Patents

Literature

31 results about "Soap film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soap films are thin layers of liquid (usually water-based) surrounded by air. For example, if two soap bubbles come into contact, they merge and a thin film is created in between. Thus, foams are composed of a network of films connected by Plateau borders. Films are used as model systems for minimal surfaces, which are widely used in mathematics.

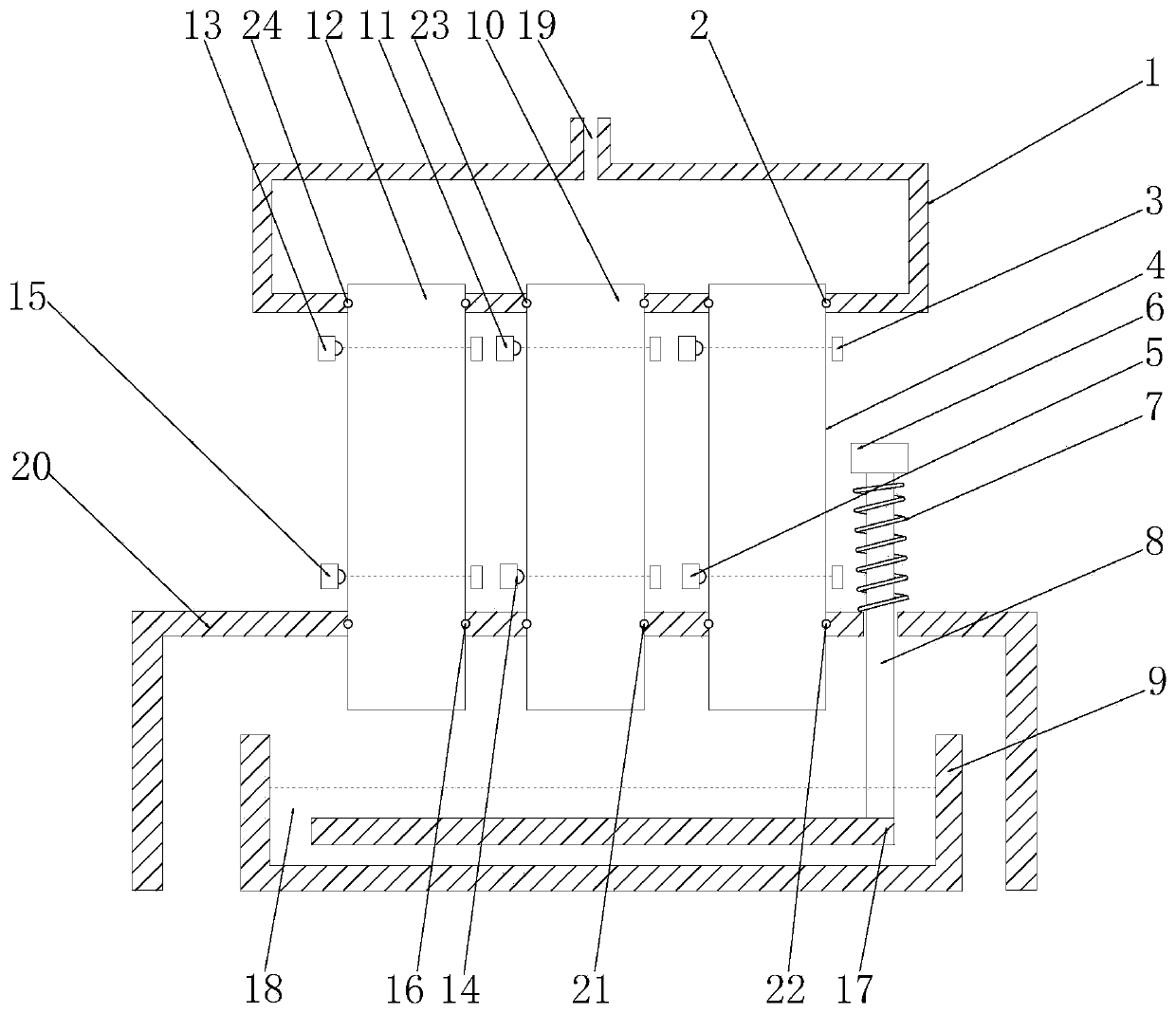

Soap film flowmeter

InactiveCN101464169AAvoiding Difficulties That Affect MeasurementsThe overall structure is simple and reliableVolume meteringVolume/mass flow by differential pressureEngineeringSoap film

