Low-grade magnetite pre-selection and waste abandoning mineral separation process

A low-grade magnetite technology, applied in grain processing, etc., can solve problems such as large ore particle size, difficulty in achieving satisfactory throwing effect, and insufficient ore dissociation degree, so as to improve the grinding grade, expand resource utilization, The effect of reducing the amount of ore entering the grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

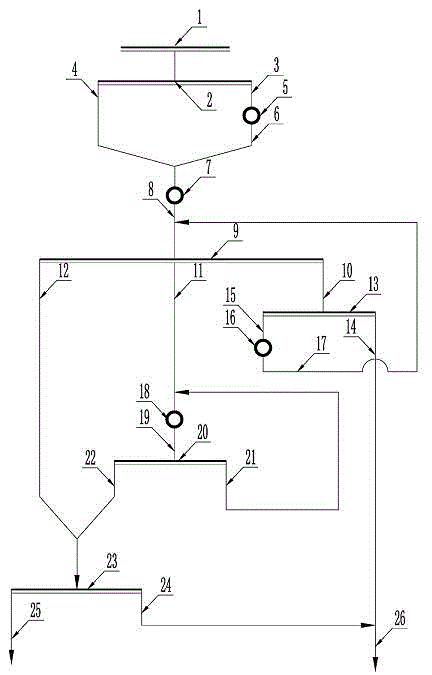

[0031] Example: Such as figure 1 As shown, according to a kind of low-grade magnetite preselection of the present invention throwing waste beneficiation process is realized in this way, the iron ore raw ore 1 that the stope is transported to the raw ore warehouse of the dressing plant is divided into the over-sieve block through the bar feeder 2 Ore 3 and fine ore under sieve 4; lump ore on sieve 3 is subjected to coarse crushing 5 to obtain product A6; fine ore under sieve and product A6 are combined to be crushed 7 to obtain product B8; product B8 and finely crushed product C17 are fed together The first section of screening 9 screens out the first section of the sieve product 10, the first section of the sieve product 11 and the first section of the underscreen product 12; the first section of the sieve product 10 is fed into the magnetic pulley for the first section of preselection throw Waste 13, the first section of preselected tailings 14 and the first section of pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com