Preparation method of attapulgite-based nano compound desulfurizer

A nano-composite, attapulgite technology, applied in chemical instruments and methods, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of gasoline octane loss, large equipment investment and operating costs, etc., to achieve inhibition of agglomeration, selectivity Tall, size-controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

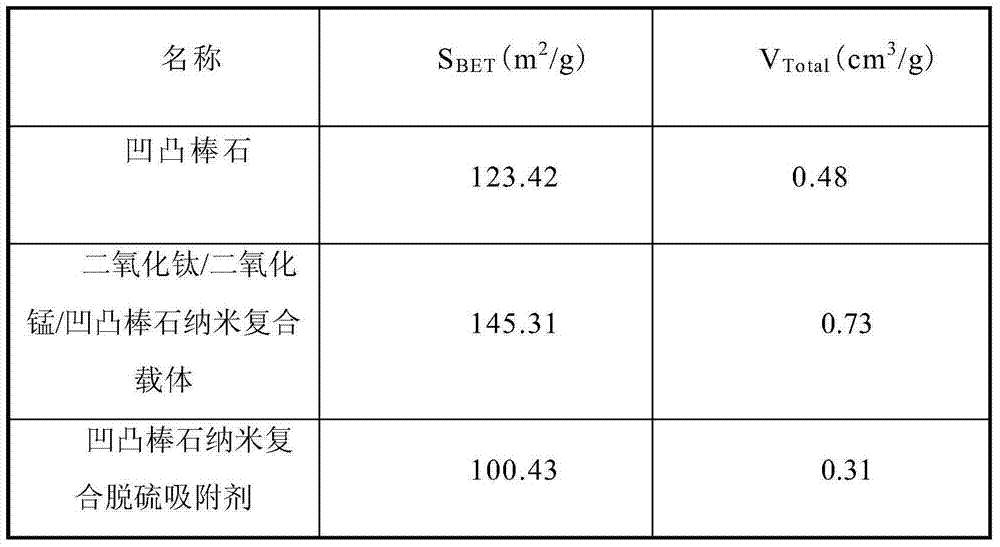

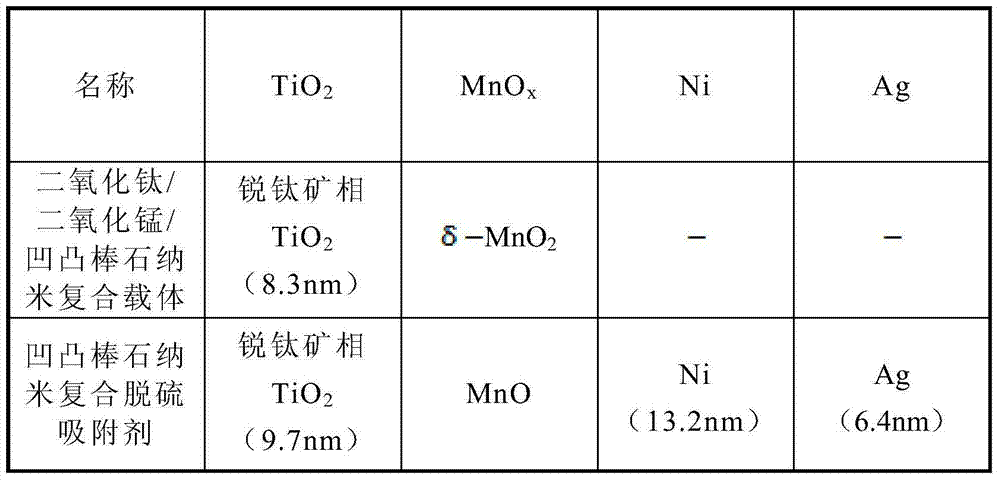

Embodiment 1

[0044] (1) Preparation of titanium dioxide / manganese dioxide / attapulgite nanocomposite carrier: according to the molar ratio of potassium permanganate and manganese sulfate as 2.5:1, take 33.4g potassium permanganate and add it to 160ml, 50g / L attapulgite rod In the stone clay slurry, mix evenly, then add 137.5ml of the mixed solution of titanium tetrachloride and manganese sulfate, the molar ratio of titanium tetrachloride and manganese sulfate is 1:6.1, and the concentration of titanium tetrachloride is 0.1mol / L, then warming up to 80°C while keeping the temperature for 2 hours, adding 0.5mol / L ammonium bicarbonate solution, adjusting pH=6, filtering, washing, and drying to obtain titanium dioxide / manganese dioxide / attapulgite nanocomposite carrier;

[0045] (2) Prepare attapulgite nano-composite desulfurization adsorbent precursor: nickel nitrate and silver nitrate are dissolved in 5ml deionized water according to the molar ratio of nickel and silver at 40:1, and stir evenl...