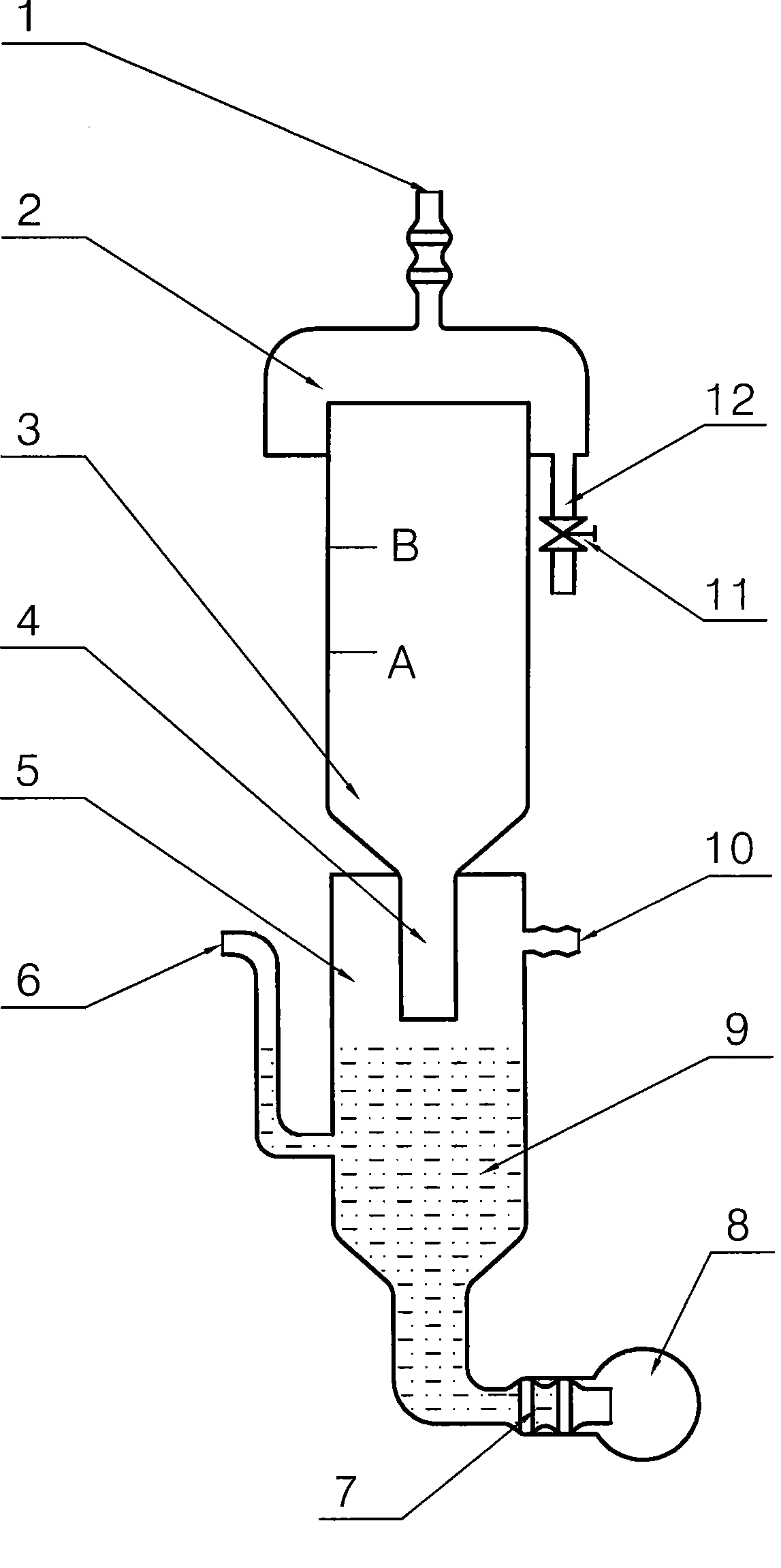

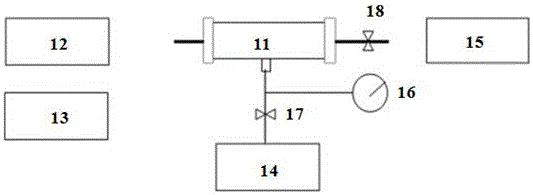

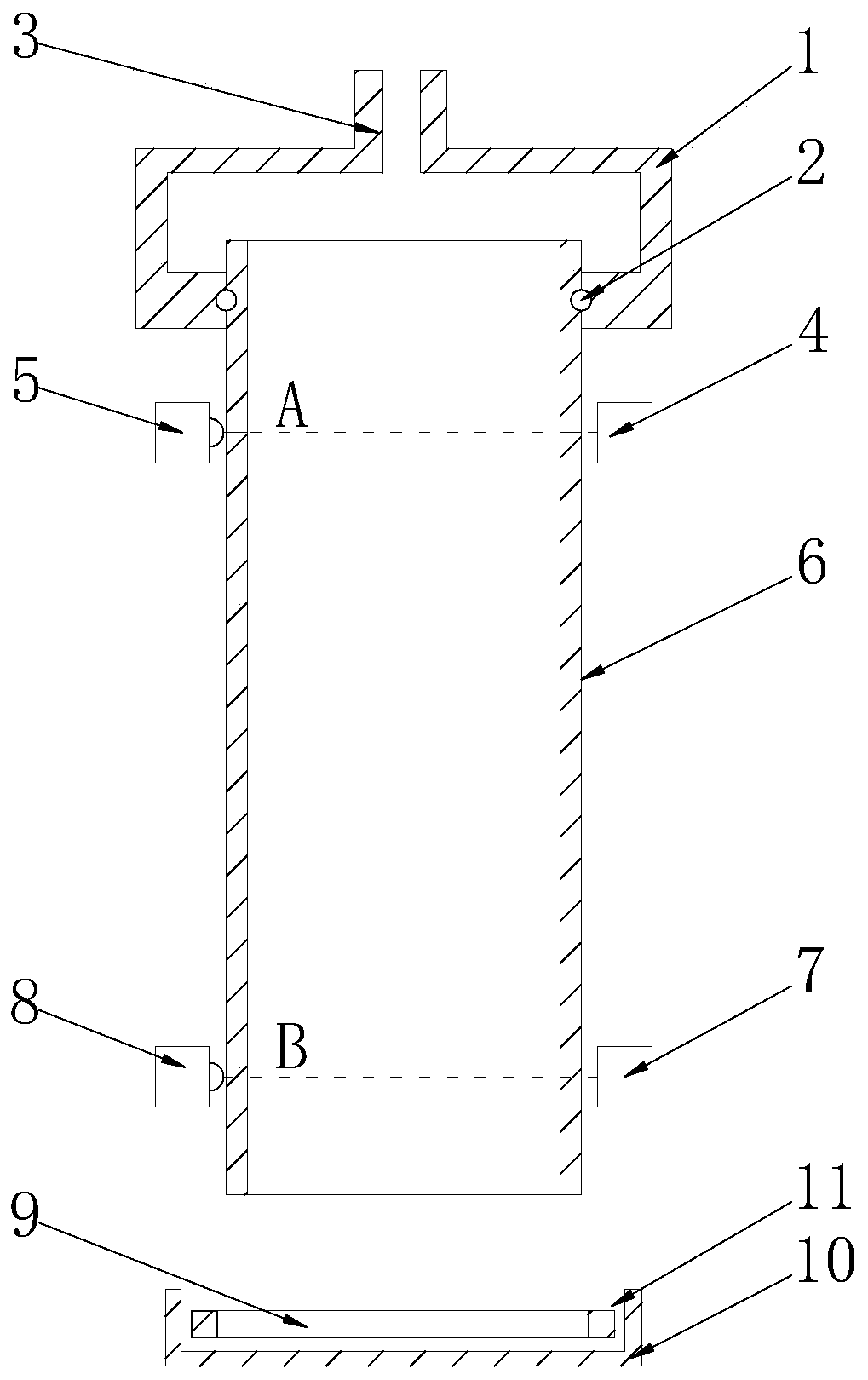

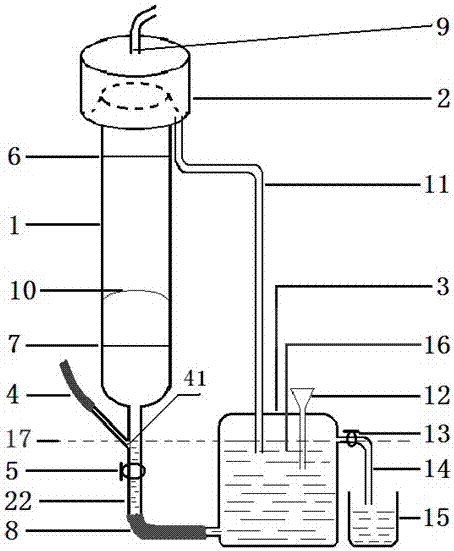

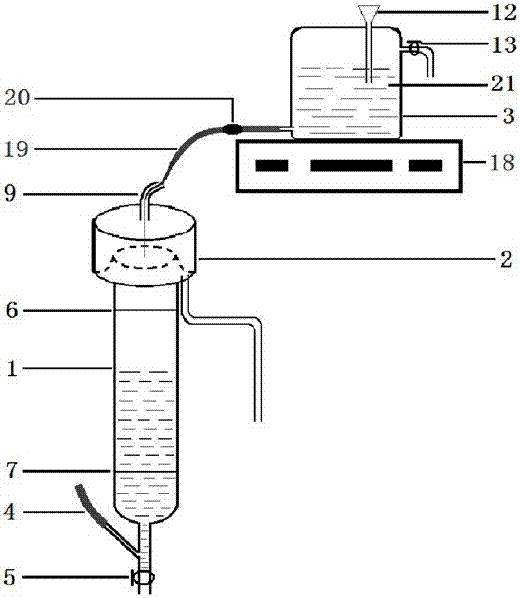

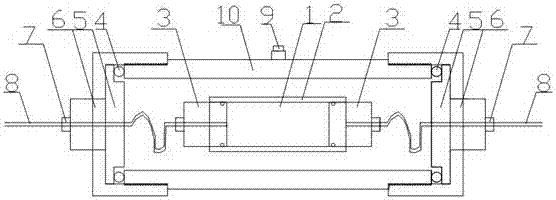

The invention relates to a soap film flowmeter used for measuring gas-flow rate, which comprises a gas outlet, a soap film liquid recycling device, a soap film tube, a soap film production device, a soap film cup, a soap liquid feed inlet, a rubber ball interface, a rubber ball, soap liquid, a gas inlet, a waste soap film liquid outlet and a valve; the soap film liquid recycling device used for collecting waste soap film liquid is positioned above the soap film tube; the soap film production device is positioned under the soap film tube; the gas to be tested flows in through the gas outlet and the soap film cup and flows out through the soap film tube and the gas outlet; the soap film production device produces a soap film through squeezing the rubber ball or by other means; under the action of the pressure of the incoming gas, the soap film is pushed to rise at a uniform speed along the soap film tube; the time for the soap film to pass from one scale position to another on the soap film tube is measured by means of stopwatch measure or photoelectrical detection and the like; the flow rate can be determined through the calculation involving the measure time and the capacity between the two scales on the soap film tube; the soap film comes into the soap film liquid recycling device after rising to the upper end of the soap film tube; and the waste soap film liquid can be removed after the valve is opened.

Owner:王丕征

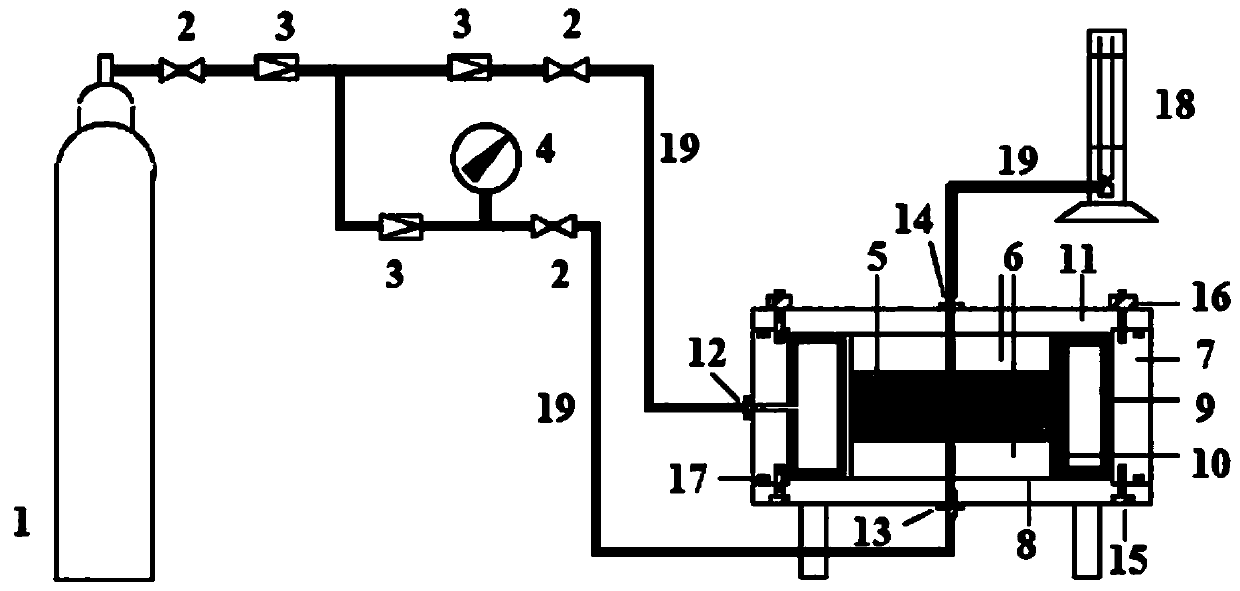

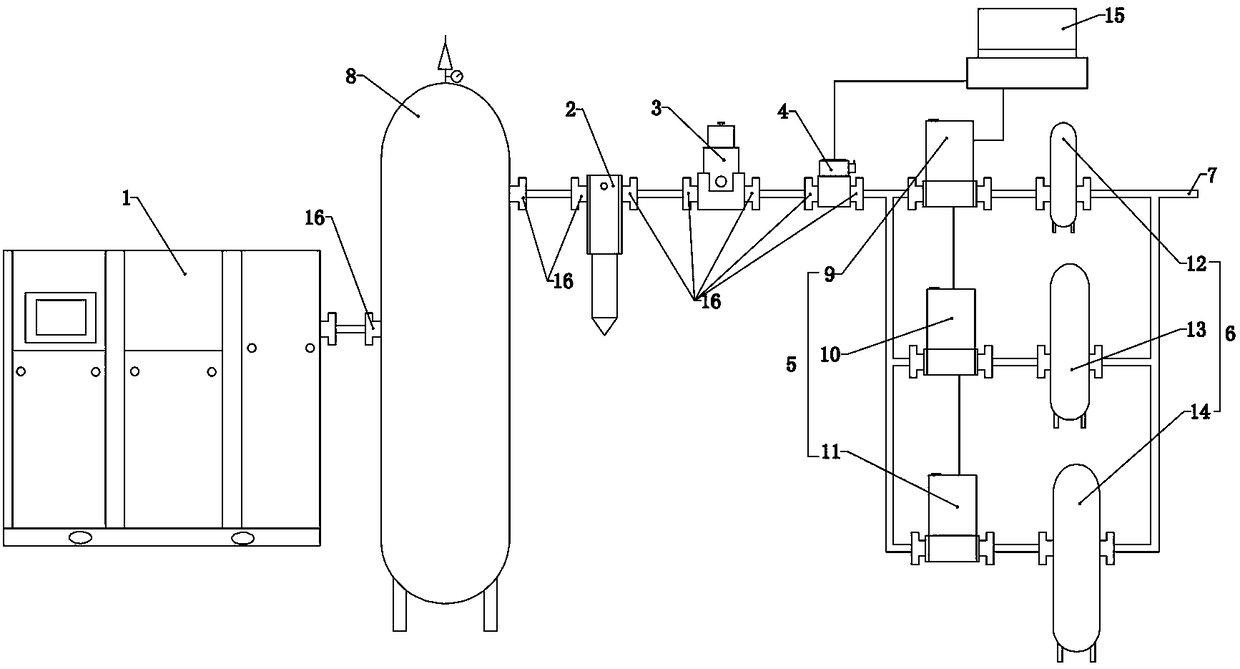

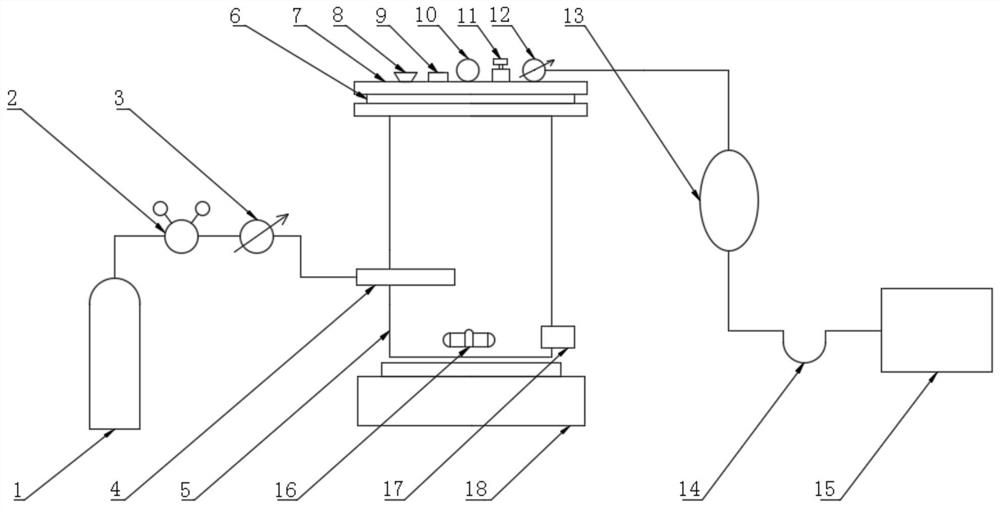

Constant-pressure steady-state gas permeability measuring instrument

InactiveCN103149137AHigh precisionImprove stabilityPermeability/surface area analysisRock coreMeasuring instrument

