Bio-degradable sustained-release carbon material and preparation method thereof

A technology of biodegradation and carbon materials, which is applied in the field of slow-release carbon source materials and its preparation, can solve the problems of denitrification efficiency decline, microbial metabolic function decline, and treatment efficiency decline, so as to overcome the decline of microbial metabolic function and slow-release stability Long-lasting, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0030] The present invention will be further described in detail in conjunction with the following specific embodiments and accompanying drawings. The process, conditions, experimental methods, etc. for implementing the present invention, except for the content specifically mentioned below, are common knowledge and common knowledge in this field, and the present invention has no special limitation content.

[0031]In the process of the invention, slow-release carbon materials with different material ratios are prepared, and static carbon release performance tests and denitrification performance tests are performed on them.

[0032] 1. Static carbon release performance test

[0033] The specific implementation is as follows:

Embodiment 1

[0035] Prepare the slow-release carbon material according to the following method:

[0036] (1) First pour 100mL of distilled water into a heatable container.

[0037] (2) Weigh 1gD (corn starch) and 1gQ (agar powder), place them in the above-mentioned container, stir evenly to form a suspension.

[0038] (3) Heat and boil the suspension above, and keep boiling for 5 minutes after boiling. Stir at a constant speed with a glass rod during the heating process; the total heating time is 20 minutes.

[0039] (4) After stopping the heating, pour the sol-like semi-finished product into a clean and dry container while it is hot, and condense it.

[0040] (5) After the semi-finished product is solidified, the gel-like finished product can be cut into a volume of 10cm 2 The small cube blocks are spare.

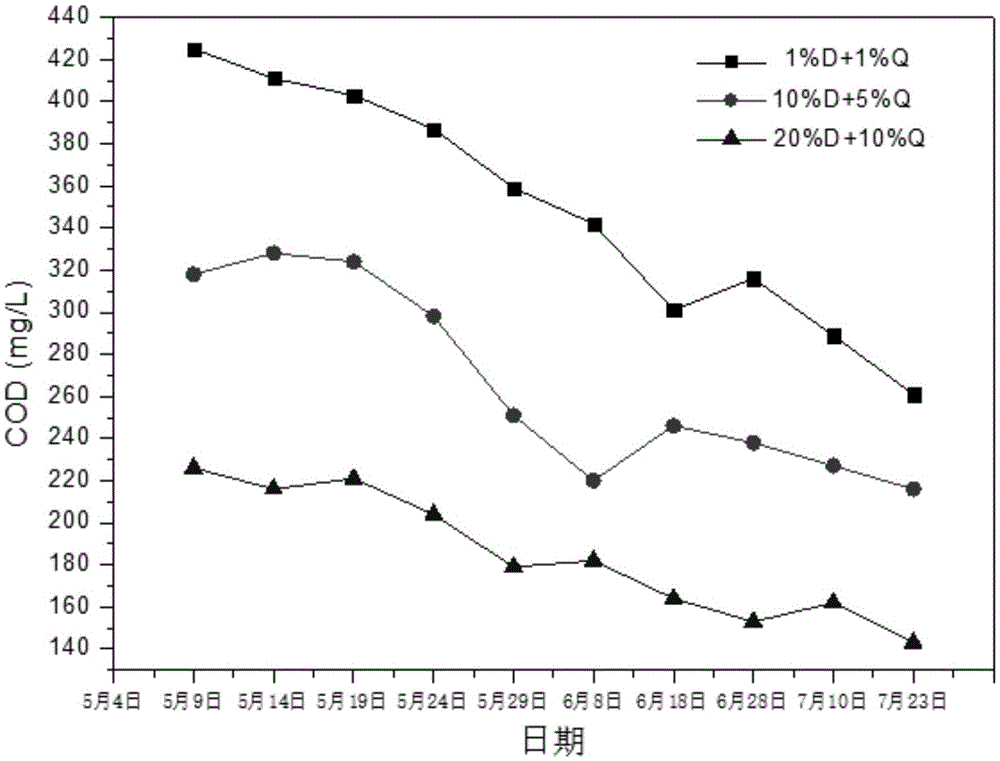

[0041] Put the prepared slow-release carbon material into a 250mL Erlenmeyer flask, add distilled water to the 250mL mark, seal it, and change the water every 5 days. Samples were...

Embodiment 2

[0045] Prepare the slow-release carbon material according to the following method:

[0046] (1) First pour 100mL of distilled water into a heatable container.

[0047] (2) Weigh 10g of D (wheat starch) and 5g of Q (agar powder), place them in the above-mentioned container, and stir to form a suspension evenly.

[0048] (3) Heat the above suspension to boiling, and keep boiling for 5 minutes after boiling. Stir at a constant speed with a glass rod during the heating process; the total heating time is 20 minutes.

[0049] (4) After stopping the heating, pour the sol-like semi-finished product into a clean and dry container while it is hot, and condense it.

[0050] (5) After the semi-finished product is solidified, the gel-like finished product can be cut into small cubes for later use.

[0051] Put the prepared slow-release carbon material into a 250mL Erlenmeyer flask, add distilled water to the 250mL mark, seal it, and change the water every 5 days. Samples were taken to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com