Supercritical hydrothermal combustion reactor for recovering salt from organic wastewater and application thereof

A technology of supercritical water and hydrothermal combustion, which is applied in water/sewage treatment, heating water/sewage treatment, oxidized water/sewage treatment, etc. It can solve problems such as difficult large-scale application, and save equipment cost and operating cost, Energy saving and energy saving effect

Pending Publication Date: 2020-07-31

成都九翼环保科技有限公司

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In practical engineering applications, SCWO technology is difficult to achieve large-scale applicat

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

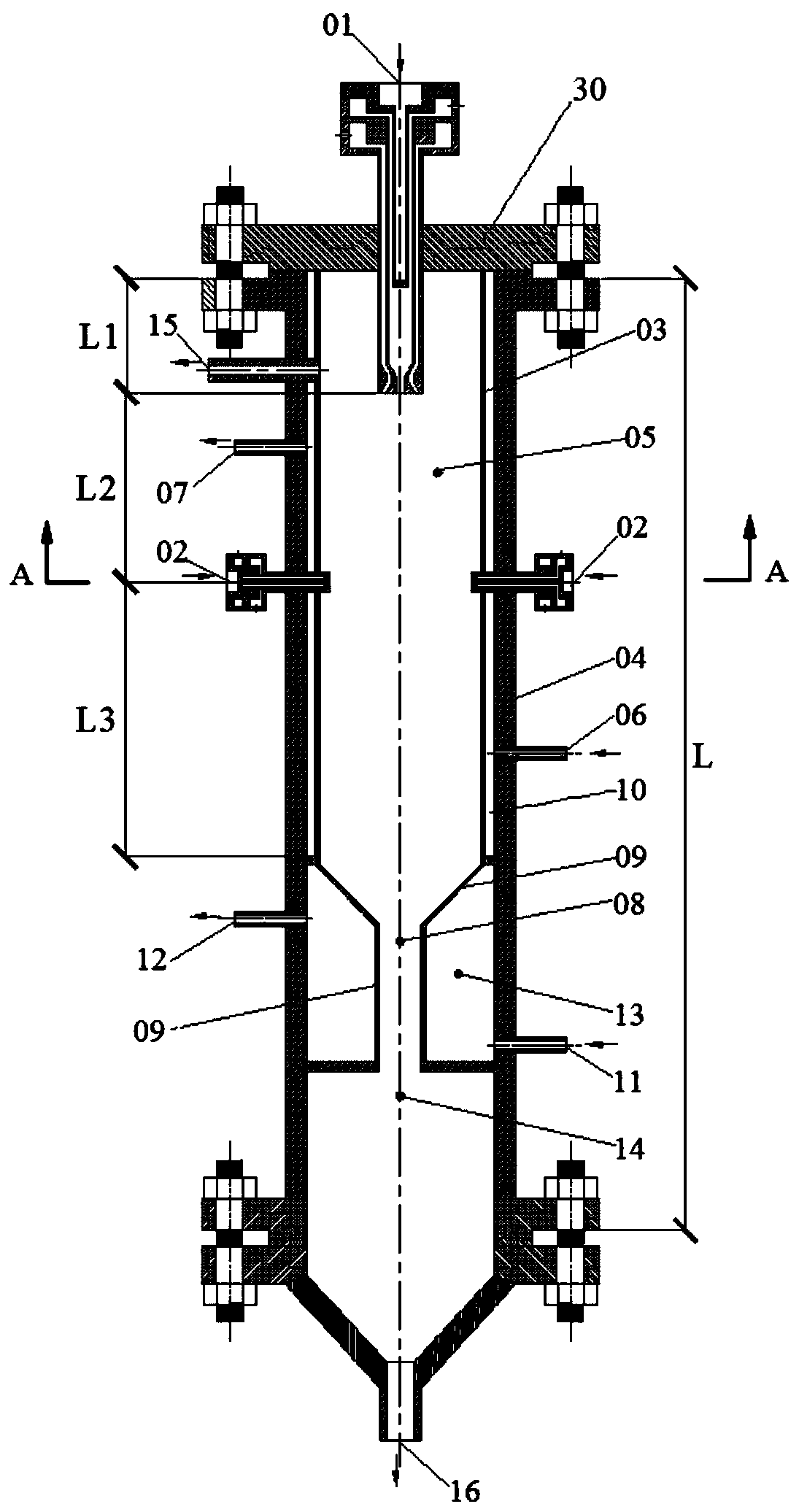

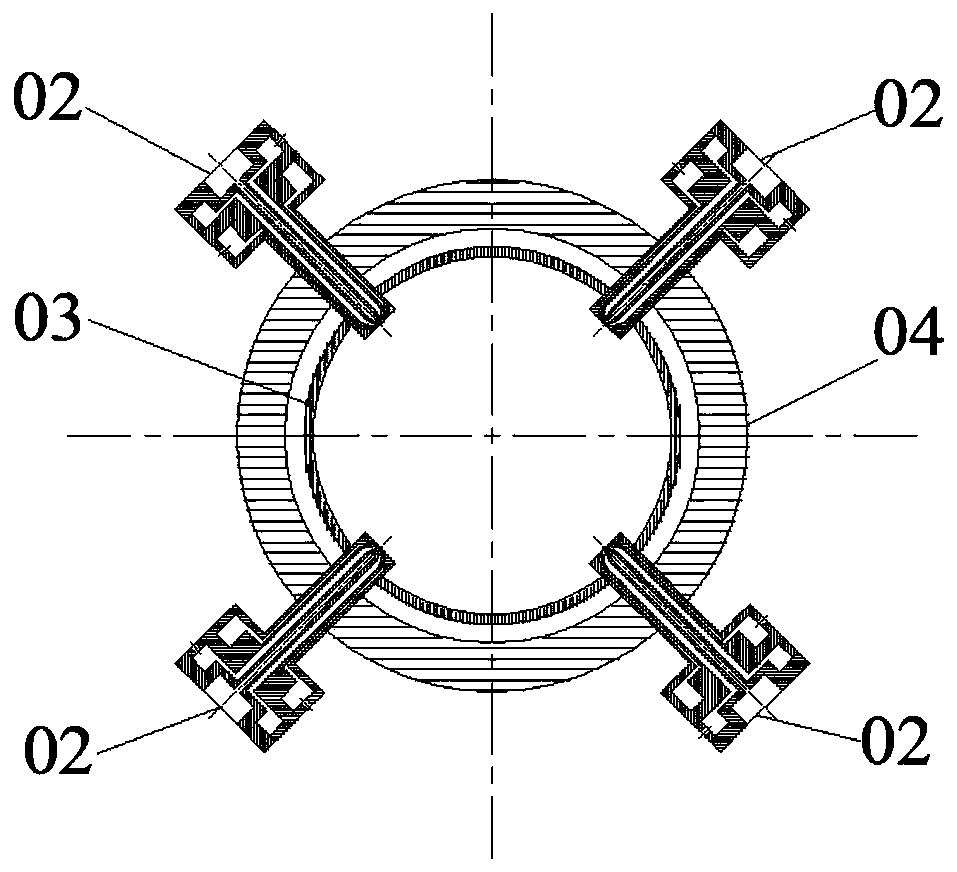

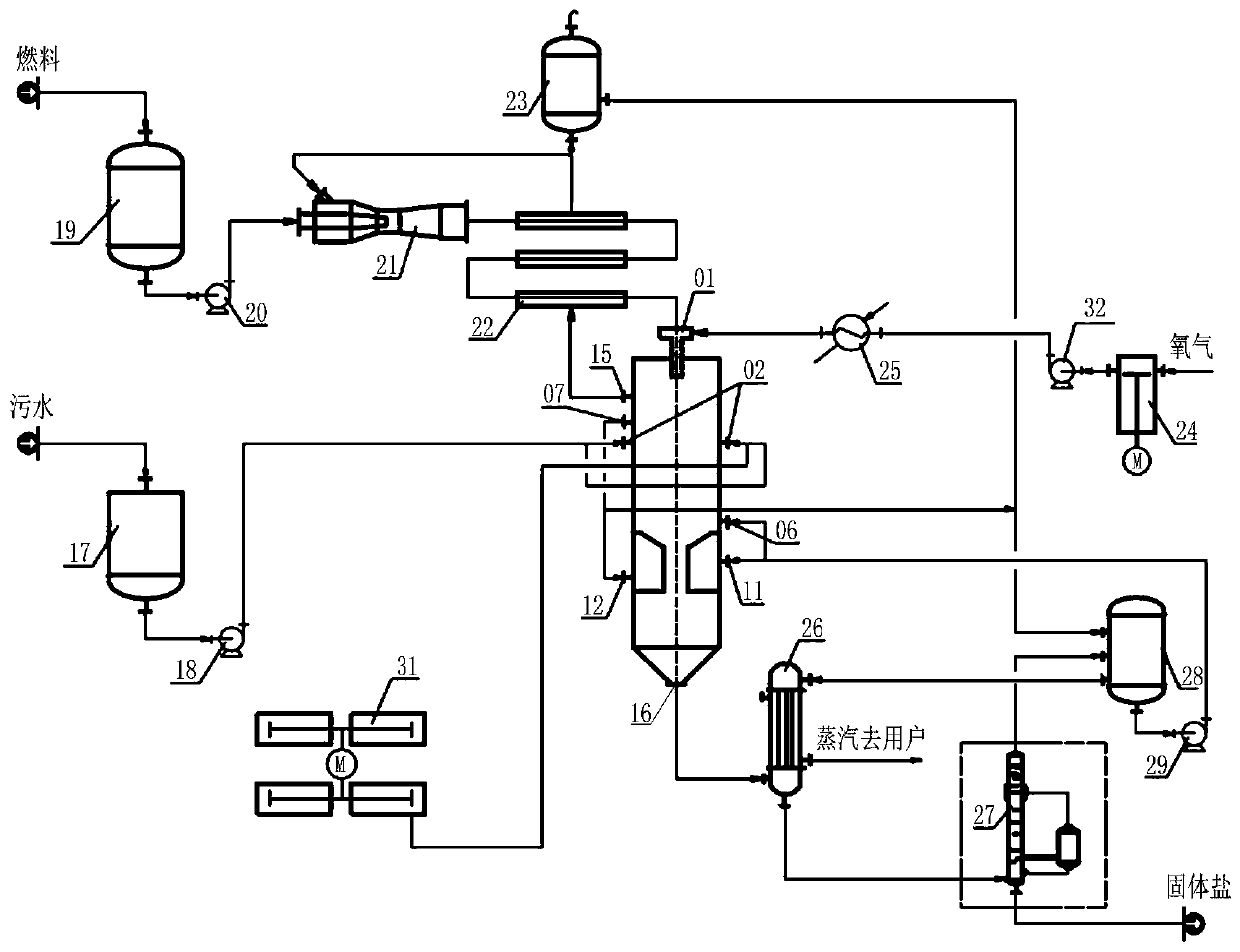

The invention relates to the field of high-salt-content organic wastewater treatment and resource utilization, in particular to a supercritical hydrothermal combustion reactor for recovering salt fromorganic wastewater and application thereof. The reactor comprises a top cover and a cylindrical cavity defined by a