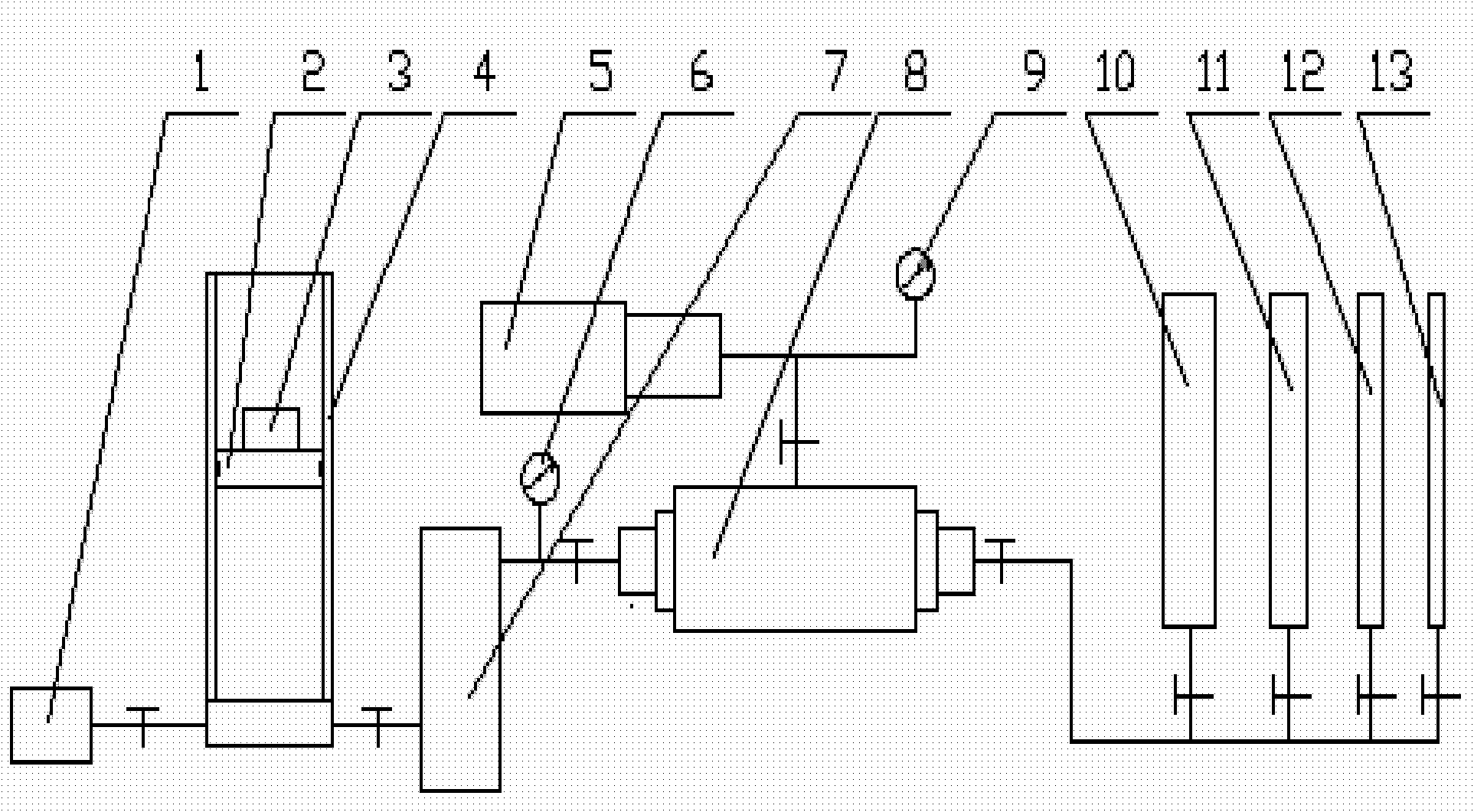

The invention relates to a constant-pressure steady-state gas permeability testing instrument. The constant-pressure steady-state gas permeability testing instrument is characterized in that: a gas storage cylinder (4) is internally provided with a piston (2); the piston (2) is provided with a balancing weight block (3); the left end of a rock core holder (8) is connected with one end of a drier (7) through a pipeline while the other end of the drier (7) is connected with a gas outlet of the gas storage cylinder (8); the gas inlet of the gas storage cylinder (4) is connected with an inflator pump (1) through a pipeline; the right end of the rock core holder (8) is connected with a gas flowmeter and a soap-film gas flowmeter (13) through a pipeline; the outer wall of the rock core holder (8) is provided with a ring press hole; and the ring press hole of the rock core holder (8) is connected with a ring press pump (5) through the pipeline. Based on a steady pressure principle, the constant-pressure steady-state gas permeability testing instrument adopts an internally arranged inflator pump for inflation to stabilize inlet and outlet pressures of the rock core, so that precision and stability of the rock core test are improved, and the testing error of the rock core permeability is controlled within 1%. The constant-pressure steady-state gas permeability testing instrument, disclosed by the invention, has advantages of simple structure, convenient operation, steady performance and good repeatability.

Owner:YANGTZE UNIVERSITY

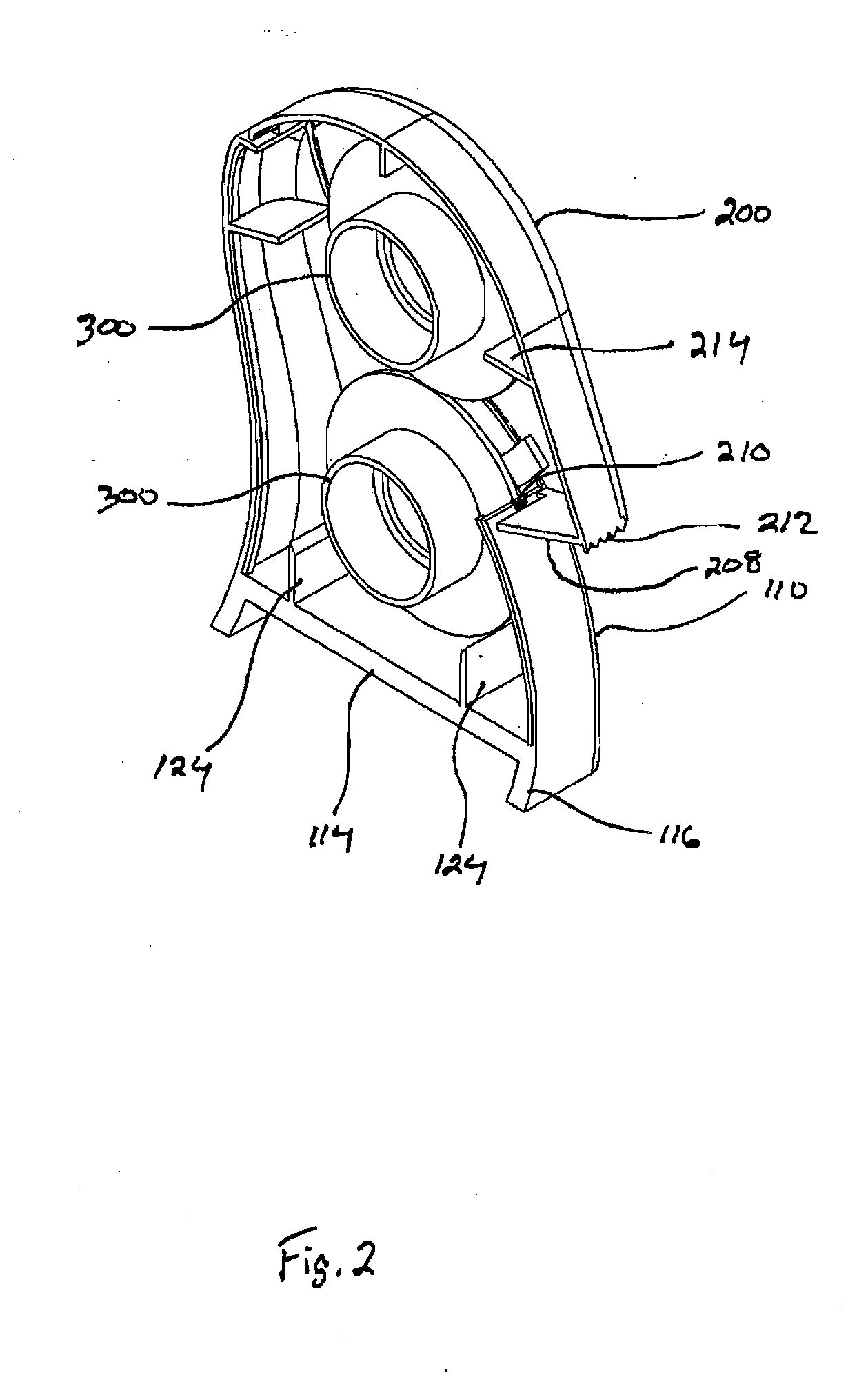

Soap tape dispenser

InactiveUS20100264249A1Minimizes premature activationOptimize allocationContainers for annular articlesFilament handlingWater solubleSoap film

