Gasoline hydro-desulfurization method

A hydrodesulfurization and gasoline hydrogenation technology, applied in the field of gasoline hydrodesulfurization, can solve the problem of high loss of olefins in products, and achieve the effects of small loss of octane number, high desulfurization rate and high operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028]Among them, the preferred method for preparing the selective hydrogenation catalyst comprises: a) preparing an alumina carrier containing at least one selected from a δ or θ structure; b) impregnating the carrier prepared in step a) with a boron-containing aqueous solution, and drying 1. Calcining to prepare boron-surface-modified alumina carrier, the drying temperature is 90-250°C, the drying time is 0.5-12 hours, the calcination temperature is 400-700°C, and the calcination time is 0.5-14 hours; c) using at least An aqueous solution of a compound of Group VIB and at least one hydrogenation active metal component of Group VIII is impregnated separately or simultaneously with the boron-surface-modified alumina support prepared in step b), and the catalyst is obtained by drying, and the drying temperature It is 90-230 ℃, and the drying time is 1-24 hours; calculated as oxide and based on catalyst, the amount of each component is such that the content of Group VIB metal com...

Embodiment 1

[0045] Using the gasoline raw material in Comparative Example 1, the gasoline raw material fractionation cutting and the light gasoline fraction alkali elution of mercaptan are the same as in Comparative Example 1.

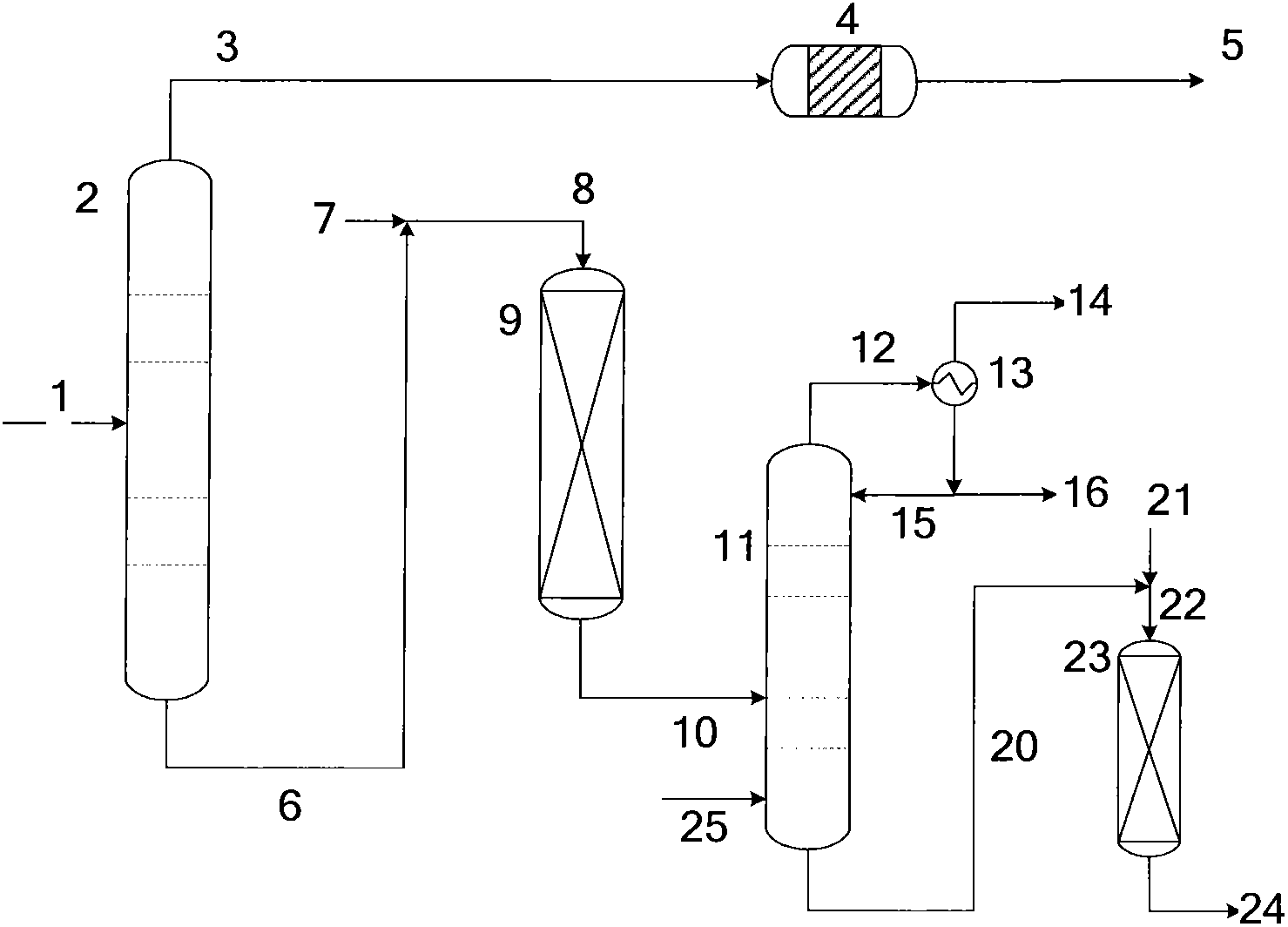

[0046] process such as figure 2 As shown, the heavy gasoline fraction obtained by cutting the gasoline raw material is subjected to two-stage hydrogenation, and the two-stage hydrogenation reactors are filled with RSDS-1 (produced by Sinopec Catalyst Changling Branch) catalyst. There is no reboiler at the bottom of the middle fractionation column, and H 2 Stripping, the C6-C7 fraction is distilled from the top of the tower. The hydrogenation process conditions and product properties are shown in Table 2. Intermediate Fractionator Stripping H 2 The volume ratio of feed heavy gasoline is 10-50Nm 3 / m 3 , its operating conditions and product properties are shown in Table 2. Mixing dehydrogenation of second-stage hydrogenation tail oil and intermediate fraction...

