bean starch, stir to form a thin powder paste, pour boiling water into the thin powder paste instantly, and stir to obtain a transparent thick powder;

[0036] Mix the above-mentioned thicken powder, 25kg mung bean starch, 75kg market-bought high-grade potato starch and 50kg water, and put it into a dough mixer to knead the noodles to obtain dough;

[0037] After the dough is steamed by an air steamer, formed by a molding machine, and leaked by a powder leaking machine, the formed vermicelli is obtained, and the formed vermicelli is soaked in cold water for 1 hour to obtain soft vermicelli;

[0038] The soft vermicelli was placed in a freezer, frozen at -5°C for 15 hours, and after drying, transparent, smooth vermicelli without spots was obtained.

Embodiment 3

[0040] Add 4 kg of water to 2 kg of mung bean starch, stir to form a thin powder paste, pour boiling water into the thin powder paste instantly, and stir to obtain a transparent thick powder;

[0041] Mix the above-mentioned thicken powder, 30kg mung bean starch, 70kg market-bought high-grade potato starch and 50kg water, and put them into a dough mixer to knead the noodles to obtain dough;

[0042] After the dough is steamed by an air steamer, formed by a molding machine, and leaked by a powder leaking machine, the formed vermicelli is obtained, and the formed vermicelli is soaked in cold water for 1 hour to obtain soft vermicelli;

[0043] The soft vermicelli is placed in a refrigerator, frozen at -15° C. for 10 h, and after drying, a transparent, smooth vermicelli without spots is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com