Preparation method and application of integrated three-layer structural inorganic oxygen permeating membrane

A three-layer structure and oxygen-permeable membrane technology, applied in chemical instruments and methods, separation methods, semi-permeable membrane separation, etc., can solve the problems of low purity of oxygen production and high cost of air separation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

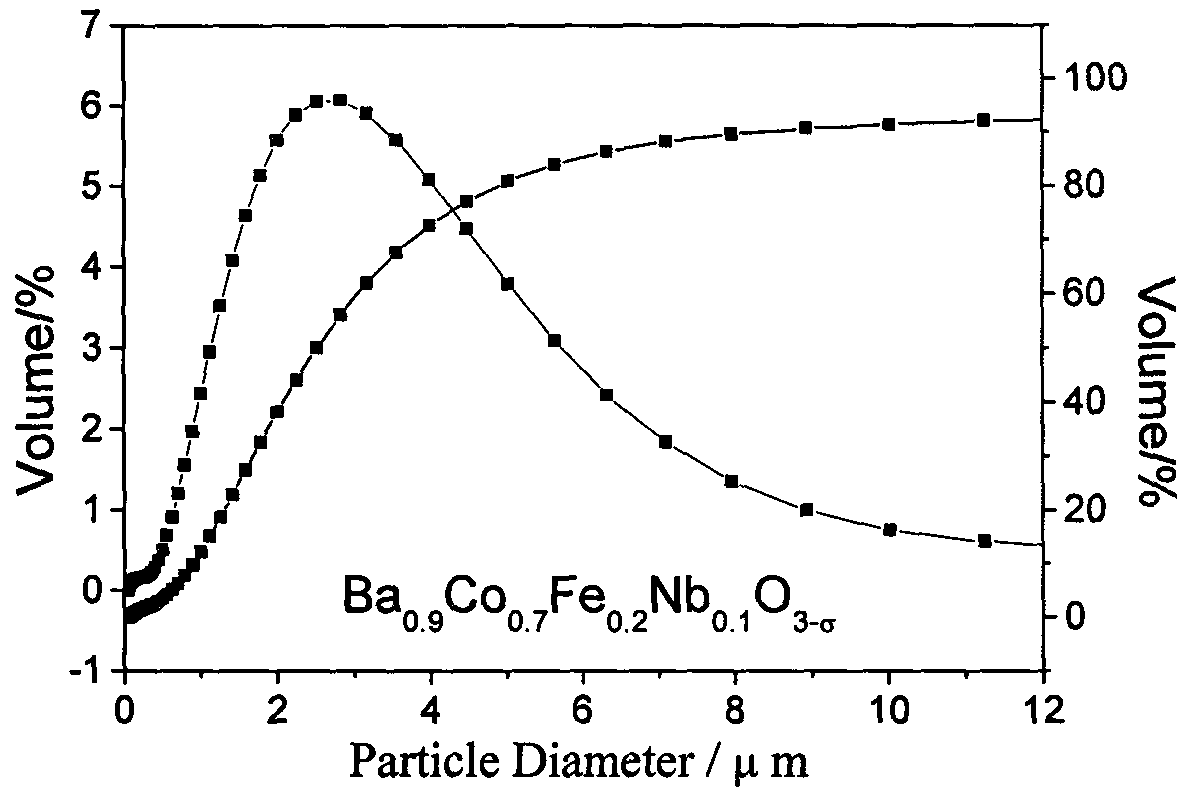

[0019] Weigh BaCO according to the stoichiometric ratio of each content in BCFN 3 、Co 3 o 4 , Fe 2 o 3 and Nb 2 o 5 The analytically pure reagent is placed in a polyurethane ball mill tank equipped with zirconia balls, and absolute ethanol is used as a solvent, and the weight ratio of "material: ball: absolute ethanol" is 1:2:0.8. Put it on a roller ball mill for 48 hours, then dry it in an oven at 78°C and place it in a muffle furnace for calcination at 1000°C for 24 hours, then add zirconia balls and absolute ethanol ball mill for 24 hours according to the above method, and then Dry in an oven at 78°C, and pass through a 200-mesh sieve to obtain BCFN oxide powder. The particle size distribution of the obtained powder is shown in figure 1 .

