Vibrating solid-liquid separator

A solid-liquid separator and vibratory technology, which is applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems of large project investment costs, achieve low equipment manufacturing costs and use costs, and facilitate recycling. Avoid the effect of screen mesh clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

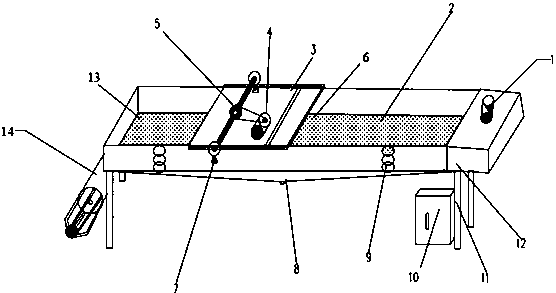

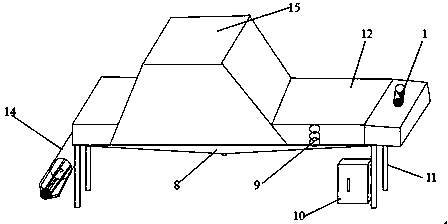

[0022] Such as figure 1 , figure 2 As shown, a vibrating solid-liquid separator includes a water inlet 1 , a screen 2 , a vibrating device 3 , an elastic component 9 , a frame 12 and a discharge port 13 .

[0023] One end of the frame 12 is provided with a water inlet 1, the other end is provided with a discharge port 13, an elastic component 9 is assembled below the frame 12, a screen 2 is housed in the frame 12, and one end near the discharge port 13 is also assembled on the frame 12. There is a vibrating device 3 driven by a motor 4, and a pendulum 7 is installed on both sides of the vibrating device 3.

[0024] The screen 2 is assembled in the frame with an inclination angle of 0°~10°, the screen 2 is covered with a partition, and the vibrating device 3 is assembled ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com