Desulfuration method for high sulfide pyrite powder

A technology of iron ore powder and high sulfur, applied in chemical instruments and methods, improvement of process efficiency, flotation, etc., to achieve low cost, high benefit, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

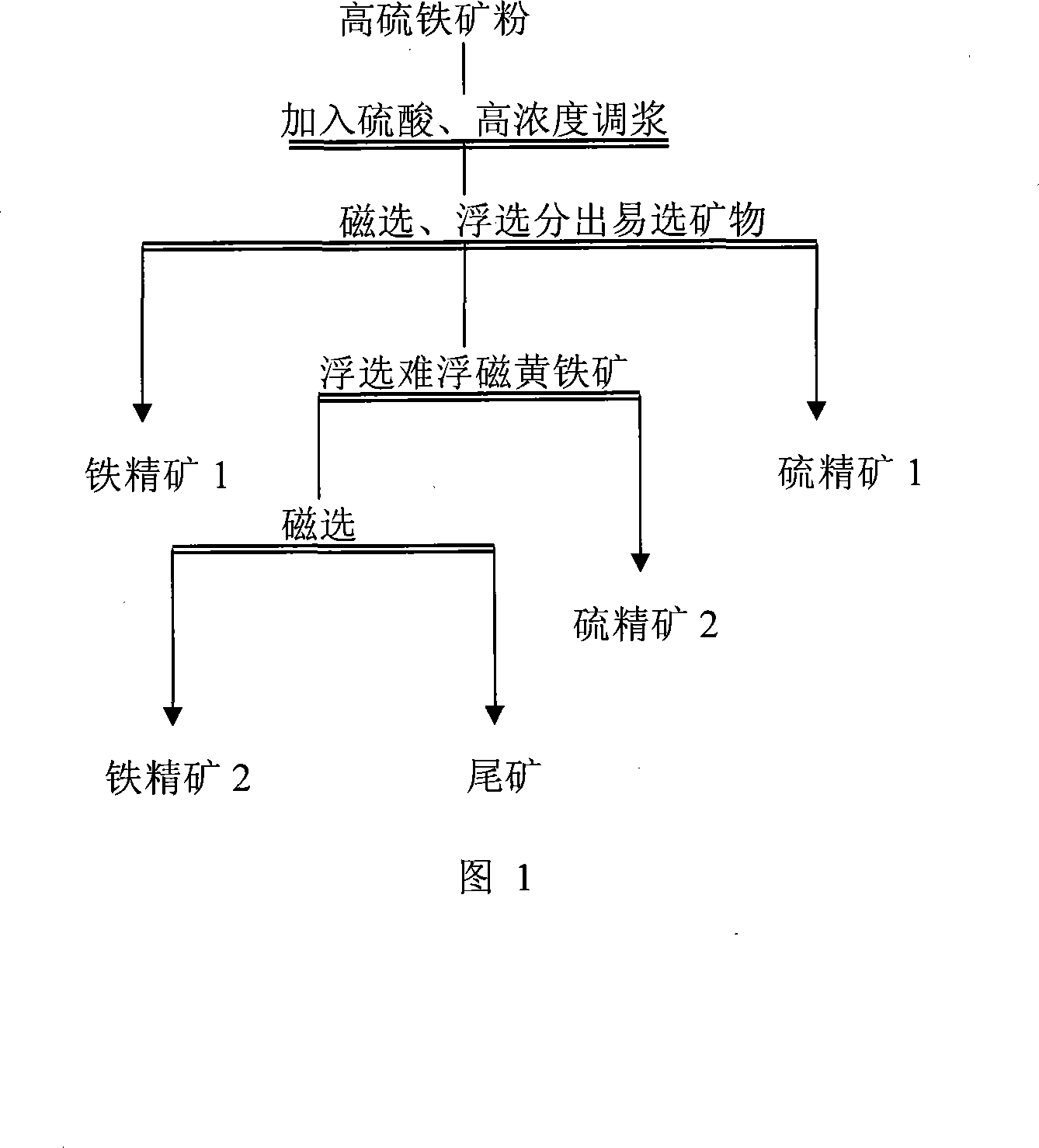

[0011] Example: The beneficiation tailings of a certain lead-zinc ore contain magnetite and a large amount of suppressed pyrrhotite. Through weak magnetic separation, a mixed concentrate of magnetite and pyrrhotite is obtained. The concentrate contains iron It is 57.13%, while the sulfur content is as high as 16.28%. Add 750g / t of sulfuric acid at a concentration of 50% of the pulp, adjust the pulp for 5 minutes, then add 50g / t of butyl xanthate and 30g / t of 2# oil, and float out easily sulfide minerals, namely sulfur concentrate 1; Under the condition of a magnetic field strength of 500 Oersted, the magnetite concentrate 1 was obtained; the magnetic separation tailings were added with humic acid 2000g / t to disperse the pulp, and then added 100g / t butyl xanthate and 50g / t 2# oil, the flotation was difficult Float the pyrrhotite to get the second sulfur concentrate, and then enter the magnetic separation with the flotation tailings. The magnetic field strength is 1000 Oersted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com