Active carbon fiber-based industrial flue gas desulfurization and denitrification device and method

An activated carbon fiber, desulfurization and denitrification technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems affecting the service life of activated carbon, low oxidation process efficiency, dry process regeneration, etc., to achieve good environmental benefits and Social benefits, avoidance of energy consumption and blockages, low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

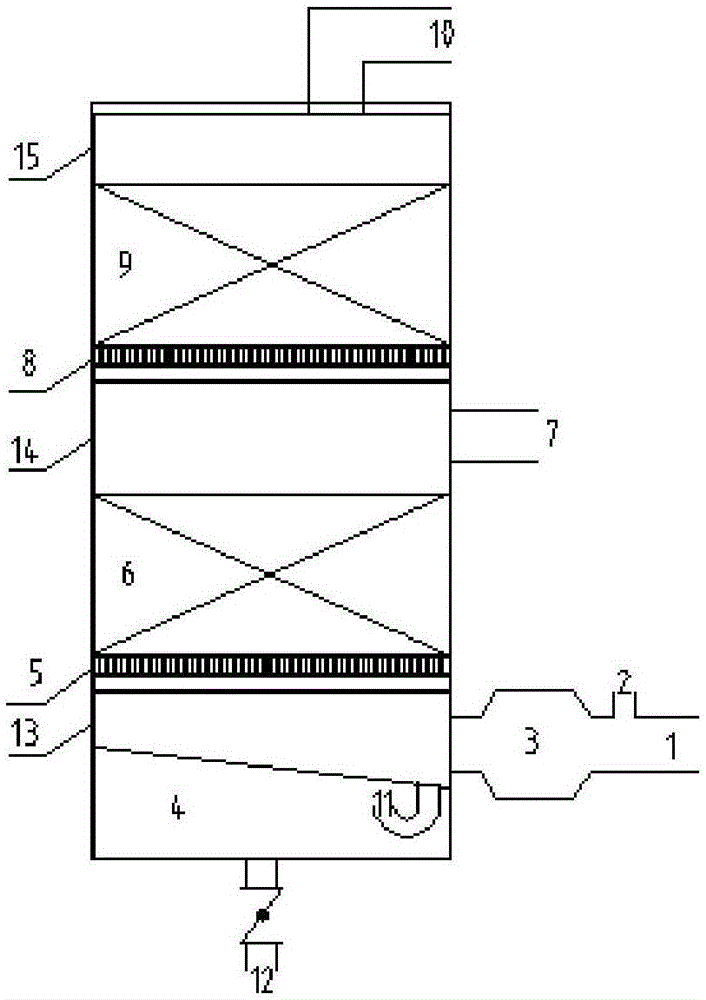

[0038] In this embodiment, the treated exhaust gas: the concentration of sulfur dioxide is 400mg / Nm 3 , the concentration of nitrogen oxides is 800mg / Nm 3 The coking tail gas, the gas volume is about 1000Nm 3 / h, the temperature is about 150°C.

[0039] S1. Desulfurization stage: the industrial flue gas is introduced from the intake pipe 1, and is initially mixed with the saturated water vapor from the steam inlet 2, then enters the pipeline buffer tank 3 for further mixing, and then enters the intake area 13, and runs upward. Enter the activated carbon fiber desulfurization catalyst reaction bed in the desulfurization zone 6 through the grid one 5, and the superficial gas velocity in the desulfurization zone 6 is controlled at 800h -1 , the sulfur dioxide, oxygen, and water vapor in the industrial flue gas are catalyzed and oxidized by the activated carbon fiber desulfurization catalyst to generate sulfuric acid, and the sulfuric acid gradually accumulates under the action ...

Embodiment 2

[0043] In this embodiment, the treated exhaust gas: the concentration of sulfur dioxide is 2000mg / Nm 3 , the concentration of nitrogen oxides is 500mg / Nm 3 industrial boiler exhaust gas, the gas volume is about 20000Nm 3 / h, the temperature is about 160°C.

[0044] S1. Desulfurization stage: the industrial flue gas is introduced from the intake pipe 1, and is initially mixed with the saturated water vapor from the steam inlet 2, then enters the pipeline buffer tank 3 for further mixing, and then enters the intake area 13, and runs upward. Enter the activated carbon fiber desulfurization catalyst reaction bed in the desulfurization zone 6 through the grid 15, and the superficial gas velocity in the desulfurization zone 6 is controlled at 800h -1 , the sulfur dioxide, oxygen, and water vapor in the industrial flue gas are catalyzed and oxidized by the activated carbon fiber desulfurization catalyst to generate sulfuric acid, and the sulfuric acid gradually accumulates under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com