Method for efficiently separating low-ore grade and complicated iron ore

A low-grade and complex technology, applied in the field of iron and steel metallurgy, can solve the problems of poor selectivity, poor sorting effect, and high cost, and achieve the effects of reducing production costs, reducing processing capacity, and improving iron grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

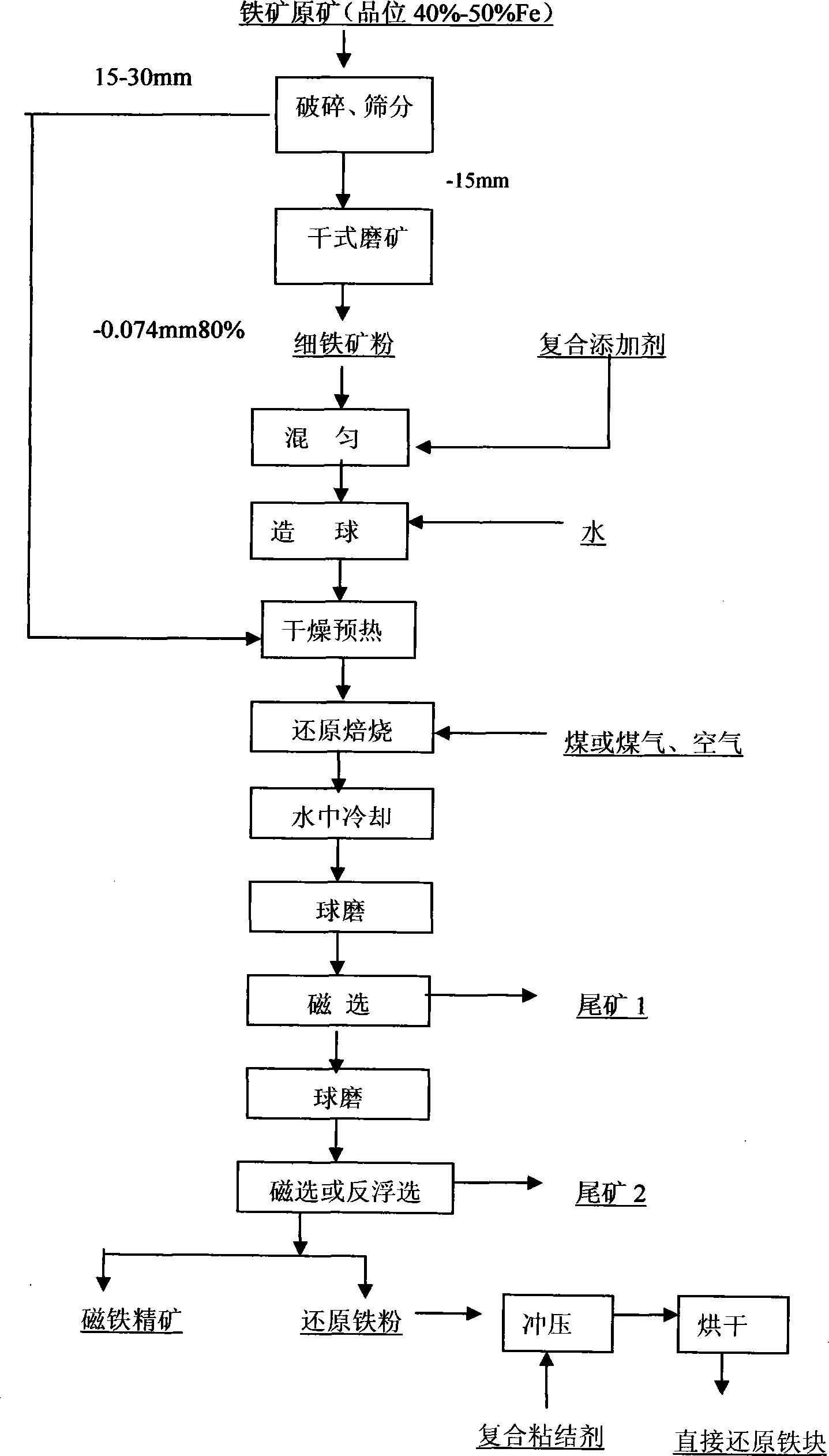

[0049] see image 3 , for limonite raw ore with an iron grade of 40.2%, after crushing and screening, the -15mm particle size is passed through a high-pressure roller mill to dry-grind to a fineness of 90%-200 mesh, with 4% compound Additives (sodium humate 1%, -200 mesh bituminous coal 3%), the mixture is mixed and pelletized in a disc pelletizer, pelletizing water is 10-12%, pelletizing time is 10min, and the particle size of raw pellets is 8 —20mm. Green pellet drying temperature is 260°C, drying time is 8min, preheating temperature is 550°C, preheating time is 6min, reduction roasting temperature is 800°C, roasting time is 15min, the proportion of bituminous coal is 280-350kg / t ore, and the roasted product is directly put into water for cooling Crushing magnetic separation. For the lump ore with particle size of 15-35mm, it is directly added to the chain grate machine for drying and preheating, reduction roasting in the rotary kiln, cooling in water, ball mill grinding, ...