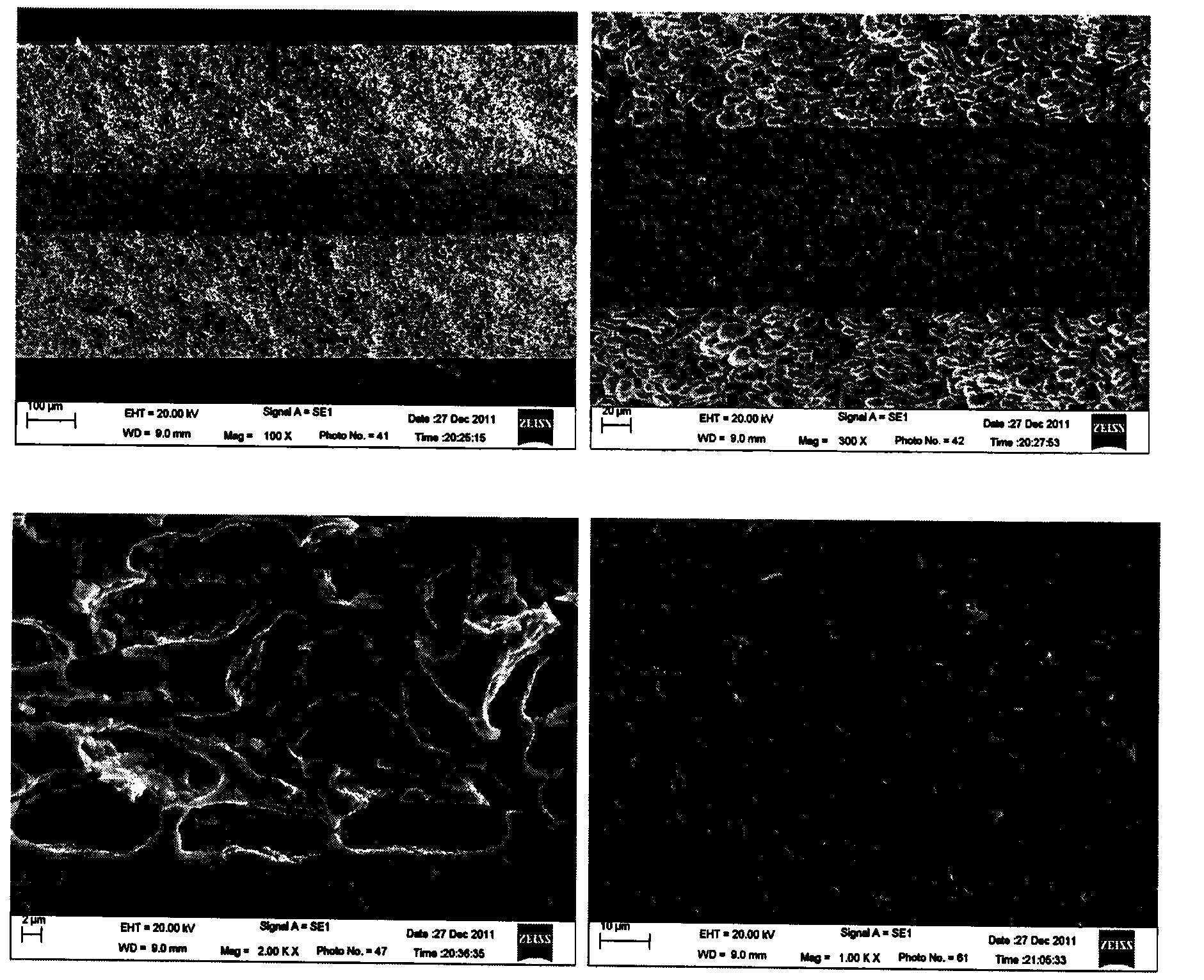

[0020] The dense layer and the porous layer oxygen-permeable membrane were prepared respectively by casting method, and the preparation process of the casting slurry was as follows: add ethanol, butanone and castor oil to the BCFN...

Embodiment 2

[0023] The experiment was carried out at 800-900°C, one point was taken every 25°C, and the heating rate was 2°C / min. Place the oxygen-permeable membrane at one end of the alumina tube with polished smooth ports, and seal it with glass sealant. Synthetic air (21% O 2 +79%N 2 ), the low oxygen partial pressure end was fed with He gas, each flow rate was controlled by a mass flow controller, and the actual flow rate was measured by a soap film flowmeter. The synthetic air and He gas flow rates were controlled to be 135ml min -1 , 90ml·min -1 . After the outlet gas passes through the gas drying pipe, measure its total flow with a soap film flowmeter, and pass it into a gas chromatograph (SP3420A) for composition and content analysis. The results are as follows: Figure 4 shown. It can be seen from the figure that the oxygen permeability of the membrane increases with the increase of temperature. When the temperature rises from 800°C to 900°C, the oxygen permeability of the t...

Embodiment 3

[0025] In the experiment, the oxygen-permeable membrane was placed at one end of an alumina tube with a polished port, and sealed with a glass sealant. Synthetic air (21% O 2 +79%N 2), the low oxygen partial pressure end is fed with He gas, each flow rate is controlled by a mass flow controller, and the actual flow rate is measured by a soap film flowmeter. After the outlet gas passes through the gas drying tube, the total flow rate is measured with a soap film flowmeter, and then passed into a gas chromatograph (SP3420A) for composition and content analysis. In this experiment, at 900°C, by changing the He gas purge flow rate on the low oxygen partial pressure side (He gas flow rate from 60-210ml·min -1 ), tested the variation of the oxygen permeability of the three-layer structure oxygen-permeable membrane reactor, the results are as follows Figure 5 shown. It can be seen from the figure that as the flow rate of He gas increases from 60ml·min -1 Increase to 210ml·min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com