Method and device for fixing automotive wiring harness and washing pipe

A technology of automobile wiring harness and fixing method, which is applied to vehicle components, transportation and packaging, circuits or fluid pipelines, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

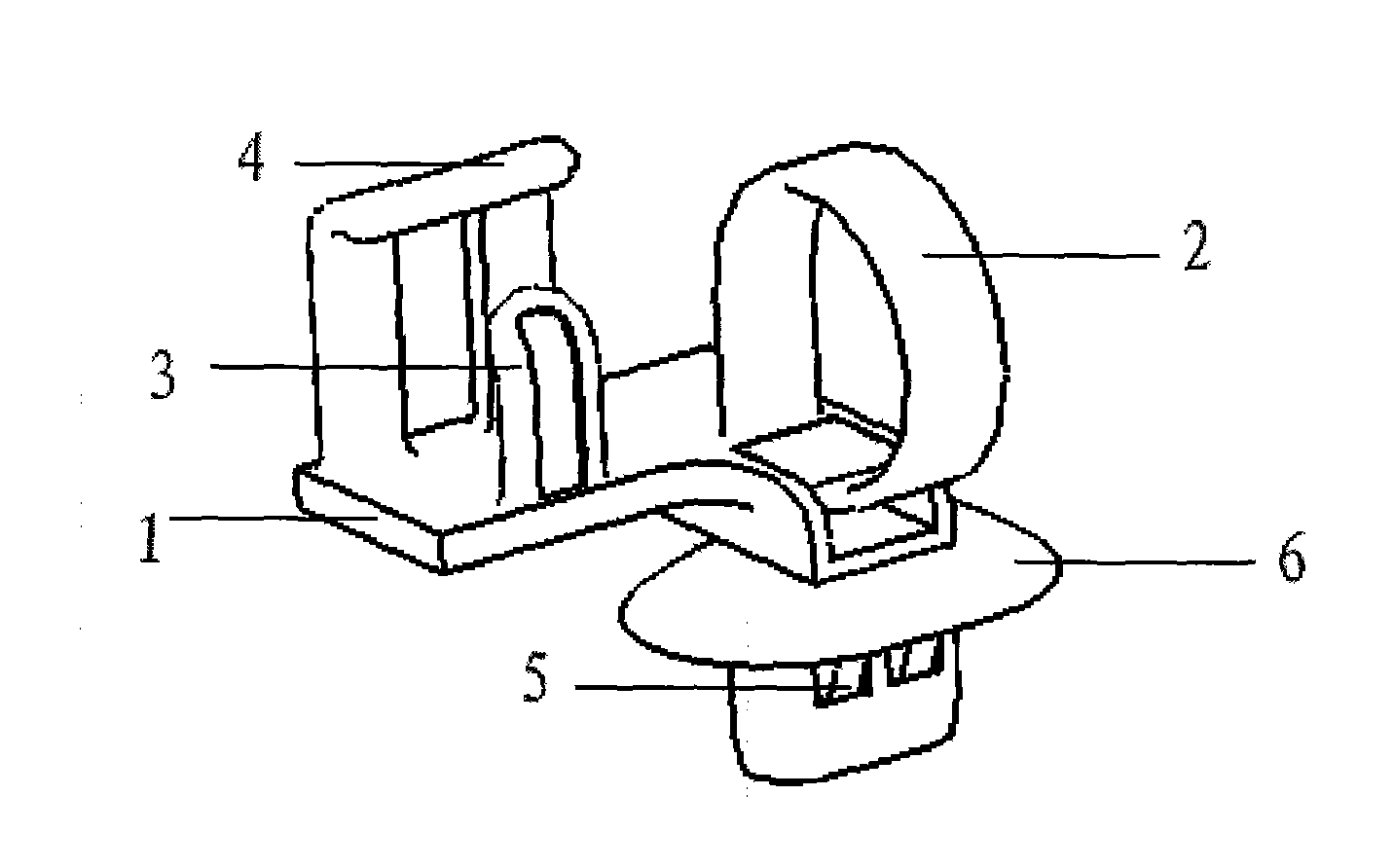

[0024] Such as figure 1 As shown, the body of the fixing bracket is a flat plate 1, on which a wire harness strap 2 is arranged; on the flat plate, a washing pipe fixing clip 3 is arranged, and a carpet hook 4 is also arranged on the flat plate. The lower part of the plate is provided with a buckle 5 for fixing with the automobile sheet metal, and the lower part of the plate is provided with a skirt structure 6 matched with the buckle.