pressure bearing wall; wherein the cylindrical cavity comprises a hydrothermal combustion reaction chamber, a chilling chamber and a subcritical water chamber which are in fluid communication from top to bottom; an annular gap between an evaporation wall of the hydrothermal combustion reaction chamber and the pressure bearing wall is an evaporation wall area; a first gas-liquid mixed spraying device is mounted on the top cover; a purified water outlet is formed in the upper partof the side wall of the hydrothermal combustion reaction chamber, and a second gas-liquid mixed spraying device is mounted in the middle of the side wall; an annular space between the permeation wallof the chilling chamber and the pressure bearing wall is a cooling water chamber; and a high-salt water outlet is formed in the bottom of the subcritical water chamber. The reactor can effectively degrade organic matters in wastewater, and salt meeting industrial standards can be obtained after the obtained high-salinity water is subjected to evaporative crystallization.

Description

technical field [0001] The invention relates to the field of high-salt organic wastewater treatment and resource utilization, in particular to a supercritical hydrothermal combustion reactor, system and process for recovering salt from organic wastewater. Background technique [0002] Industrial wastewater is an important part of the field of water pollution control. The discharge of high-salt sewage in industrial sewage is increasing year by year. This type of wastewater has high salt content, complex components, and high toxicity, which brings great challenges to the current wastewater treatment and recycling. This type of wastewater mainly comes from the production process of pesticide, chemical, pharmaceutical, printing and dyeing, coal chemical and other chemical industries, as well as oil and gas mining industries. In addition, it also includes concentrated brine produced in other wastewater treatment processes such as reverse osmosis, electrodialysis, and evaporatio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F1/02C02F1/72C02F9/10C02F101/10C02F101/30

CPCC02F1/02C02F1/04C02F1/727C02F2101/10C02F2101/30C02F2301/08

Inventor 张克江

Owner 成都九翼环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com