Method for selecting iron ore from red mud

A technology for iron ore and red mud, applied in the field of silicate, can solve the problems of poor industrial application feasibility, and achieve the effects of improving market competitiveness, high yield, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

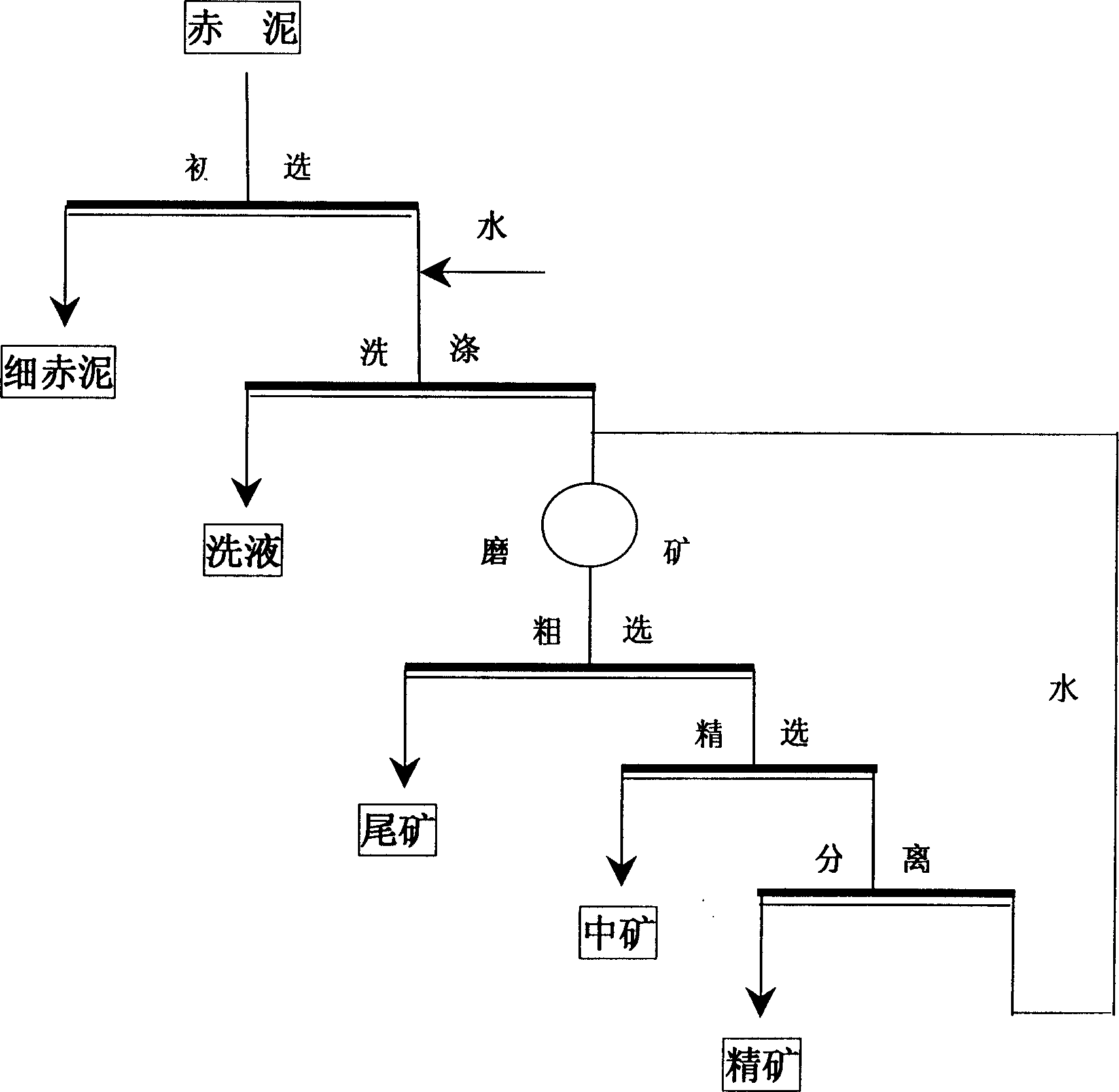

Image

Examples

Embodiment 1

[0015] The weight percent of red mud composition used in the present invention is composed of:

[0016] SiO 2 20.55, Fe 2 o 3 36.97, Al 2 o 3 20.46, Na 2 O 11.36. The balance is other. Among them, A / S (Al / Si ratio) was 1.00, and N / S (Na / Si ratio) was 0.55.

[0017] After primary selection, the weight percent of the selected red mud sand is composed of:

[0018] SiO 2 14.83, T Fe (total amount of Fe) 46.87, Al 2 o 3 6.54, CaO 0.43, MgO 0.16, and the balance is other. Among them, the S element is 0.028, and the P element is 0.255.

[0019] The weight percentage of ore sand phase is composed of: N 2 O·Al 2 o 3 1.68 SiO2 2 1.73H 2 O (hydrous sodium aluminosilicate) accounted for 22.4%; 3NaAlSiO 4 NaOH accounted for 3.4%; Fe 2 o 3 Accounted for 68.6%; AlO (OH) (a diaspore) accounted for 2.5%; CaCO 3 Accounting for 1.42%.

[0020] The main minerals in ore are hematite, goethite, siderite, hydrous sodium aluminosilicate, diaspore, followed by aragonite and c...

Embodiment 2

[0028] The method for selecting iron ore from red mud according to the present invention is as follows:

[0029] The fine red mud is removed from the red mud to obtain red mud sand, and the red mud sand is separated and washed twice to obtain red mud sand; the red mud sand is ground and graded, and the fineness is controlled to pass through a 200 mesh sieve to account for 60%. Separation, the operating pressure is controlled at 0.20Mpa, roughing and beneficiation are carried out, the tailings are removed by roughing to obtain middle ore, and the concentrate is obtained by beneficiation. The process conditions of pulsating high-gradient magnetic separation control are as follows:

[0030] Rough selection part: background field strength and magnetic flux density 0.92T, pulse frequency 140 times / min, flow rate 100L / H, feeding time 3 minutes;

[0031] Selected part: background field strength and magnetic flux density 0.75T, pulse frequency 220 times / min, flow rate 100L / H, mine fee...

Embodiment 3

[0035] The method for selecting iron ore from red mud according to the present invention is as follows:

[0036] The fine red mud is removed from the red mud to obtain red mud sand, and the red mud sand is separated and washed twice to obtain red mud sand; the red mud sand is ground and graded, and the fineness is controlled to pass through a 200 mesh sieve to account for 65%, and the graded cyclone is used to obtain the red mud sand. Separation, the operating pressure is controlled at 0.24Mpa, roughing and beneficiation are carried out, the tailings are removed by roughing to obtain middle ore, and the concentrate is obtained by beneficiation. The process conditions of pulsating high-gradient magnetic separation control are as follows:

[0037] Rough selection part: background field strength and magnetic flux density 0.90T, pulse frequency 120 times / min, flow rate 110L / H, feeding time 3 minutes;

[0038] Selected part: background field strength and magnetic flux density 0.80T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com