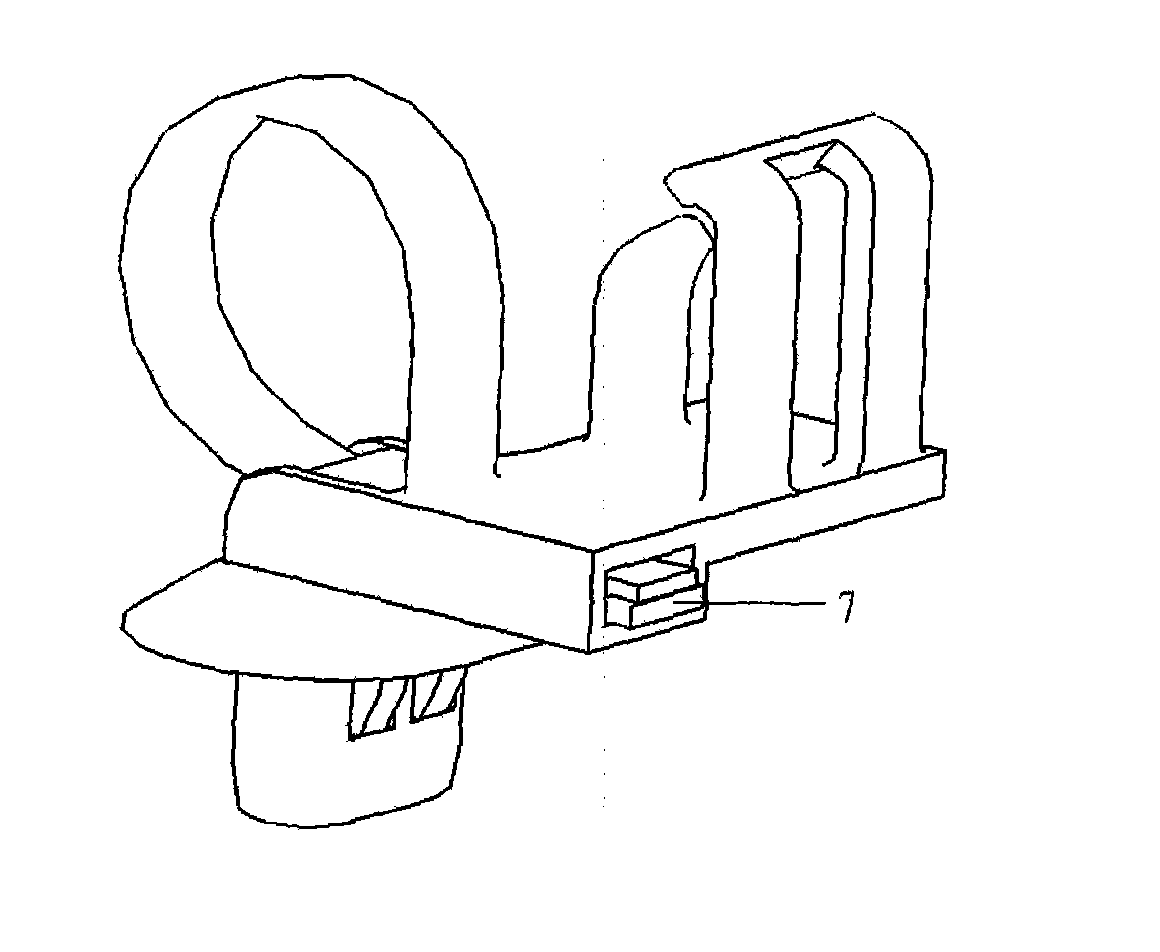

[0025] Such as figure 2 As shown, the harness strap has a release mechanism 7.

[0026] When you need to install:

[0027] Fix the wire harness and the bracket with the wire harness strap 2. After tightening the strap, cut off the excess part.

[0028] Use the washing tube fixing clip 3 on the plate to fix the washing tube and the bracket.

[0029] Utilize the carpet hook 4 on the flat panel to fix the carpet with the support.

[0030] Utilize the guiding mechanism of the buckle, insert the buckle 5 into the sheet metal hole. The skirt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com