A preparation method of Portland cement clinker with low heat consumption, low silicon rate and high strength

A Portland cement, low heat consumption technology, applied in the field of cement manufacturing, can solve the problems of reduced liquid phase, high clinker consumption, poor clinker granulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] A method for preparing Portland cement clinker with low energy consumption, low silicon rate and high strength, specifically comprising the following steps:

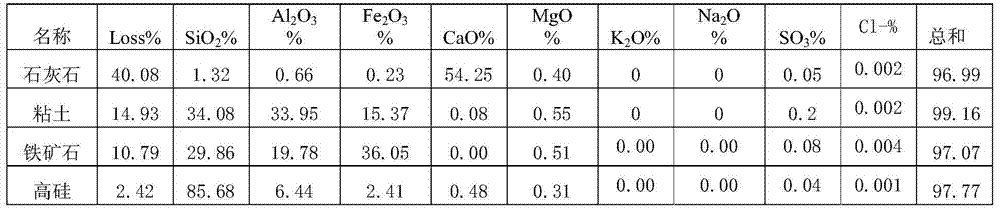

[0033] 1) Calculation of ingredients: The Portland cement clinker uses limestone, clay, iron ore, and high silicon as raw materials. The chemical composition of each raw material is analyzed as follows:

[0034]

[0035] The chemical analysis of the mineral content of the designed raw meal / clinker is as follows:

[0036] name Loss% SiO 2 %

Al 2 o 3 %

Fe 2 o 3 %

CaO% MgO% K 2 O%

Na 2 O%

SO 3 %

Cl-% sum Raw material 33.70 12.87 3.73 2.73 43.70 0.40 0.00 0.00 0.06 0.002 97.18 Clinker 0 20.37 6.27 4.18 64.28 0.61 0.00 0.00 0.12 0.003 95.83

[0037] The ratio of each raw material is:

[0038] limestone clay iron ore high silicon 80.45% 4.99% 4.24% 10.32%

[0039] The designed clinker ratio and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com