Multi-purpose fastening bracket and mounting method thereof

A technology for fastening brackets and bracket clips, applied in the direction of electrical components, etc., can solve problems such as damage to wiring harnesses, blockage of washing water pipes, and affecting the clearance of peripheral parts installed in wiring harnesses, so as to achieve the effect of protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

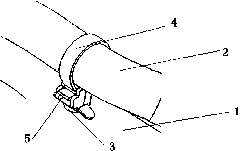

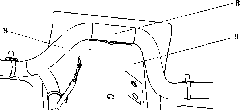

[0073] 1. On the sheet metal (1) where the wire harness needs to be fixed, select a suitable sheet metal surface to open a sheet metal hole (3), the diameter of the fixing hole is 6.2mm×12.2mm (according to the body fastening structure that comes with the cable tie Adjust the size, 0.2mm positive tolerance);

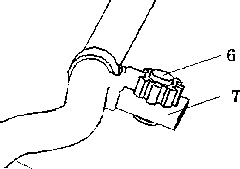

[0074] 2. Utilize the sheet metal hole introduction structure introduction mechanism (26) of the clamping structure of the enhanced multi-purpose fastening bracket sheet metal fixing structure (21), to facilitate the insertion of the enhanced multi-purpose fastening bracket sheet metal fixing structure (21) into the sheet metal hole (3);

[0075] 3. The enhanced multi-purpose fastening bracket sheet metal fixed structure clamping structure and the sheet metal clamping surface (25)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com