Preparation method of low-heat-consumption low-silicon-rate and high-strength silicate cement clinker

A technology of Portland cement and low heat consumption, which is applied in the field of cement manufacturing, and can solve the problems that clinker 28d strength advantages cannot be exerted, the qualified rate of f-CaO is low, and clinker is difficult to calcine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

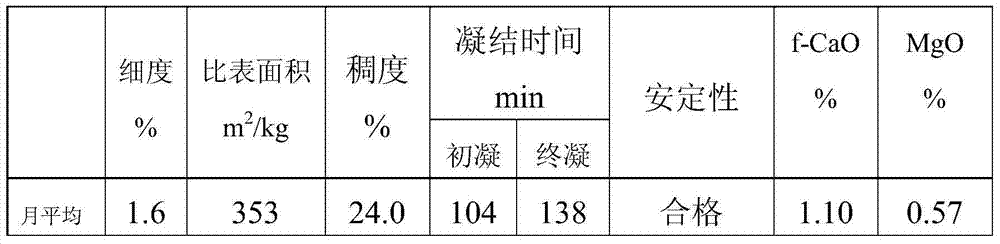

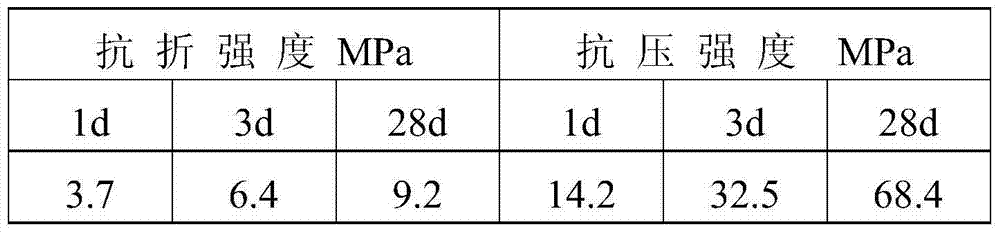

Examples

Embodiment

[0032] A method for preparing Portland cement clinker with low energy consumption, low silicon rate and high strength, specifically comprising the following steps:

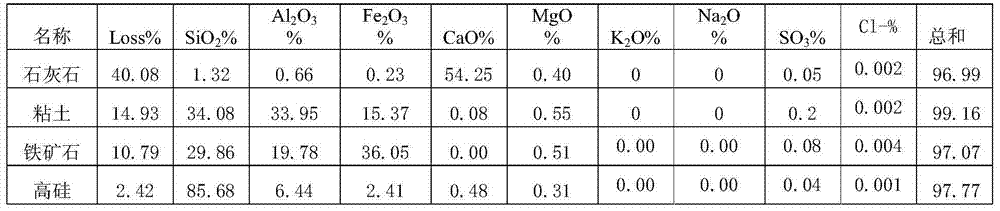

[0033] 1) Calculation of ingredients: The Portland cement clinker uses limestone, clay, iron ore, and high silicon as raw materials. The chemical composition of each raw material is analyzed as follows:

[0034]

[0035] The chemical analysis of the mineral content of the designed raw meal / clinker is as follows:

[0036] name

Loss%

SiO 2 %

Al 2 o 3 %

Fe 2 o 3 %

CaO%

MgO%

K 2 O%

Na 2 O%

SO 3 %

Cl-%

the sum

33.70

12.87

3.73

2.73

43.70

0.40

0.00

0.00

0.06

0.002

97.18

clinker

0

20.37

6.27

4.18

64.28

0.61

0.00

0.00

0.12

0.003

95.83

[0037] The ratio of each raw material is:

[0038] limestone

clay

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com