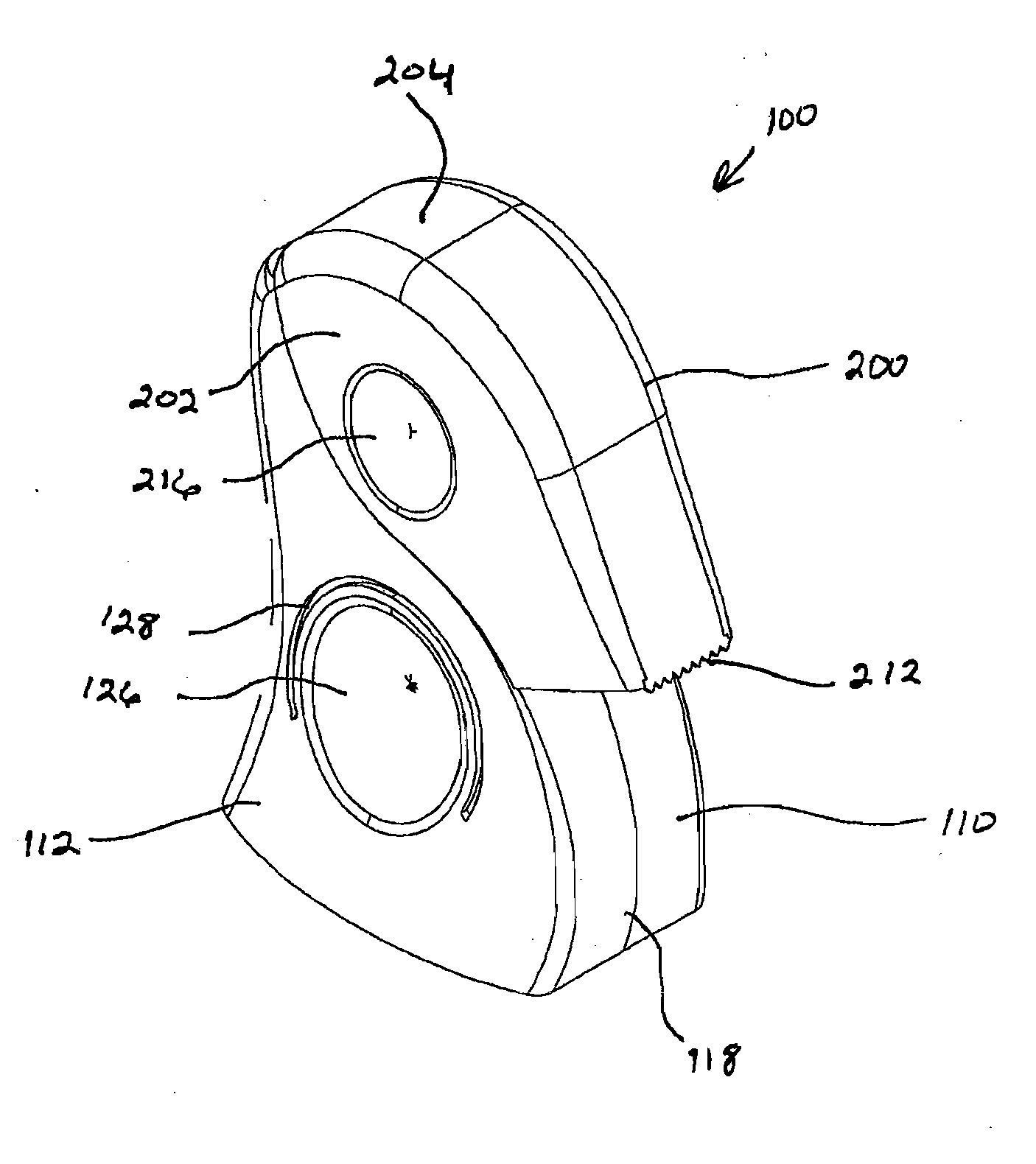

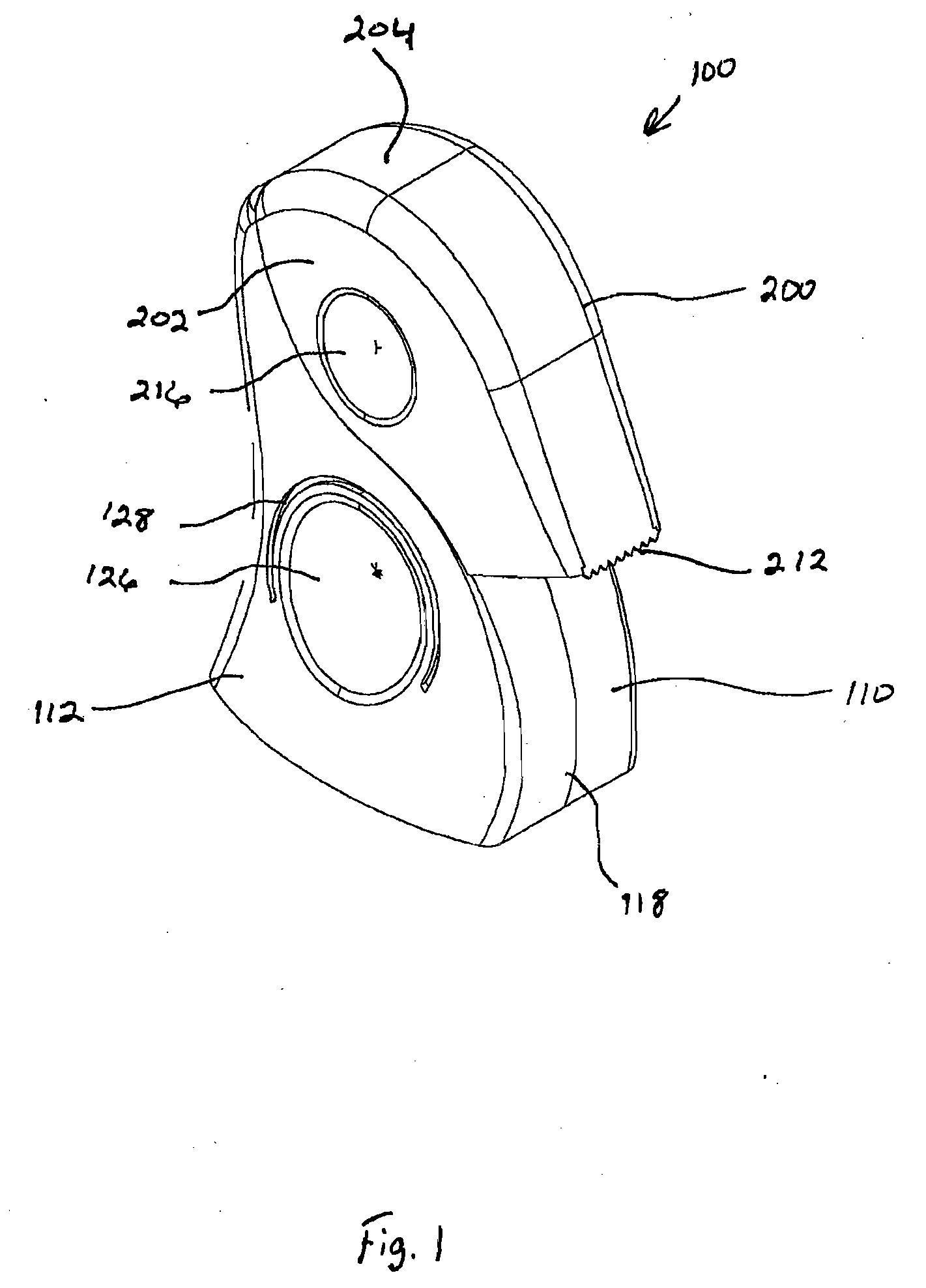

An improved soap film dispensing system includes a dispenser having a dispenser body and a top cover pivotally connected with the dispenser body and at least a first roll suitable for insertion into said dispenser and carrying a length of water soluble soap film having a series of tabbed sections to enhance dispensing of the appropriate amount of soap film to the user.

Owner:KRANSON INDS

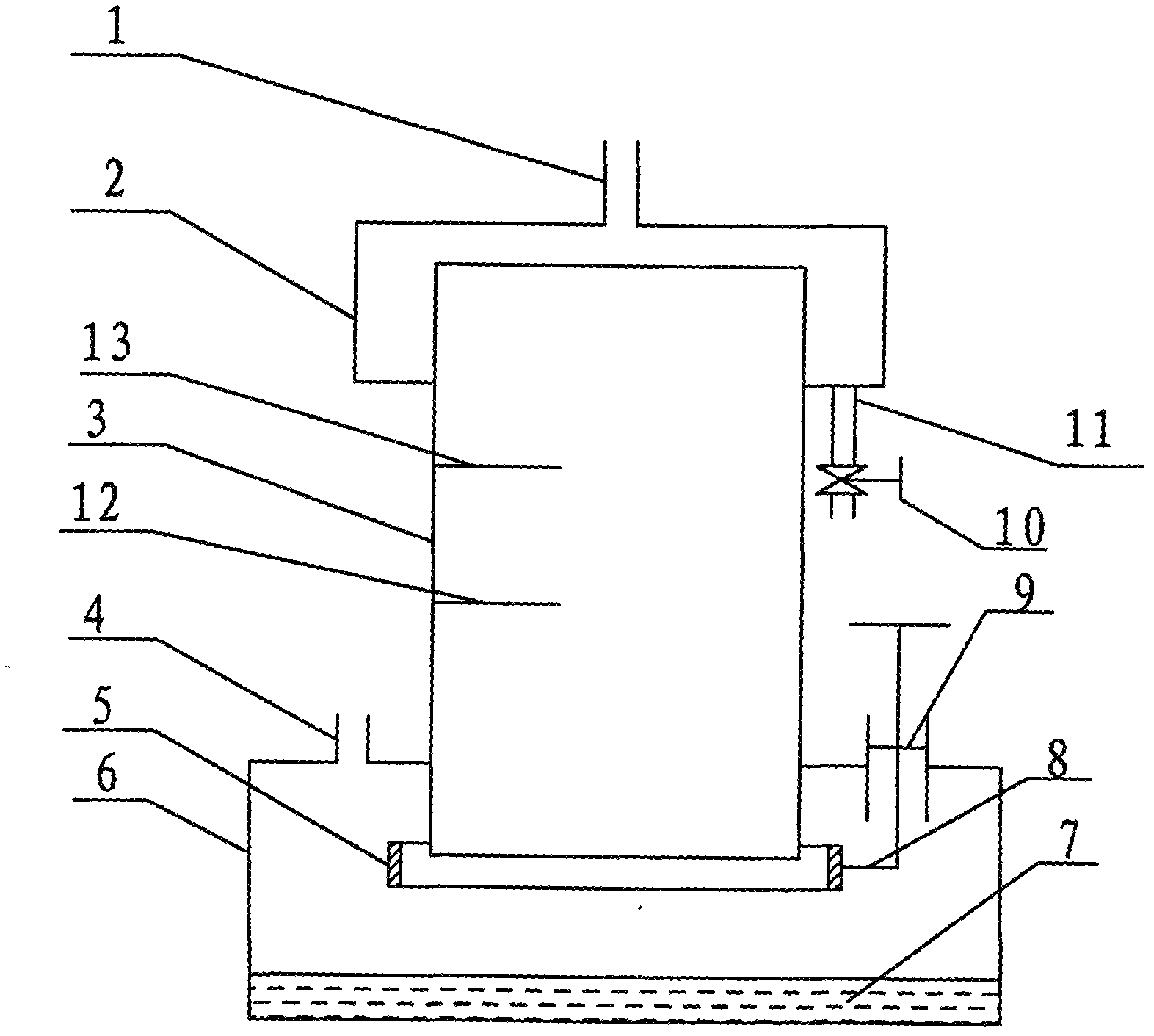

Soap film flowmeter

InactiveCN102147272AExpand the measurement rangeAvoid problems that hinder measurementVolume/mass flow by differential pressureEngineeringSoap film

The invention discloses a soap film flowmeter, which comprises a soap film tube, a gas inlet, a liquid soap cup and liquid soap. The liquid soap is accommodated in the liquid soap cup; the upper part of one side of the liquid soap cup is provided with the gas inlet; the soap film tube is inserted into the liquid soap cup and is in fixed and sealed connection with the liquid soap cup; and the soap film tube is positioned above a liquid level of the liquid soap. The soap film flowmeter is characterized in that: a soap film production device (5) is also arranged between the upper surface of the liquid soap cup (6) and the liquid level of the liquid soap (7); and an internal radial dimension of the soap film production device (5) is not less than a bottom radial dimension of the soap film tube (3). By the soap film flowmeter, the difficulty that the soap film is not easy to produce when a larger flow is measured by the soap film flowmeter is solved, the measurement use range of the soap film flowmeter is broadened, and the waste soap film liquid can be recycled.

Owner:QINGDAO HENGYUAN TECH DEV

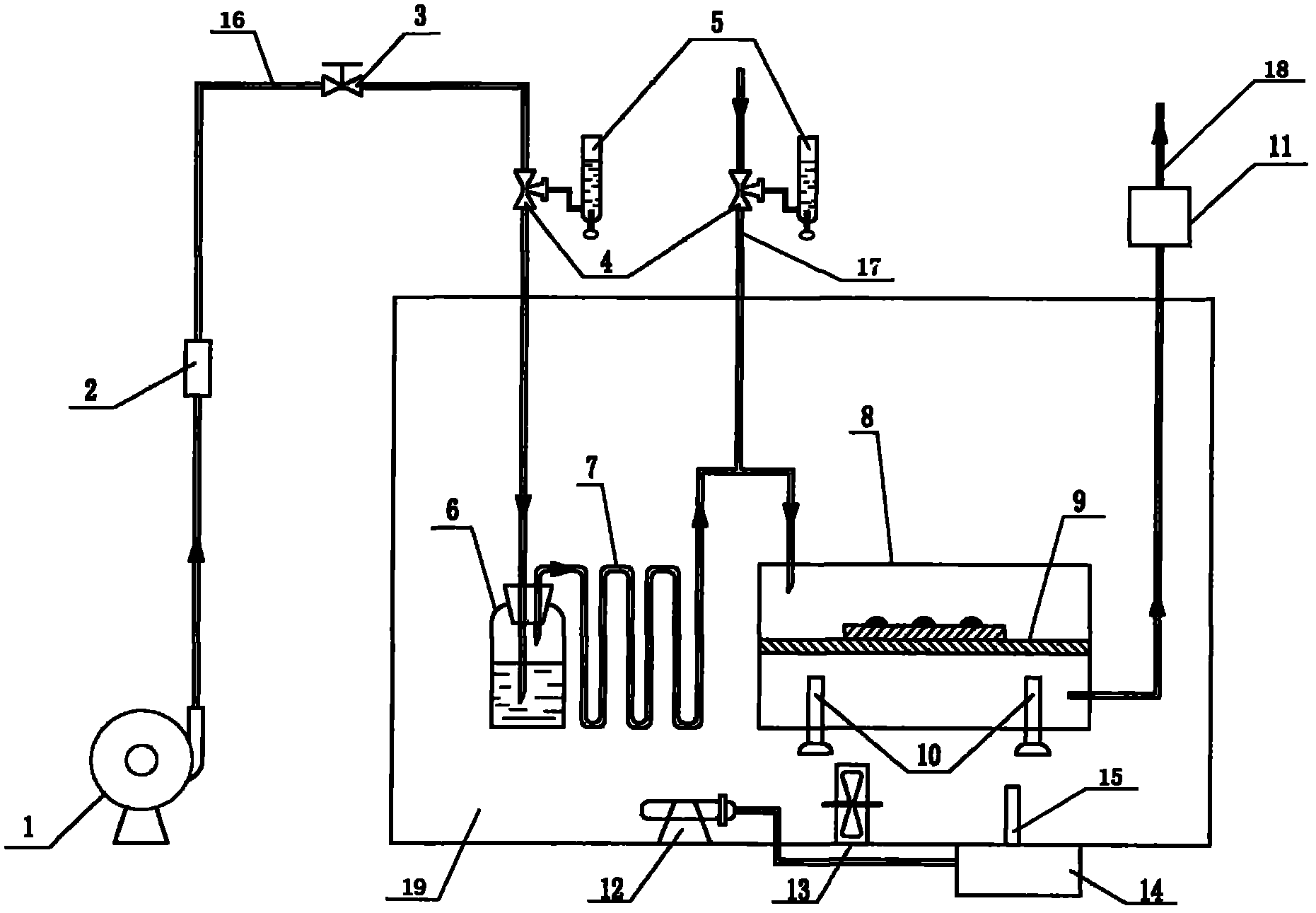

Simulation experimental facility used for determining influence of solid chemicals to metal corrosivity

