High-temperature high-pressure gas reservoir permeability flow velocity sensitivity test method considering bound water

A technique for measuring permeability and high-pressure gas by gas, which is applied in the fields of permeability/surface area analysis, measuring device, suspension and porous material analysis, etc., and can solve problems such as unconsidered, unconcerned influence of irreducible water, large formation pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, the present invention will be further explained based on the accompanying drawings, so that those skilled in the art can understand the present invention. However, it should be clear that the present invention is not limited to the scope of the specific embodiments. For those of ordinary skill in the art, as long as various changes fall within the spirit and scope of the present invention defined and determined by the appended claims, they are all protected. Column.

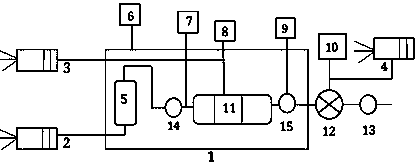

[0046] See figure 1 .

[0047] The permeability and flow velocity sensitivity test method of high-temperature and high-pressure gas reservoirs considering irreducible water is completed by a gas permeability measurement device, which consists of a thermostat 1, a core holder 11, a displacement pump 2, a confining pressure pump 3, and a back pressure pump 4. The intermediate container 5 containing the test gas is composed. The inlet end of the core holder 11 is connected to the intermediate contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com