Embodiment 2

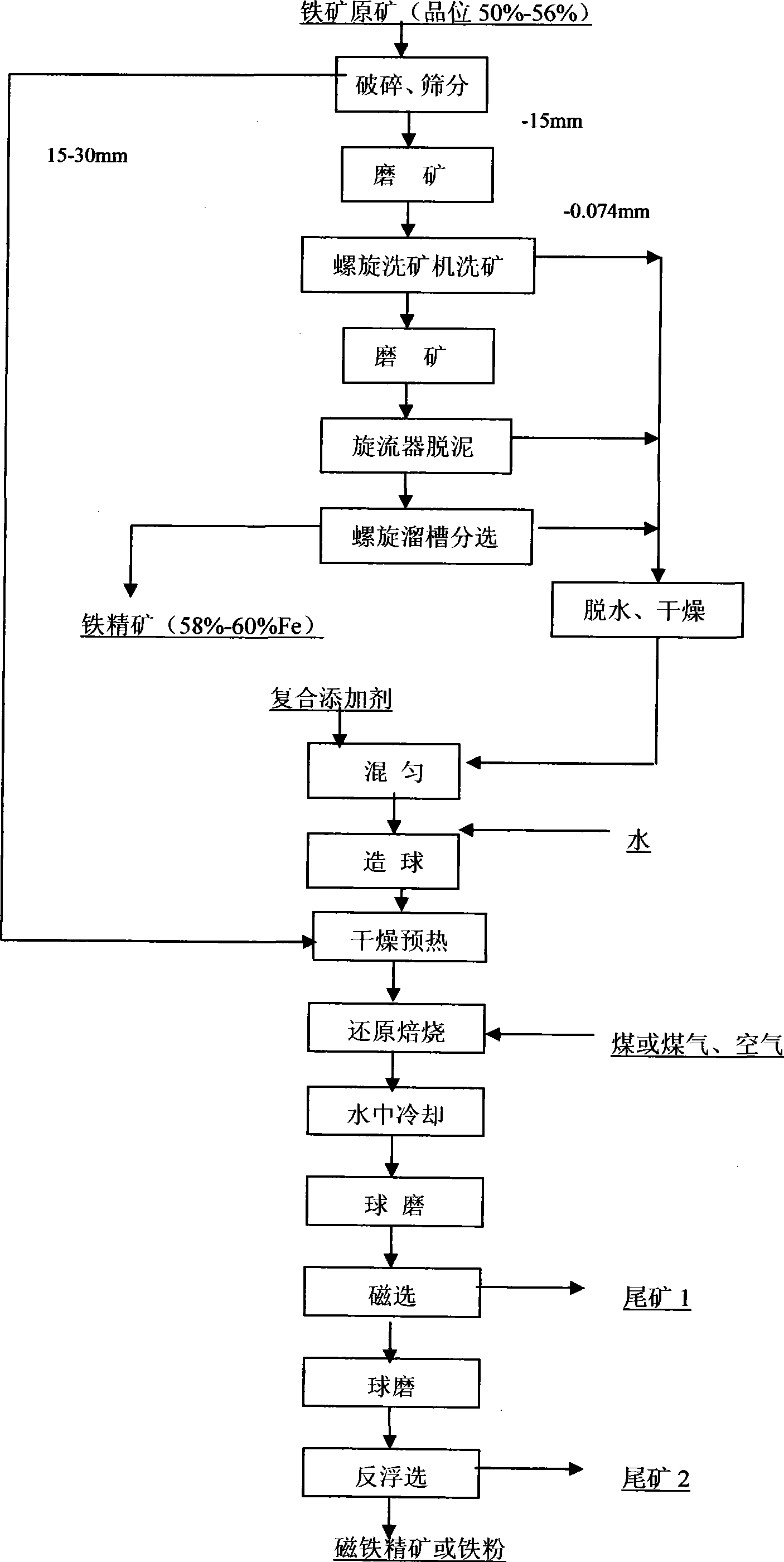

[0051] see figure 1 , for the limonite with an iron grade of 50.3%, after crushing and screening, the -15mm particle size is ground to -1.0mm, and then the ore is washed and deslimed by a spiral washing machine, and the -0.074mm particle size is removed. The +0.074mm particle size enters the second stage of grinding to -0.59mm, and the grinding product is washed and deslimed by a spiral washing machine to remove the -0.074mm particle size, and the coarse particle size is sorted by a spiral chute to produce iron Iron ore concentrate powder with a grade of 58-60%. All deslimed products (-0.074mm particle size) are combined, dehydrated, dried and ground to a fineness of 89.5%-200 mesh through a high-pressure roller mill, with 4.5% compound additives (sodium humate 1.5%, bituminous coal 3%), the mixture is mixed and pelletized in a disc pelletizer, the pelletizing water is 10-12%, the pelletizing time is 10min, and the pellet size is 8-20mm. Green pellet drying temperature is 26...

Embodiment 3

[0053] see figure 1 , for the limonite with an iron grade of 55.8%, after crushing and screening, the -15mm particle size is ground to -1.0mm, and then the ore is washed and deslimed by a spiral washing machine to remove the -0.074mm particle size, + The 0.074mm particle size enters the second stage of grinding to -0.59mm, and the grinding products are washed and deslimed by a spiral washing machine to remove the -0.074mm particle size, and the coarse particle size is sorted by a spiral chute to produce iron grades It is 58-60% iron concentrate powder. All deslimed products (-0.074mm particle size) are combined, dehydrated, dried and ground to a fineness of 90.8%-200 mesh (-0.074mm) through a ball mill, and added 5% of compound additives (sodium humate 2% , Bituminous coal 3%), the mixture is mixed and pelletized in a disc pelletizer, the pelletizing water is 10-12%, the pelletizing time is 10min, and the pellet size is 8-20mm. Green pellet drying temperature is 260°C, dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com