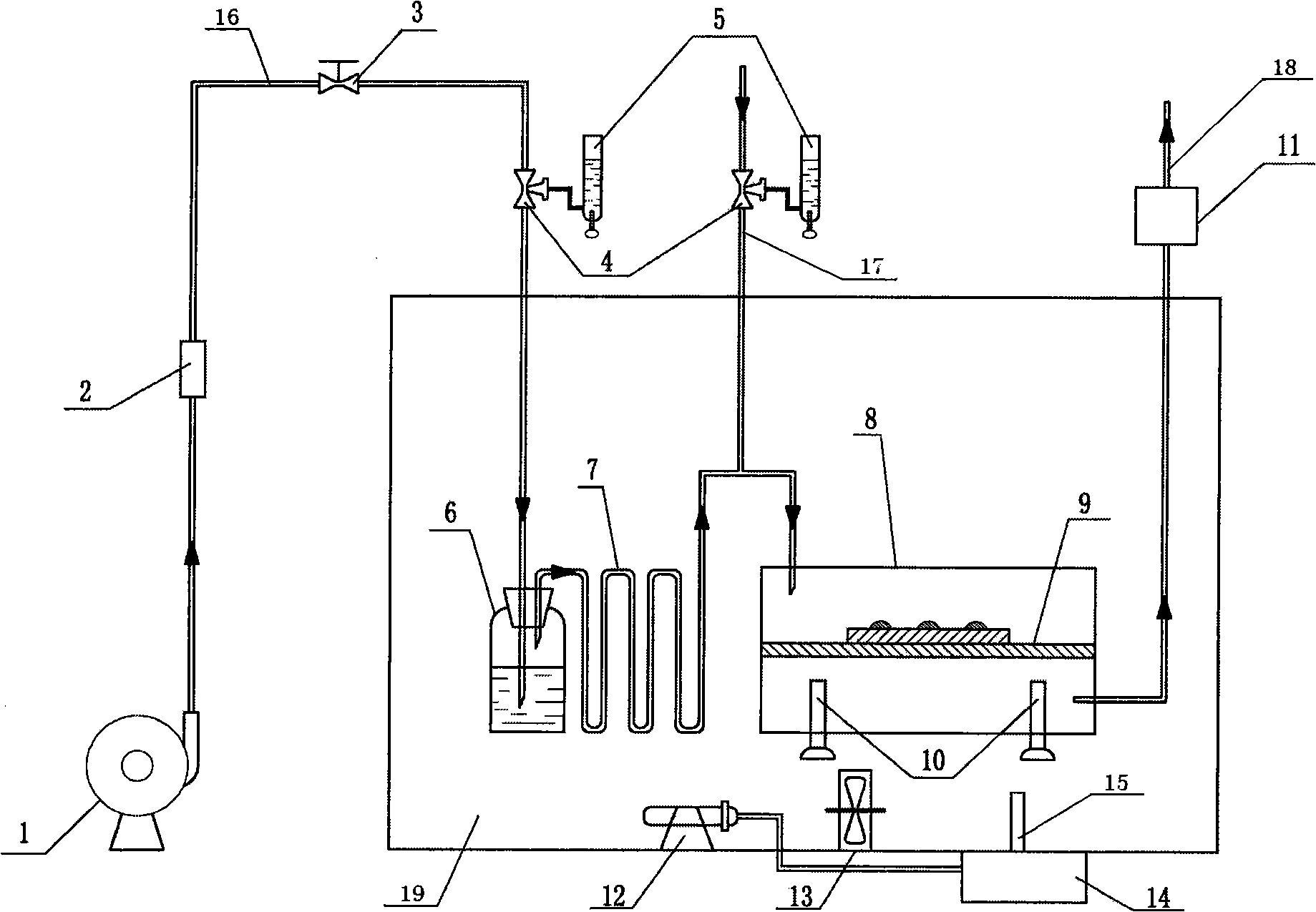

ActiveCN102095829ASimple structureFlexible operationChemical methods analysisChemical industryMeasurement device

The invention relates to a simulation experimental facility used for determining the influence of solid chemicals on the metal corrosivity, comprising an air pump, a filter, a regulating valve, a three-way valve, a soap film flowmeter, a bubbling evaporation bottle, an air preheating coil, an observation room, a shelf, a support, a humidity measurement device, a heating element, a fan, a temperature controller, a probe, an air inlet pipeline, an inlet pipeline for other gases and a box body. Compared with the prior art, the facility in the invention can be widely applied to the fields of environmental protection and chemical industry and even product transportation process, the structure is simple, and the facility is safe and convenient to use.

