Method and system for preparing petroleum coke from catalytic oil slurry and ethylene tar

A technology for ethylene tar and catalytic oil slurry, which is used in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc. Deep condensed to avoid the effect of producing soft focus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

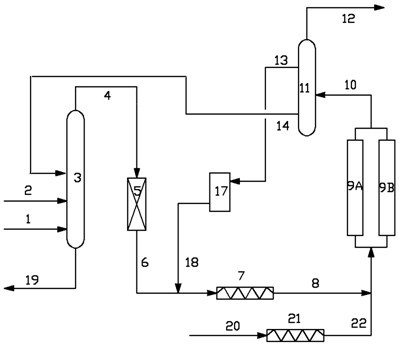

Method used

Image

Examples

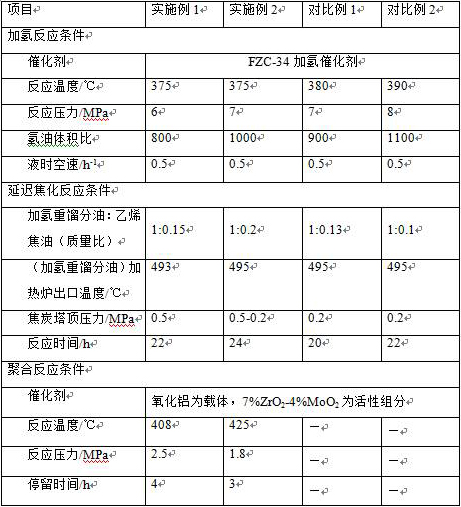

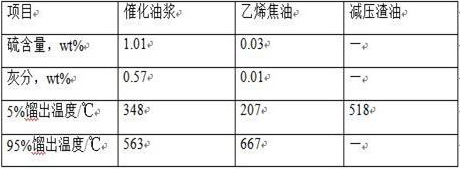

Embodiment 1

[0039] Embodiment 1 adopts the technological process of the present invention, and the catalytic oil slurry and the vacuum residue are mixed at the bottom of the vacuum distillation tower with a mass ratio of 3:1, and the 95% distillation temperature of the obtained extracted oil is 501 ° C; The hydrogen is mixed and sent to the hydrogenation reaction unit to obtain the hydrogenated heavy distillate oil; the hydrogenated heavy distillate oil and the ethylene tar are sent to the delayed coking unit according to the mass ratio of 1:0.15, and the outlet temperature of the hydrogenated heavy distillate oil heating furnace is 493 ℃ , the outlet temperature of the ethylene tar heating furnace is 298 ℃, when the feeding time reaches 30% of the reaction cycle, the feeding of ethylene tar is stopped, and the hydrogenated heavy distillate oil is separately fed into the delayed coking tower, and the delayed coking reaction adopts a constant pressure operation process; The oil and gas are ...

Embodiment 2

[0041] Embodiment 2 adopts the technological process of the present invention, and the difference from Example 1 is: the hydrogenated heavy distillate oil and the ethylene tar are sent to the delayed coking unit together according to the mass ratio of 1:0.2, and the hydrogenated heavy distillate oil heating furnace outlet The temperature is 495°C, and the outlet temperature of the ethylene tar heating furnace is 320°C. When the feeding time reaches 25% of the reaction period, the feeding of ethylene tar is stopped, and the hydrogenated heavy distillate oil is separately fed into the delayed coking tower. The delayed coking reaction adopts the pressure swing operation process. , when the feeding time reaches 50% of the reaction cycle, the coke drum pressure is released at a rate of 0.5MPa / h. The specific reaction conditions are shown in Table 2. The product distribution and coke sulfur content analysis results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com