Leaching treatment method and system for heavy metal pollution bottom sediment in ephemeral stream

A technology of contaminated bottom sludge and treatment methods, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., and can solve the problem of unclear design, specific structure and application description, leaching Issues such as strength limitation, leaching ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

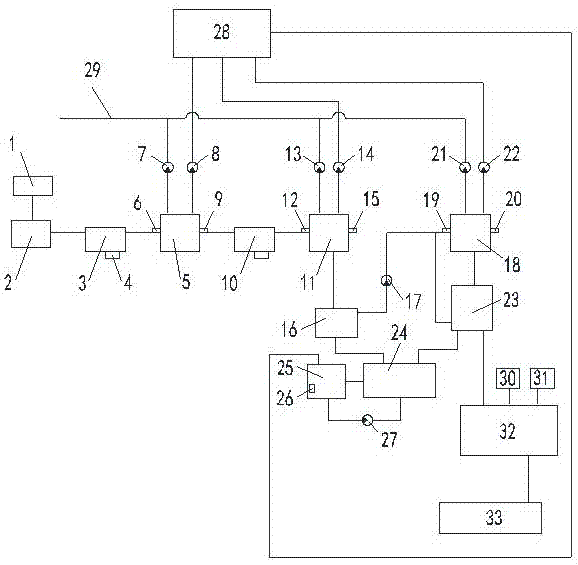

[0092] like figure 1 As shown, the seasonal river heavy metal polluted sediment leaching system of the present invention includes a rock washing system, a sand washing system, a vibrating screen 18 , a water supply pipeline 27 and a drug dissolving device 26 . The stone washing system, the sand washing system and the vibrating screen 18 are all connected with the water supply pipeline 29 and the dissolving device 28 . The water supply pipeline 29 is used for providing rinsing water, and the medicine dissolving device 28 is used for preparing the rinsing liquid.

[0093] The stone washing system includes a dispersing feeder 2, a stone washing conveyor 3 and a roller stone washing machine 5. The dispersing feeder 2, the stone washing conveyor 3 and the roller stone washing machine 5 are arranged in sequence, the outlet of the dispersing feeder 2 is connected with the input end of the stone washing conveyor 3, and the output end of the stone washing conveyor 3 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com