Welding tool and method for airtight type high silicon aluminum package shell body

A technology for encapsulating shells and welding tooling, applied in welding equipment, laser welding equipment, manufacturing tools, etc., can solve the problem of affecting the quality of packaging, affecting the high air tightness, high strength, and thermal stability of electronic packaging joints. Applicable to welding methods and welding tooling, etc., to achieve the effect of improving welding quality, small thermal deformation, and good welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

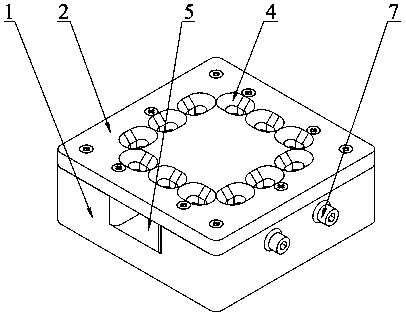

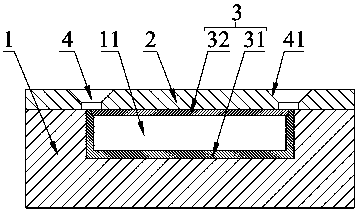

[0036] Such as Figure 1-5 As shown, a welding tool for an airtight high-silicon-aluminum packaging shell includes a base 1 and a pressure plate 2, the base 1 is made of 6-series aluminum alloy, and the pressure plate 2 is made of stainless steel. The base 1 is provided with a limit groove 11 adapted to the shape of the packaging case 3, and the pressure plate 2 is provided with a number of flow guide grooves 4 passing through the pressure plate 2. When the pressure plate 2 and the base 1 are connected, the guide The launder 4 communicates with the area to be welded of the packaging case 3 .

[0037]In this embodiment, a welding tool for hermetically sealing a high-silicon-aluminum packaging case uses a pressure plate 2 made of a specific material to restrict the packaging case 3 in a base 1 made of a specific material, so that the packaging case 3 Effective position restriction is obtained during the welding process to ensure the welding quality and avoid welding deformation...

Embodiment 2

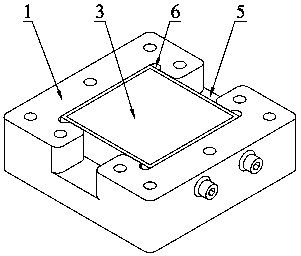

[0043] Such as Figure 1-5 As shown, a welding tool for an airtight high-silicon-aluminum packaging case of this embodiment has the same structure as that of Embodiment 1, the difference is that: the base 1 is provided with at least one communication limiting groove 11 Notch with external space5.

[0044] A welding tool for an airtight high-silicon-aluminum packaging case in this embodiment preferably has two notches 5 arranged on the base 1, and the two notches 5 are respectively located on the two opposite side walls of the base 1, and the notches 5 runs through the top and bottom surfaces of the base 1. On the one hand, it is convenient for the air in the welding tool to be discharged from the gap 5, and it is convenient to embed the package shell 3 into the base 1. On the other hand, the heat generated during welding is dissipated from the gap 5, so as to avoid heat in the Accumulation in the limit groove 11 affects the service life of the electronic devices in the packag...

Embodiment 3

[0046] Such as Figure 1-6 As shown, a welding method for an airtight high-silicon-aluminum packaging casing, the packaging casing 3 includes a casing 31 and a cover plate 32, and the casing 31 and the cover plate 32 are embedded and fitted. The penetration direction of the welding seam 8 of the shell 31 and the cover plate 32 is perpendicular to the front direction of the cover plate 32, including the following steps: Step 1: Assemble the packaging shell 3: Insert the cover plate 32 into the shell 31 to complete the package shell 3 assembly; Step 2: Assembling the welding tool: embed the packaging shell 3 into the base 1 of the welding tool, and fix it by the pressure plate 2 to complete the assembly of the welding tool; Step 3: Laser spot welding: use the laser head in the diversion groove 4 Spot weld the weld 8; step 4: set the positioning piece 7: adjust the positioning piece 7 on the base 1, and limit the packaging shell 3 in the base 1 through the positioning piece 7; st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com