Embodiment 2

[0057] Using the gasoline raw material in Comparative Example 1, the gasoline raw material fractionation cutting and the light gasoline fraction alkali elution of mercaptan are the same as in Comparative Example 1.

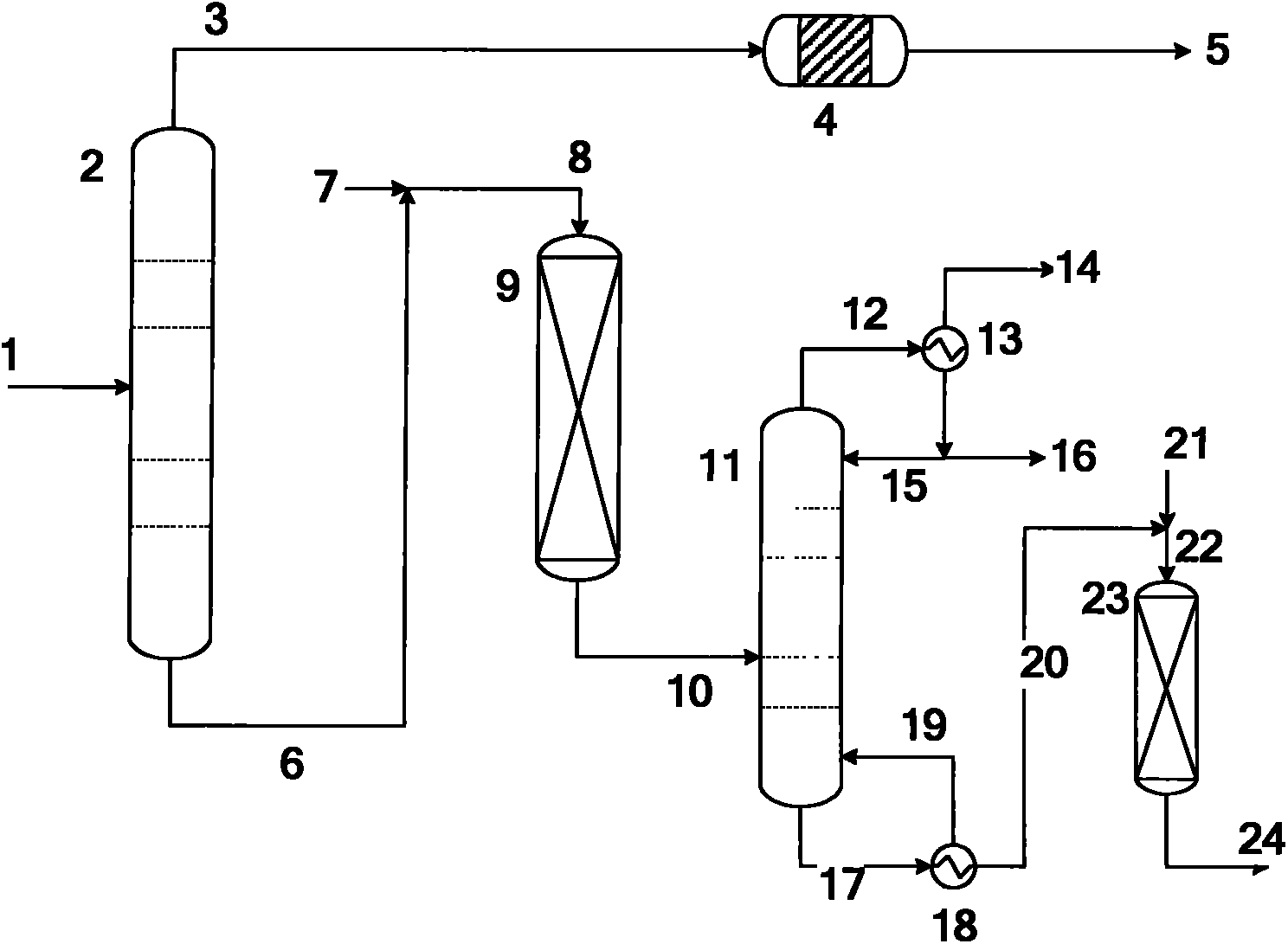

[0058] process such as figure 1As shown, the heavy gasoline fraction was subjected to two-stage hydrogenation, and the catalyst was the same as in Comparative Example 2. The middle fractionation column is heated by a bottom reboiler, and the C6-C7 fraction is distilled from the top of the column. The hydrogenation process conditions are shown in Table 2. The operating conditions and product properties of the middle fractionation tower are shown in Table 3. Mixing dehydrogenation of second-stage hydrogenation tail oil and intermediate fractionation overhead liquid phase product 2 The properties of the gasoline product obtained by blending S with the light fraction after alkali refining are listed in Table 5.

[0059] Compared with the comparative example, using...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com