Owner:SHANGHAI RES INST OF CHEM IND

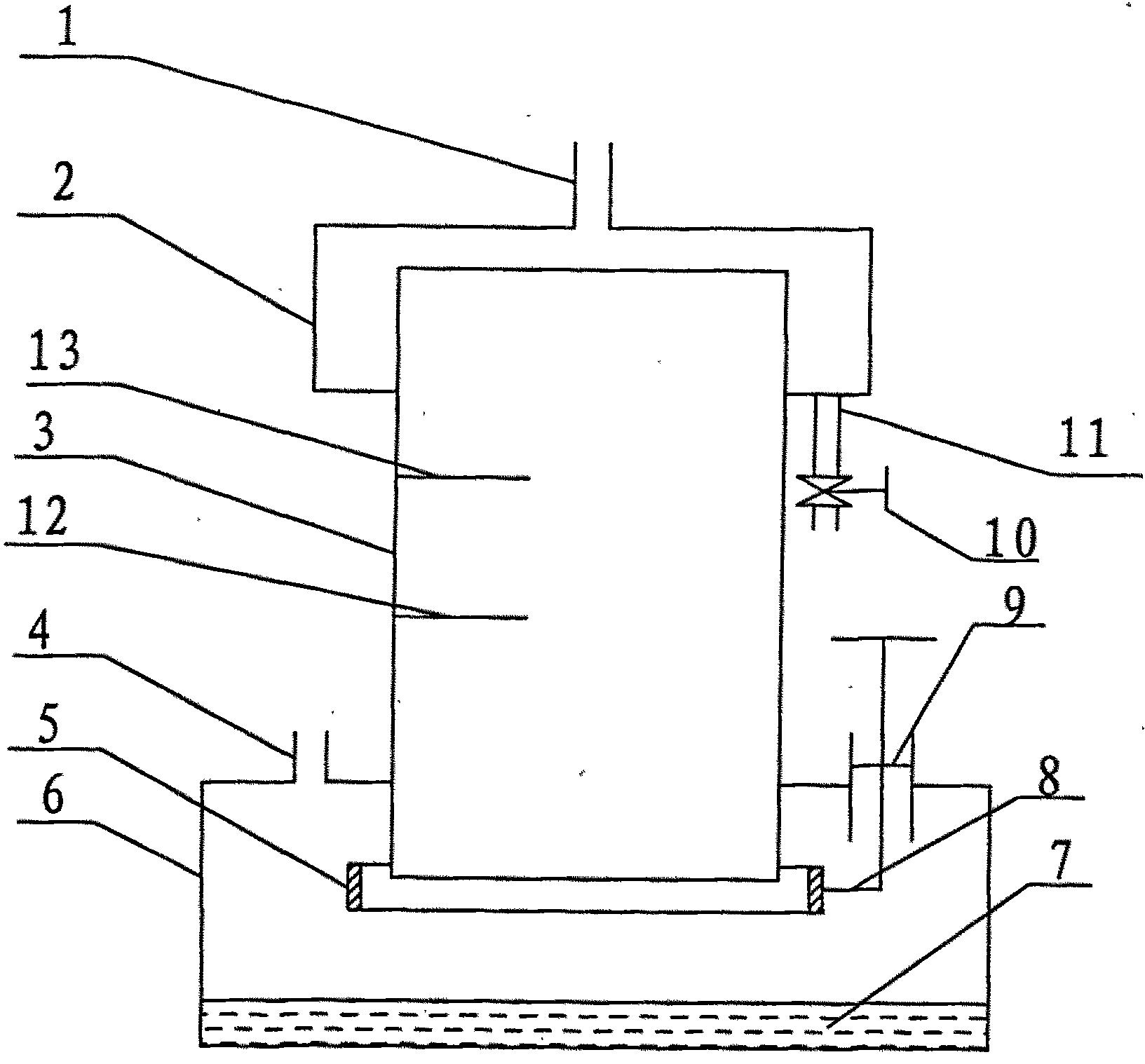

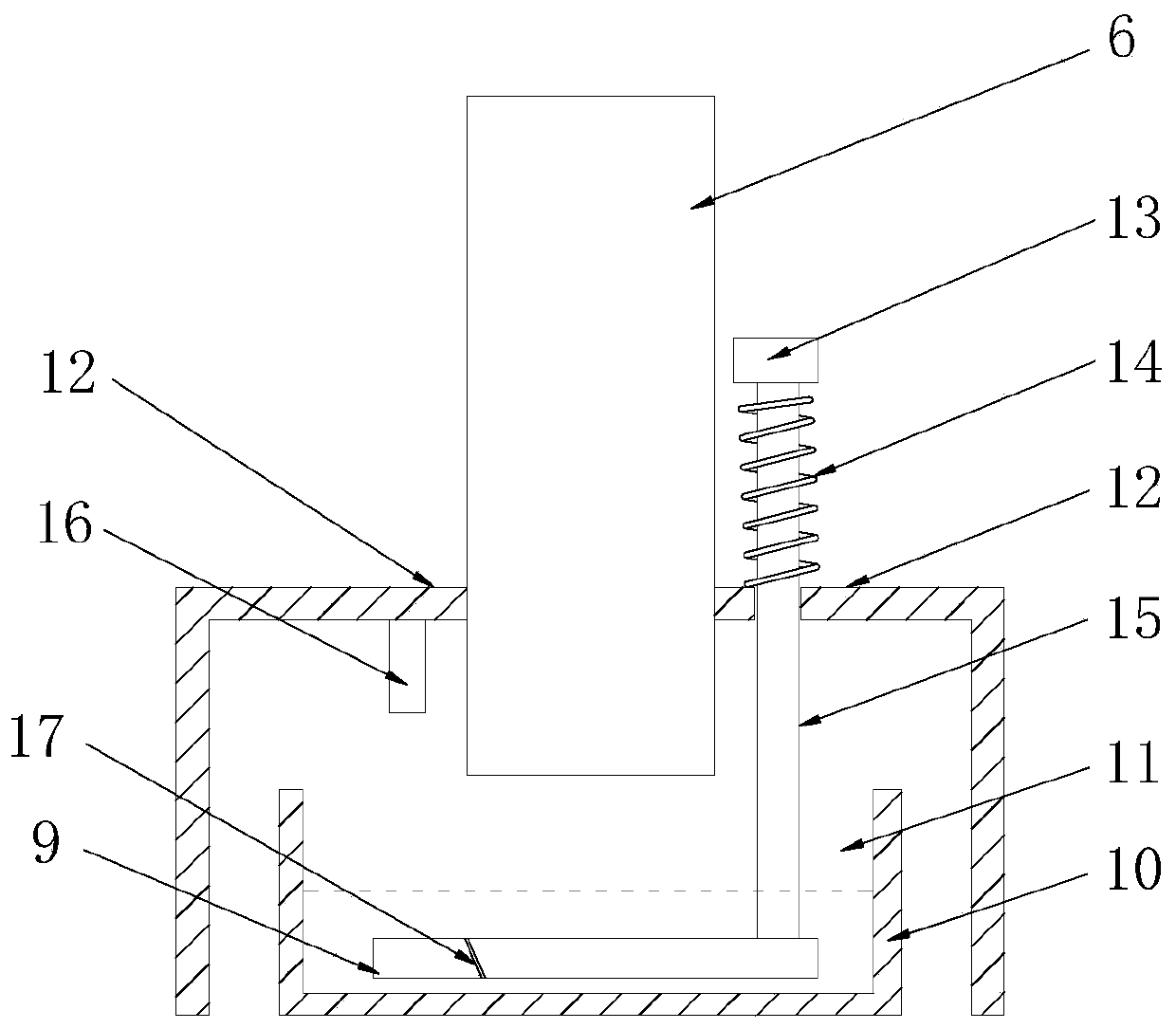

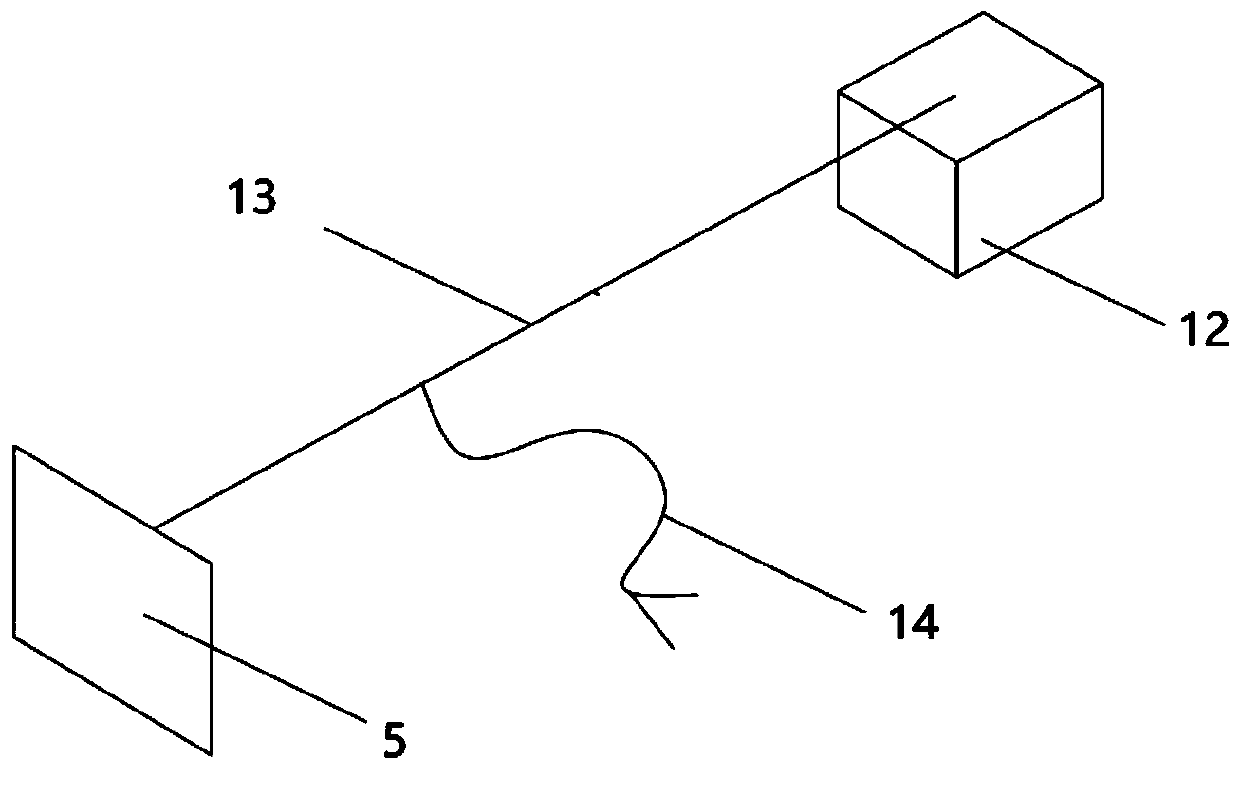

Soap film flow meter with automatic film opening function

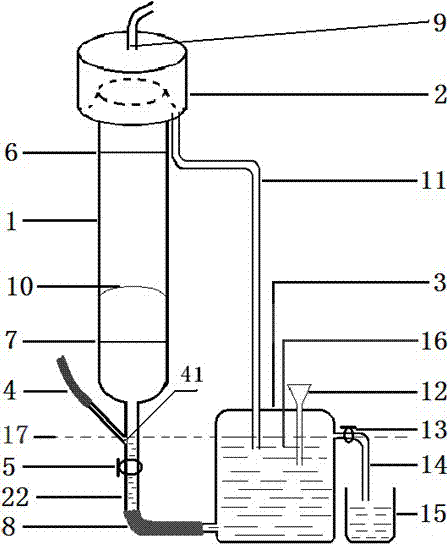

ActiveCN103925957AReduce test errorImprove test efficiencyTesting/calibration apparatusVolume/mass flow measurementCommunicating vesselsSoap film

The invention provides a soap film flow meter with an automatic film opening function. The soap film flow meter comprises a soap film pipe, a soap film producing device and a soap film recycling device. The soap film producing device comprises a liquid soap pipe and an air inlet pipe, and the air inlet pipe is arranged on the upper portion of the liquid soap pipe; the soap film recycling device comprises a soap film recycling cover, a liquid soap recycling pipe and a liquid soap recycling cup, one end of the liquid soap recycling pipe is connected with the liquid soap recycling cover on the top of the soap film pipe, and the other end of the liquid soap recycling pipe extends into the liquid soap recycling cup; the liquid soap recycling cup is filled with liquid soap, the bottom of the liquid soap pipe is connected with a side wall of the bottom of the liquid soap recycling cup, and the liquid level of the liquid soap and the top of an air inlet of the air inlet pipe are positioned at the same altitude. The soap film flow meter has the advantages that an automatic film opening mode can be implemented by the aid of a communicating vessel principle, accordingly, shortcomings of a manual film opening mode can be overcome, and verification errors can be reduced.

Owner:XINJIANG UYGUR AUTONOMOUS REGION INST OF MEASUREMENT & TESTING

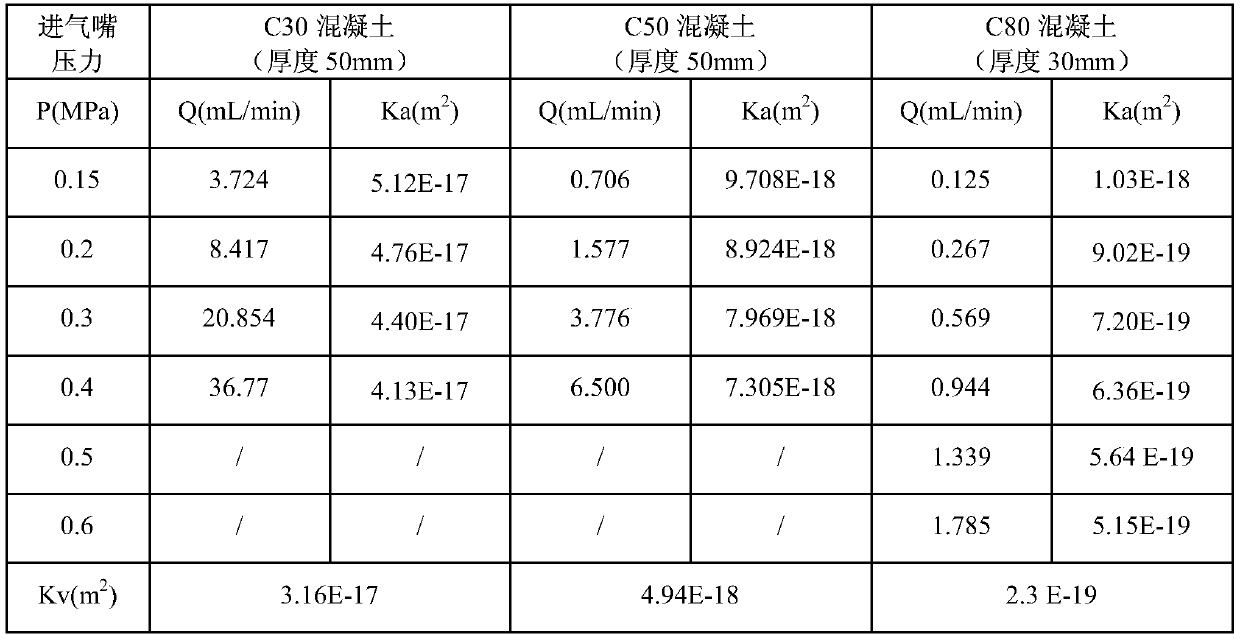

Gas permeability testing method used for high-compactness solid concrete

InactiveCN110702558AImprove air flowBreak through the technical bottleneck of the lack of impermeability performance testing methodsPermeability/surface area analysisEpoxyNitrogen gas

The invention discloses a gas permeability testing method used for high-compactness solid concrete. The method includes: A, forming a cylindrical concrete test piece, and obtaining a round cake test block by cutting after curing, wherein round cake thickness is 30 mm; B, drying the round cake, placing the same in a constant temperature and humidity environment until constant weight of the test block is achieved, coating a side surface of the round cake with epoxy resin, and carrying out drying; C, assembling a gas permeation unit, and connecting a gas permeation testing device gas path, wherein the unit includes a base seat, a steel sleeve of a middle section and a top cover of an upper part, the round cake-shaped concrete test block is placed in the steel sleeve, a silicone sleeve and aninflatable rubber oil bag are sequentially arranged from an inside to an outside between the test block and the steel sleeve, a gas input mouth is arranged at the base seat to connect a high-pressurenitrogen source, a gas output mouth is arranged at the top cover to connect a soap film flow meter, the inflatable rubber oil bag elastically seals a side edge of the round cake concrete test block through squeezing the silicone sleeve after inflation, inflation pressure of the inflatable rubber oil bag is 0.8 MPa, an inner diameter of a glass tube of the soap film flow meter is 3 mm, and a rangeof the soap film flow meter is 0.01 ml / min-10 ml / min; and D, carrying out gas permeability testing of the concrete test block and result calculation.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

