Testing device for anisotropism of shale in true-triaxial condition and testing method of testing device

A technology of anisotropy and testing equipment, applied in the field of petroleum exploration, can solve the problems of high brittleness of shale, difficulty in obtaining rock samples, difficulty in carrying out experiments, etc., and achieve the effect of simple sample preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

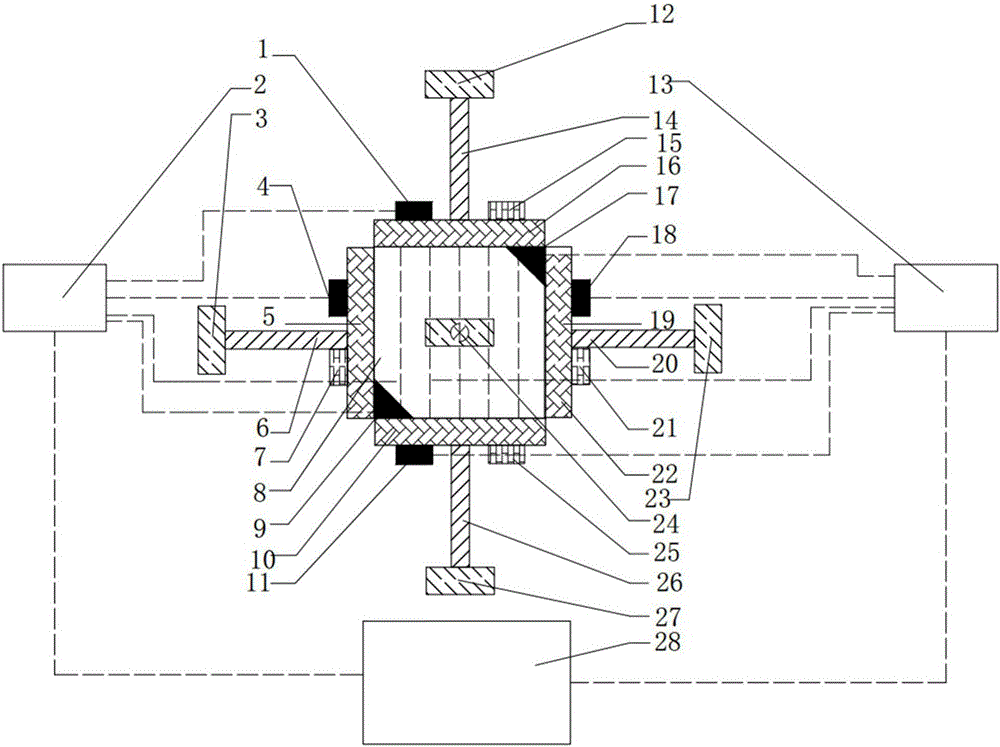

[0040]This embodiment is used for the shale anisotropy testing device under true triaxial conditions, and the shale is in a cubic structure, including:

[0041] Simulate the minimum horizontal principal stress, maximum horizontal principal stress, and vertical stress under the formation conditions along the XYZ three directions to pressurize the test shale;

