Auxiliary airflow type pneumatic on-demand sprayer for reducing diameter of metal droplet

A spray device and air flow technology, applied in the field of additive manufacturing, can solve the problems of restricting the development of metal droplet spraying additive manufacturing technology and affecting the quality of formed parts, achieving a simple structure, ensuring original performance, and improving molding accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

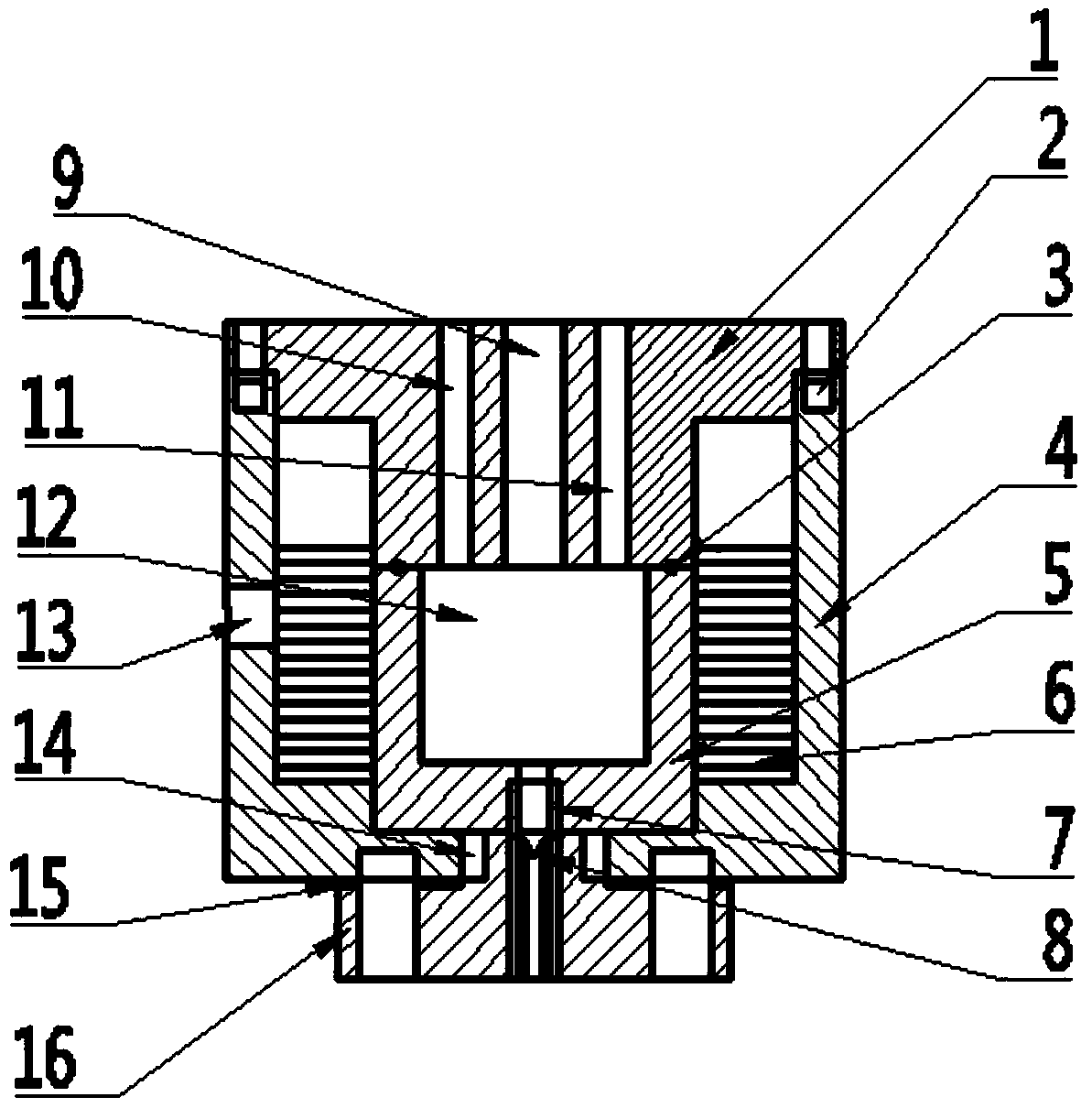

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] a) Since the invention needs to ensure the size of the droplet generation, it has higher requirements on the diameter of the nozzle hole (8), and the diameter of the nozzle hole (8) is between 50 μm and 200 μm. The setting of the nozzle (7) can facilitate the replacement of nozzles (7) of different sizes. Simultaneously, problems such as difficulty in handling when the nozzle (7) is blocked can also be avoided.

[0023] b) In order to reduce the energy dissipation in the working process of the pneumatic nozzle, the cone angle of the processed nozzle (7) should be less than 90°.

[0024] c) In order to ensure the service life of the pneumatic nozzle (5) and the nozzle (7), the materials are all processed from high temperature resistant ceramics and nickel-chromium alloy.

[0025] d) In order to improve the spraying effect of the pneumatic nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com