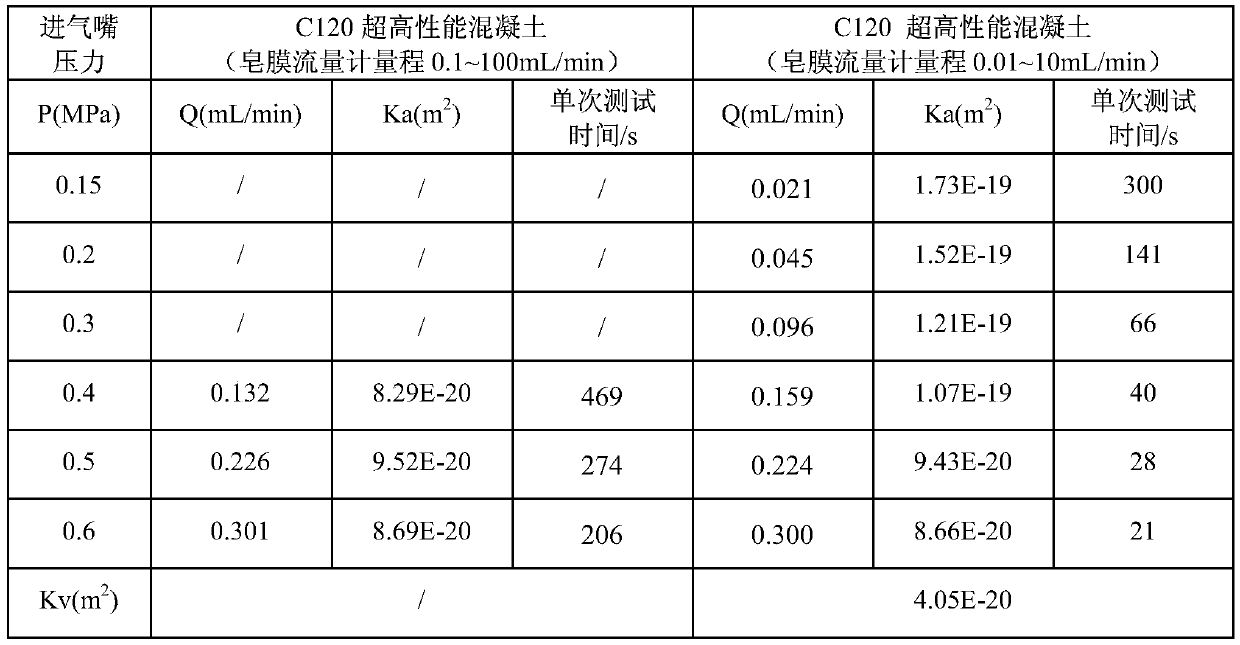

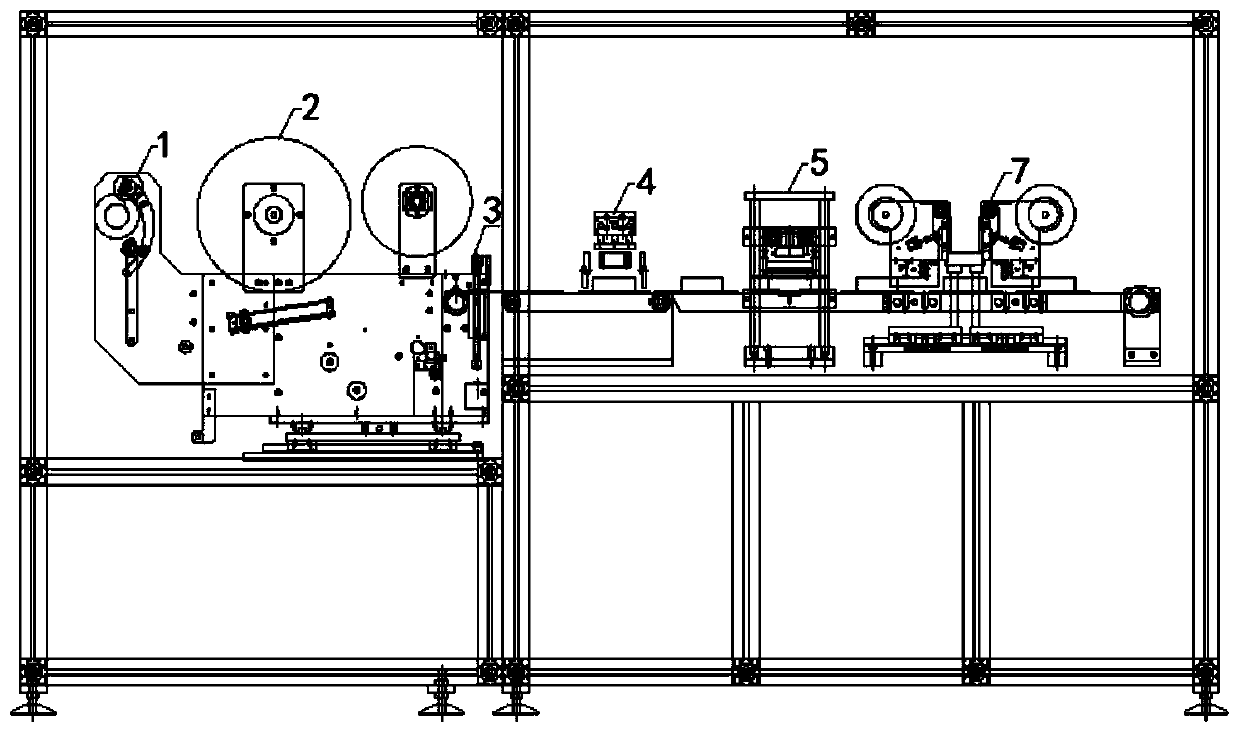

Automatic soap film paper packaging system

PendingCN111169709AAvoid influenceAvoid deformationWrapping material feeding apparatusWrapper folding/bending apparatusEngineeringSoap film

The invention relates to the field of soap packaging, in particular to an automatic soap film paper packaging system. The automatic soap film paper packaging system is characterized by comprising a film releasing mechanism, a double-faced adhesive tape pasting mechanism, a film cutting off mechanism, a soap feeding mechanism, a primary corner folding packaging mechanism, a secondary corner foldingpackaging mechanism and a single-faced adhesive tape pasting mechanism, film paper output by the film releasing mechanism is bonded with a double-faced adhesive tape on the double-faced adhesive tapepasting mechanism, and then is cut off through the film cutting off mechanism, soap is placed in through the soap feeding mechanism, the portion, on the periphery of the soap, of the film paper is folded in a surrounding mode through the primary corner folding packaging mechanism, then the portions, at the two ends of the soap, of the film paper are folded through the secondary corner folding packaging mechanism, and then a single-faced adhesive tape is pasted through the single-faced adhesive tape pasting mechanism to complete packaging. After the scheme is adopted, the soap can be preventedfrom being influenced by heat sealing during packaging.