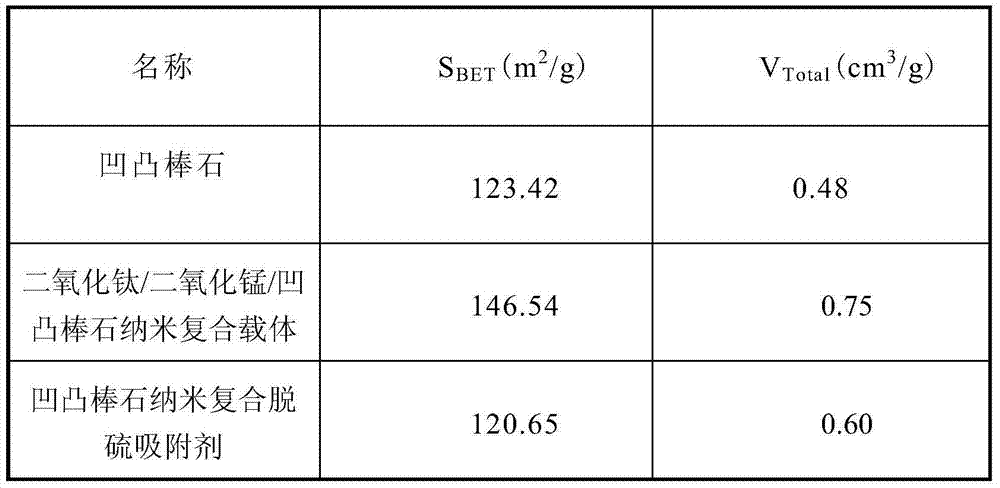

Embodiment 2

[0053] (1) Preparation of titanium dioxide / manganese dioxide / attapulgite nanocomposite carrier: according to the molar ratio of potassium permanganate and manganese sulfate as 2:1, take 34.8g potassium permanganate and add it to 67ml, 50g / L attapulgite rod In the stone clay slurry, mix evenly, then add 140.63ml of a mixed solution of titanium tetrachloride and manganese sulfate, the molar ratio of titanium tetrachloride and manganese sulfate is 1:10, and the concentration of titanium tetrachloride is 0.08mol / L, then heated up to 100°C and kept for 3h reaction, added 1.5mol / L potassium carbonate solution, adjusted pH=6.5, filtered, washed, dried to obtain titanium dioxide / manganese dioxide / attapulgite nanocomposite carrier.

[0054] (2) Prepare attapulgite nano-composite desulfurization adsorbent precursor: nickel nitrate and silver nitrate are dissolved in 5ml deionized water according to the molar ratio of nickel and silver at 20:1, and stir evenly; The total mass fraction o...

Embodiment 3

[0062] (1) Preparation of titanium dioxide / manganese dioxide / attapulgite nanocomposite carrier: according to the molar ratio of potassium permanganate and manganese sulfate as 5:1, take 108.75g potassium permanganate and add it to 40ml, 100g / L attapulgite rod In the stone clay slurry, mix evenly, then add 100ml of the mixed solution of titanium tetrachloride and manganese sulfate, the molar ratio of titanium tetrachloride and manganese sulfate is 1:28.2, and the concentration of titanium tetrachloride is 0.05mol / L , and then heated up to 150° C. for 5 hours of heat preservation, added 3 mol / L ammonia solution, adjusted to pH=7.5, filtered, washed, and dried to obtain a titanium dioxide / manganese dioxide / attapulgite nanocomposite carrier.

[0063] (2) Prepare attapulgite nano-composite desulfurization adsorbent precursor: nickel nitrate and silver nitrate are dissolved in 5ml deionized water according to the molar ratio of nickel and silver at 10:1, and stir evenly; The total m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com