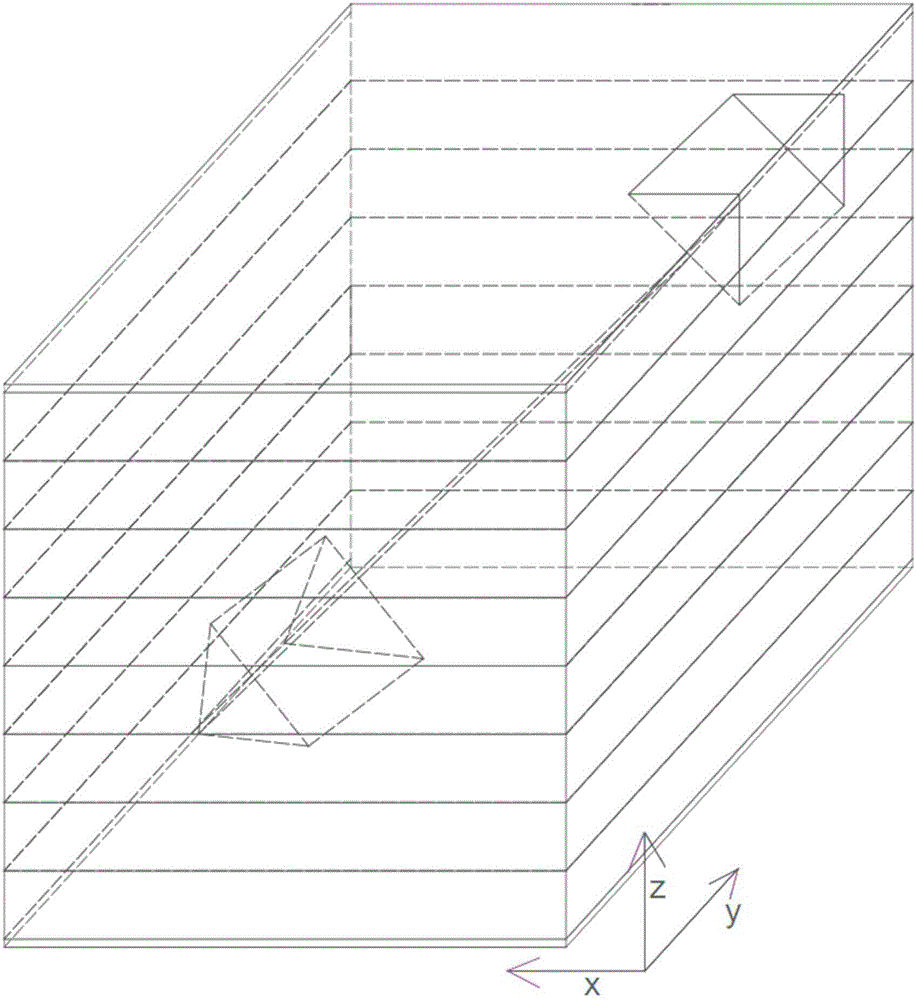

[0042] One acoustic wave lead block and one resistivity lead block are respectively arranged on two opposite surfaces forming 0° to the shale formation, and two opposite surfaces forming 90° to the shale formation An acoustic wave lead block and a resistivity lead block respectively arranged respectively, and a set of acoustic wave lead blocks respectively arranged on two opposite edges which are 45° to the shale layer, and each described acoustic wave lead block The acoustic wave emitter connected to the lead base by a wire, and the electric bridge instrument connected to each resistivity lead base by a wire; the acousti...

Embodiment 2

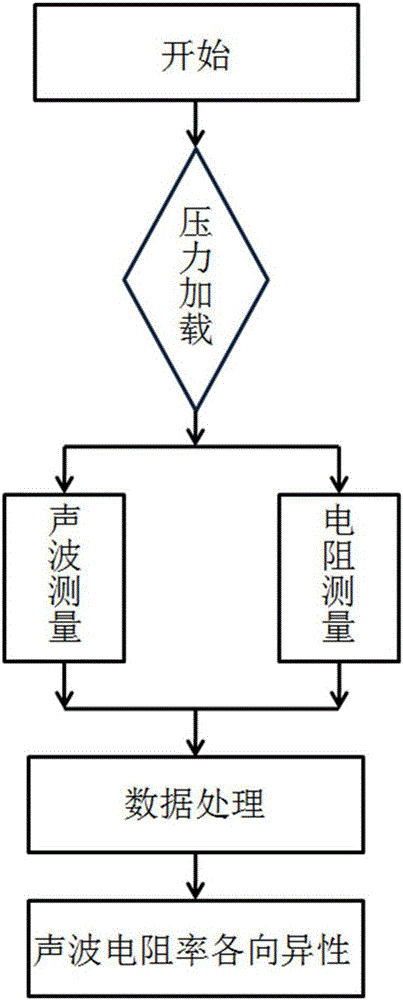

[0059] This embodiment is used for the testing method of the shale anisotropy testing device under the true triaxial condition, and the described testing device is the shale anisotropic testing device under the true triaxial condition described in the above embodiment, and the The test methods described include:

[0060] A shale formation rock sample is selected, and the shale formation rock sample is a cubic rock sample with a length, width, and height of 6 cm. machining wedge-shaped grooves on the diagonal edges of said shale;

[0061] The pressurizing mechanism first applies pressure along the X-axis; secondly, after the pressure is stable, the pressurizing mechanism applies pressure along the Z-axis; finally, the pressurizing mechanism applies pressure along the Y-axis; after the pressurizing mechanism is loaded, stabilize for 30 minutes;

[0062] First, the sound wave propagates along the direction of the vertical bedding shale, and at the same time the waveform is displ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com