Purification method for hydrogen sulfide containing gas

A hydrogen sulfide and gas technology, applied in the field of hydrogen sulfide purification and hydrogen sulfide purification in the exhaust gas discharged from refineries, can solve the problems of secondary pollution, complex process flow, blockage of process equipment, etc., to prevent fog entrainment, simple equipment, The effect of energy saving and consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

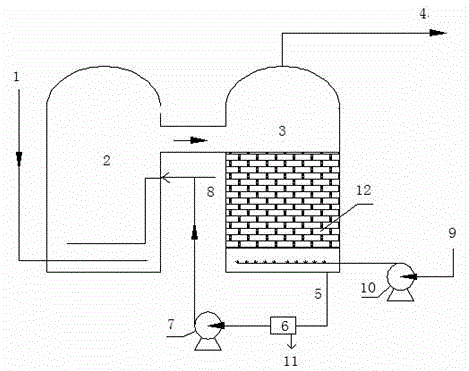

[0035] This embodiment adopts image 3 As shown in the process flow, the hydrogen sulfide content in the waste gas is 8000~10000mg / m 3 , gas volume is 500m 3 / h, the exhaust gas temperature is normal temperature, the pressure is slightly positive pressure, the absorption reactor 2 adopts a bubbling absorption structure, the height of the bubbling bed is 2.5m, and the absorbent is MDEA solution. The regeneration reactor 3 is a suspension bed reactor, the height of the suspension bed is 3m, and the regeneration agent is ferric oxyhydroxide, which has a honeycomb structure, and the pore diameter of the honeycomb is 8mm. In the regeneration reactor, the regenerant is packed in three layers. The flow direction of the liquid and the regeneration air in the regeneration reactor 3 is reverse flow, the liquid flows from the top to the bottom, and the flow velocity of the liquid is 1.5m / s. Sulfur powder filter set three, switching operation. After the exhaust gas is absorbed and pur...

Embodiment 2

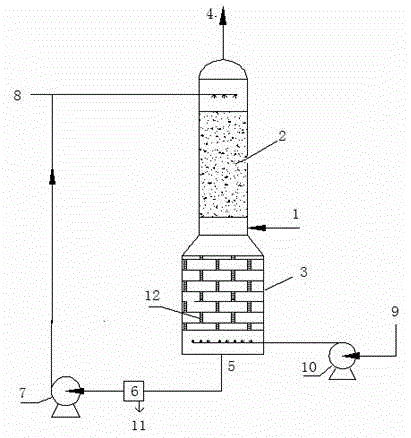

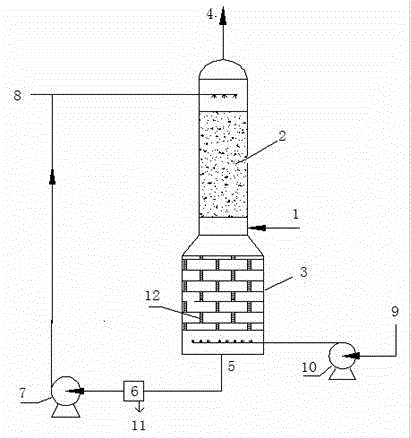

[0037] This embodiment adopts figure 1 As shown in the process flow, the hydrogen sulfide content in the exhaust gas is 7000~8000mg / m 3 , gas volume is 300m 3 / h, the exhaust gas temperature is normal temperature, the pressure is slightly positive pressure, the absorption section 2 adopts packing absorption structure, adopts φ25mm saddle ring packing, packing height is 4m, and the absorbent is MDEA solution. The regeneration section is a suspended bed reactor with a suspension bed height of 3m. The desulfurization regeneration agent in the regeneration reaction section 3 is iron oxyhydroxide with a honeycomb structure. The pore diameter of the honeycomb is 10mm, and the regeneration agent is packed in 3 layers. The flow direction of the liquid and the regeneration air in the regeneration reactor 3 is reverse flow, the liquid flows from the top to the bottom, and the flow velocity of the liquid is 1.5m / s. Sulfur powder filter set three, switching operation. After the exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com