Method for roasting cement clinker through sulphur coal by dry-process rotary kiln

A technology of dry rotary kiln and cement clinker, applied in the field of cement production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following is the concrete improvement and analysis of the inventive method:

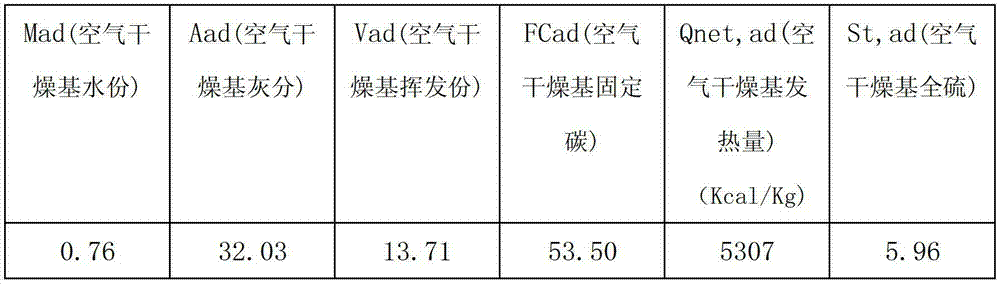

[0013] 1, the present invention uses industrial analysis and ash content of high-sulfur coal:

[0014] Industrial analysis and total sulfur content of high sulfur coal:

[0015]

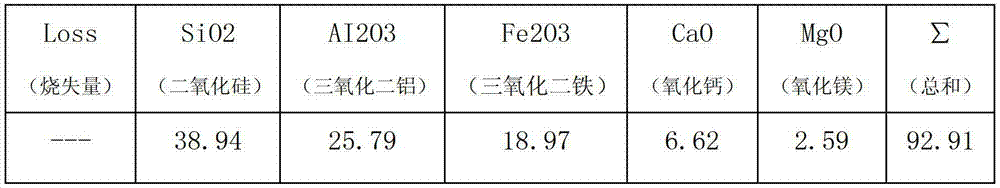

[0016] Analysis of coal ash chemical composition:

[0017]

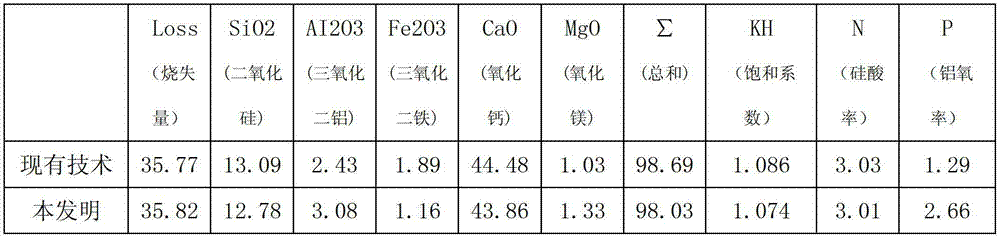

[0018] 2. Improvement of batching scheme of the present invention

[0019] Generally, the harmful components such as alkali and chlorine in the cement raw materials used in the production plant are relatively high. The alkali content in the clinker is 1.0-1.5%, the chlorine content is about 0.05%, the SO3 content is between 2.5-3.5%, and the sulfur-alkali ratio is 1.0. Between -1.40. In order to be able to adapt to burning high-sulfur coal, we need to adjust the raw material ingredients, using the ingredients with medium saturation ratio, medium-low silicic acid rate, and high alumina rate: KH: 0.90±0.02, N: 2.5±0.1, P : 2.0±0.1. In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com