A method of improving selectivity of a selective hydrodesulfurization catalyst

A hydrodesulfurization and selective technology, applied in the petroleum industry, treating hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problems of reducing the desulfurization activity of the catalyst, shortening the operation cycle of the device, and long processing time, so as to achieve easy implementation and high product quality. Low octane loss and low olefin saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

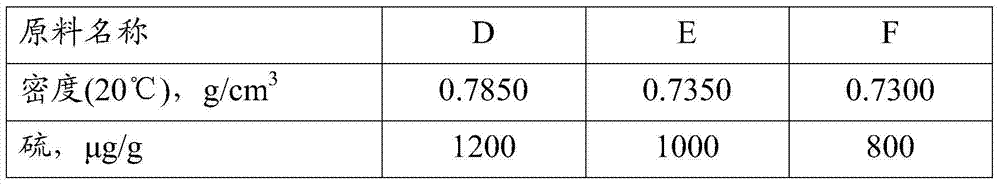

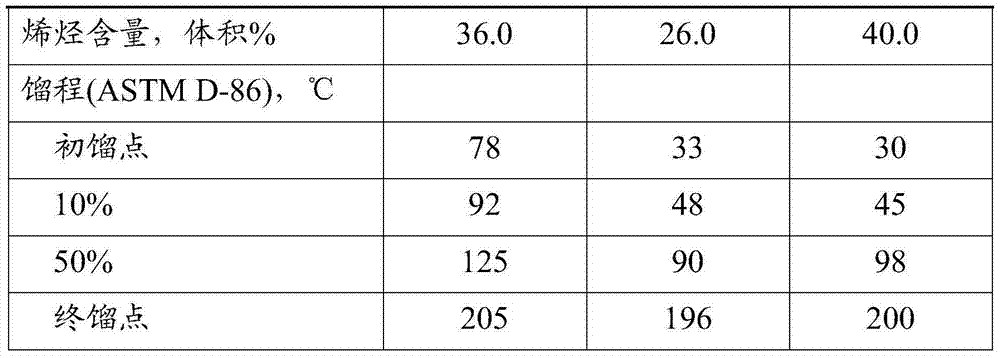

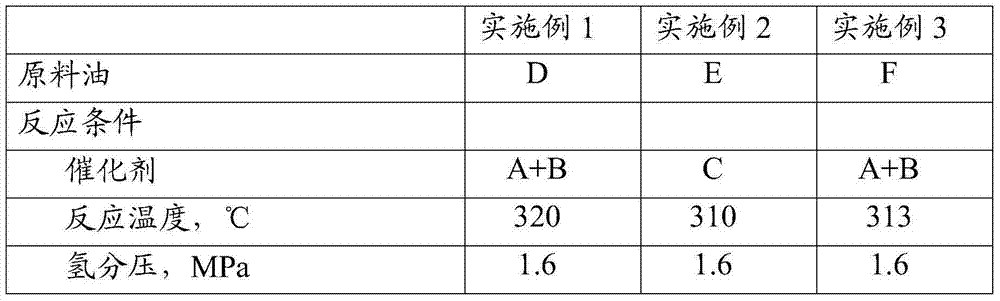

Embodiment 1

[0041] Using fresh A and B catalysts, the loading volume ratio of A and B catalysts in the reactor is A:B=85:15. The catalysts A and B in the reactor are vulcanized, and after the vulcanization finishes,

[0042] Adjust the gas in the reaction system to be a regulating gas. In the regulating gas, the volume fraction of hydrogen is 95%, and the volume fraction of the sum of hydrogen sulfide and carbon monoxide is 3%. The regulating raw materials are introduced into the reaction system, and the distillation range of the regulating raw materials is 30-200 ℃, where the volume fraction of olefins is 30%, the silicon content is 10μg / g, the volume fraction of aromatics is 18%, and the hydrogen partial pressure is 1.6MPa under the control conditions; the hydrogen-oil ratio is 400Nm 3 / m 3 ;Volume space velocity 4.0h -1 ; After contacting with the catalyst for 70 hours at a reaction temperature of 360°C.

[0043] Then adjust to normal reaction conditions, switch control raw material...

Embodiment 2

[0047] Using fresh C catalyst, the C catalyst in the reactor is vulcanized, after the vulcanization is finished,

[0048] The regulated raw materials are introduced into the reaction system, and under the regulated conditions, the hydrogen partial pressure is 1.6MPa; the hydrogen-oil ratio is 200Nm 3 / m 3 ;Volume space velocity 4.0h -1 Contacting the catalyst for 70 hours at a reaction temperature of 350° C., adjusting the distillation range of the raw material to 30-200° C., wherein the volume fraction of aromatics is 30%, and the silicon content is 50 μg / g.

[0049] Adjust the gas in the reaction system to be a regulating gas. In the regulating gas, the volume fraction of hydrogen is 95%, and the volume fraction of the sum of hydrogen sulfide and carbon monoxide is 0.3%. The regulating raw material is introduced into the reaction system, and the distillation range of the regulating raw material is 30-200 ℃, wherein the volume fraction of olefins is 25%, the silicon content...

Embodiment 3

[0054] Using fresh A and B catalysts, the loading volume ratio of A and B catalysts in the reactor is A:B=85:15. The catalysts A and B in the reactor are vulcanized, and after the vulcanization finishes,

[0055] Adjust the gas in the reaction system to be a regulating gas. In the regulating gas, the volume fraction of hydrogen is 95%, and the volume fraction of the sum of hydrogen sulfide and carbon monoxide is 1.5%. The regulating raw material is introduced into the reaction system, and the distillation range of the regulating raw material is 30-200 ℃, where the volume fraction of olefins is 30%, the silicon content is 3μg / g, the volume fraction of aromatics is 18%, and the hydrogen partial pressure is 1.6MPa under the control conditions; the hydrogen-oil ratio is 400Nm 3 / m 3 ;Volume space velocity 4.0h -1 ; After contacting with the catalyst for 70 hours at a reaction temperature of 360°C.

[0056] Adjust to normal reaction conditions, switch the control raw material to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com