Owner:绍兴市全特电子设备有限公司

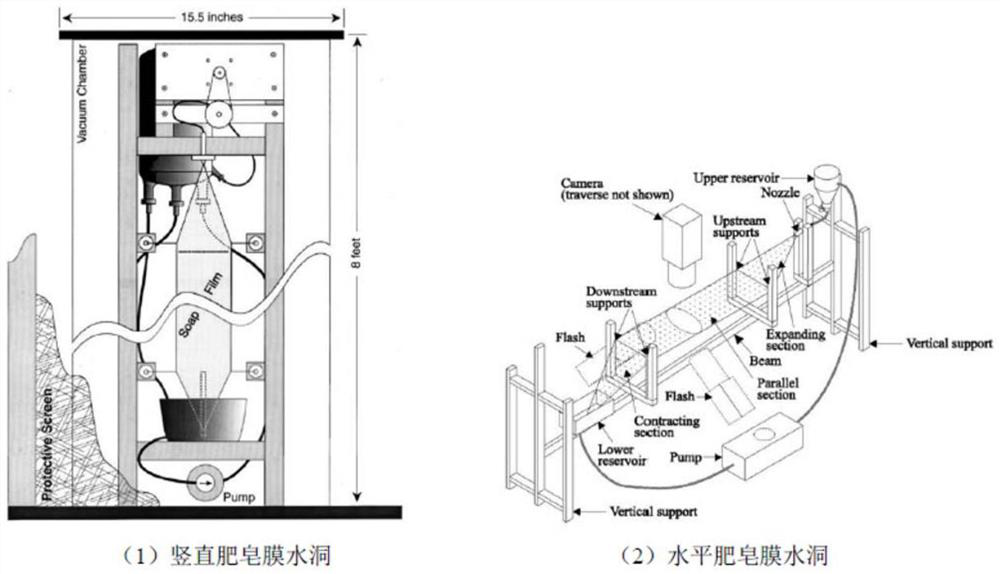

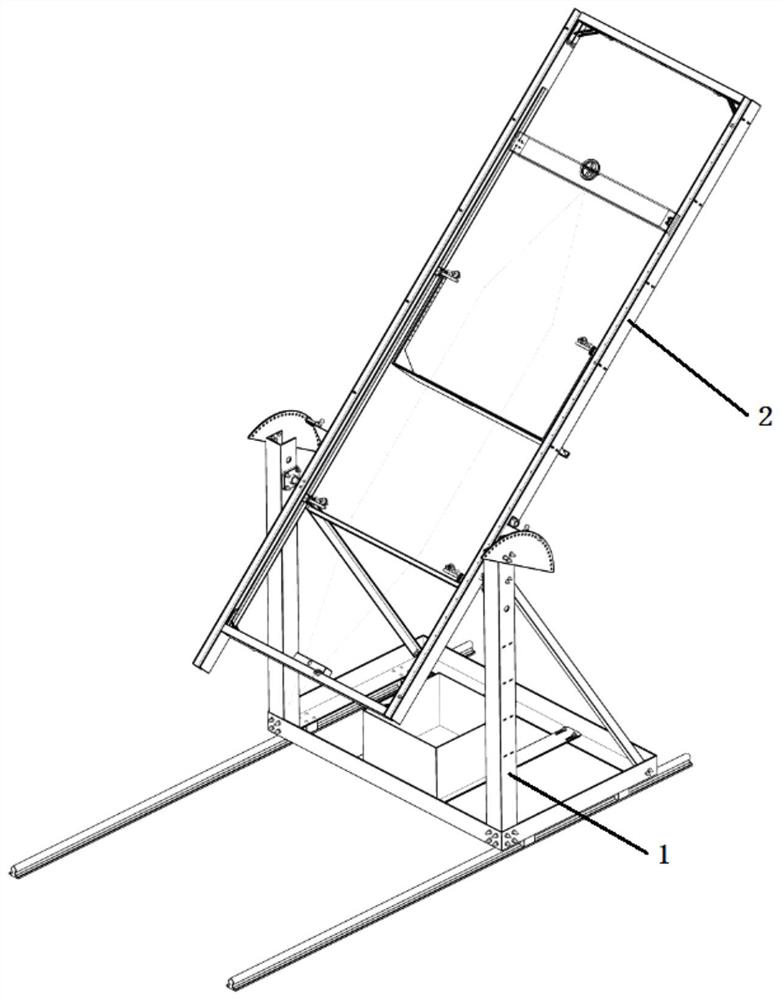

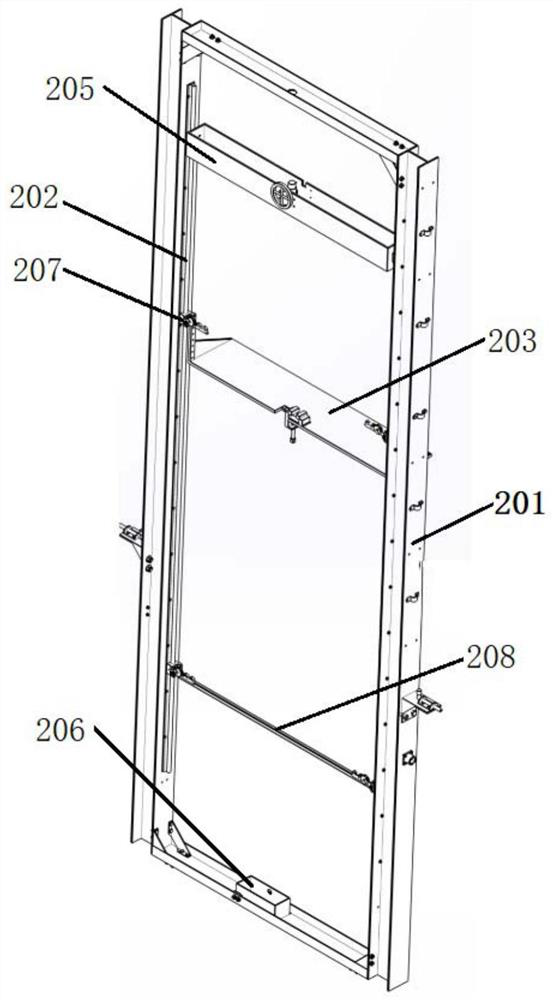

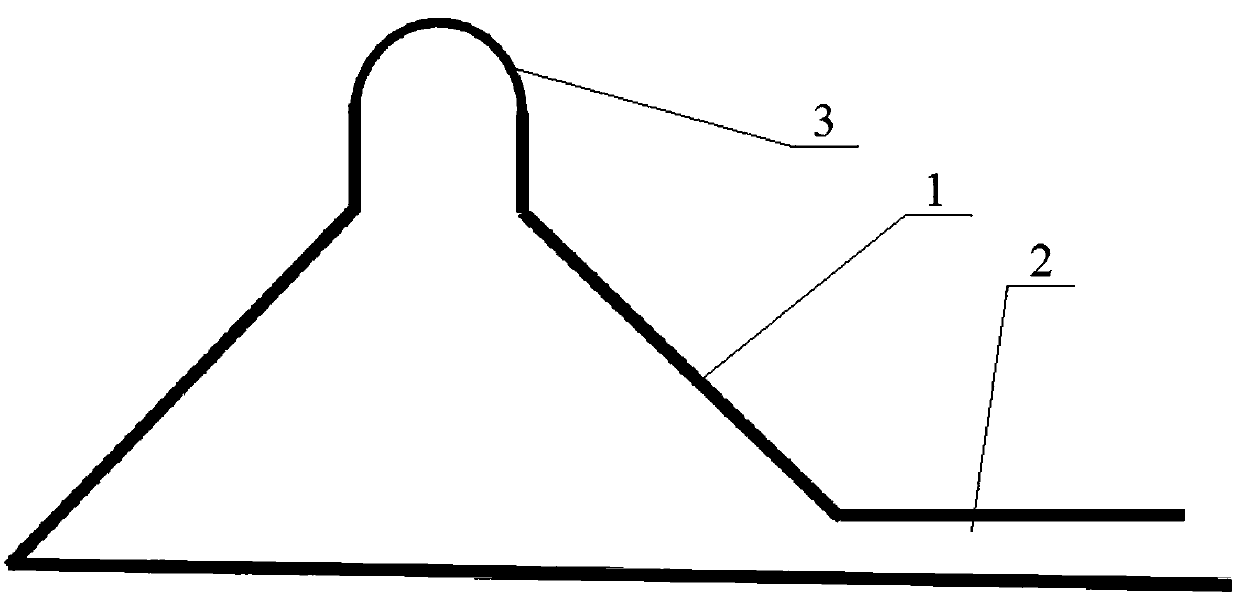

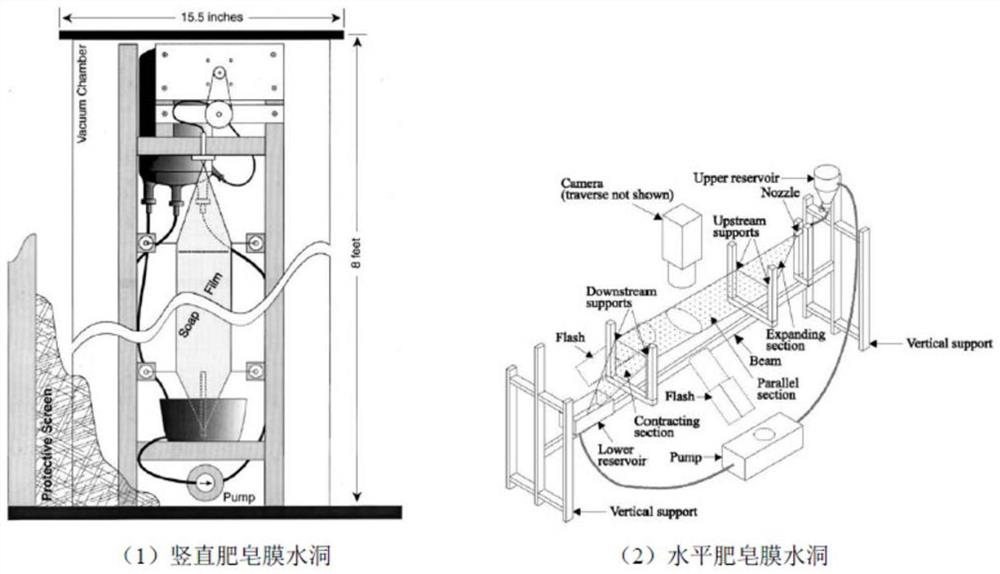

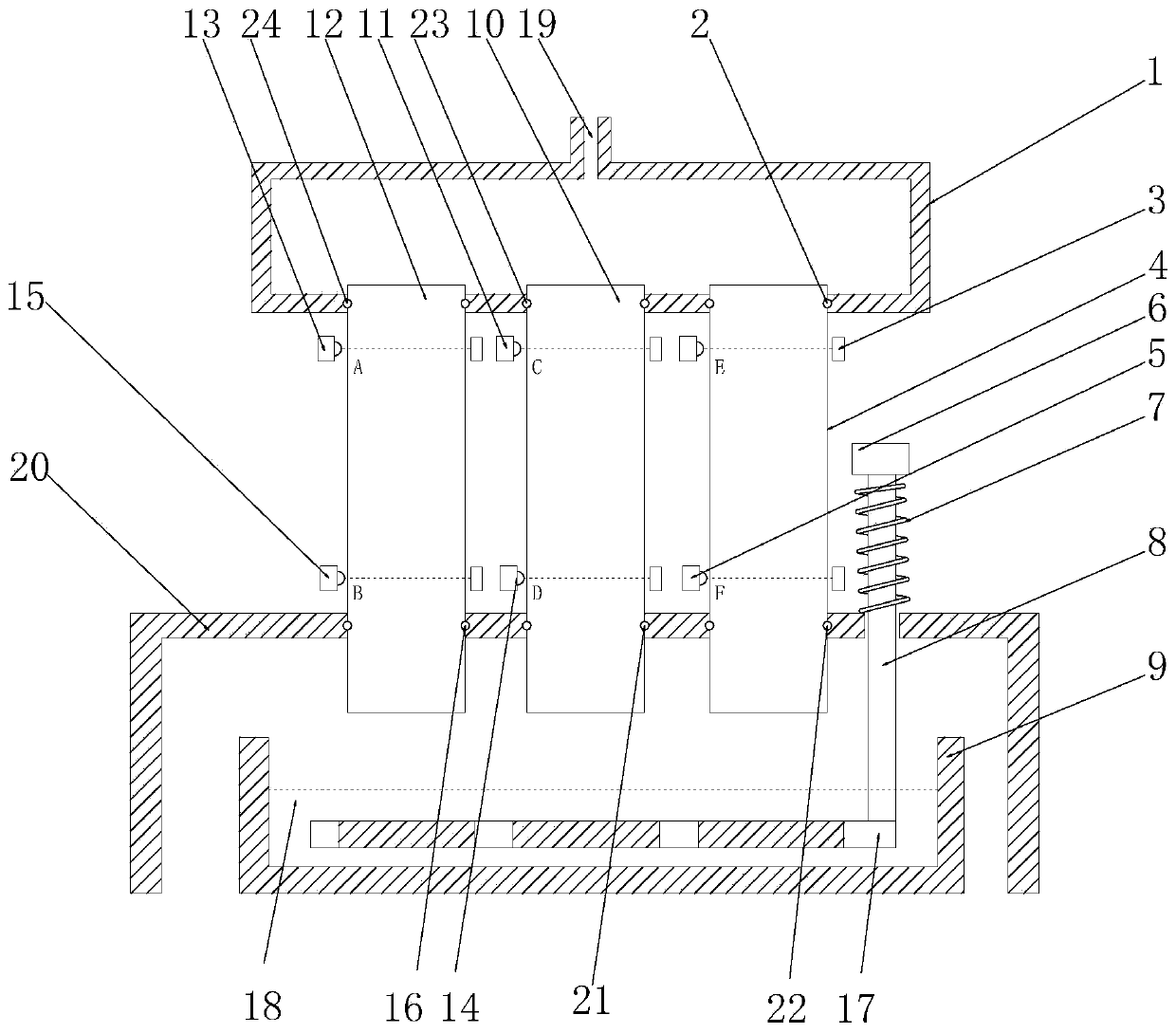

Soap film water tunnel test device

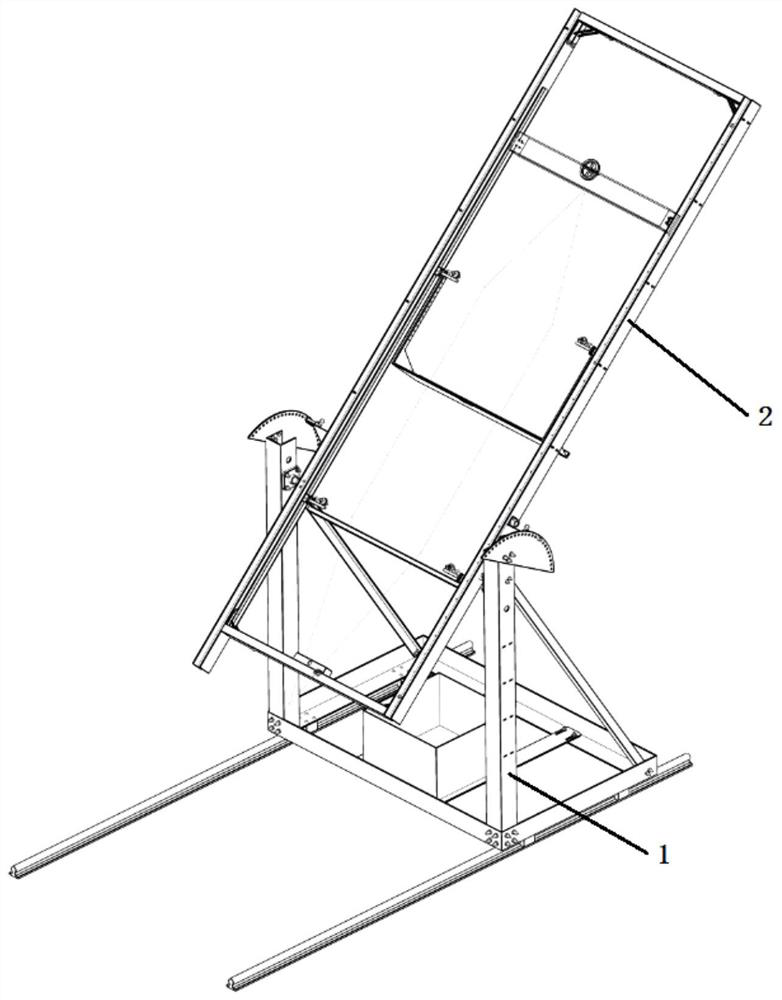

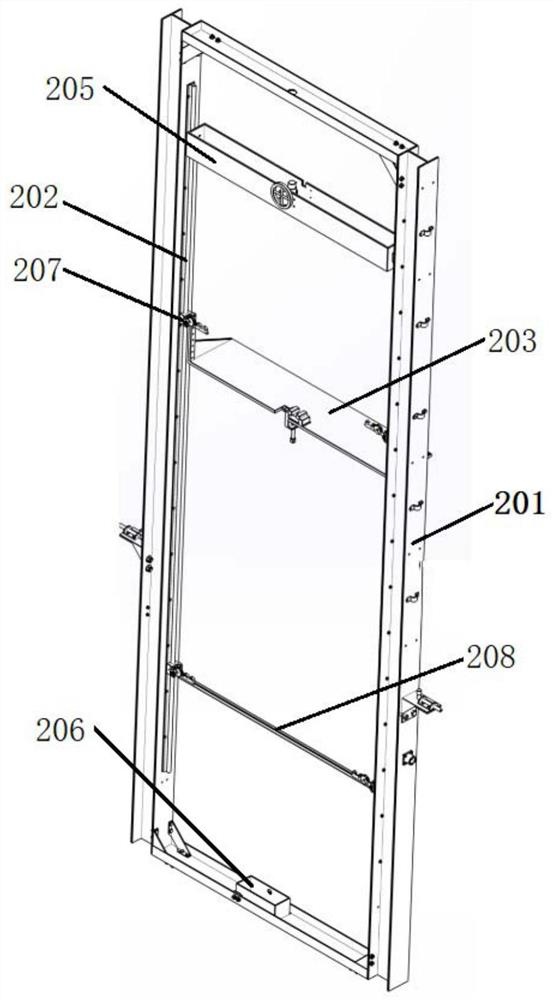

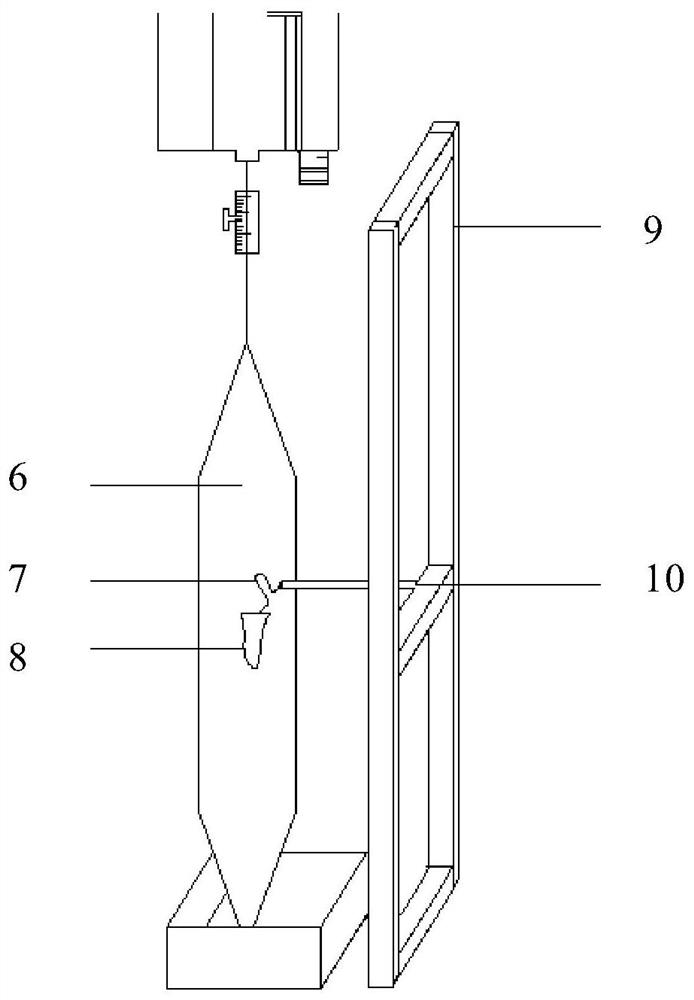

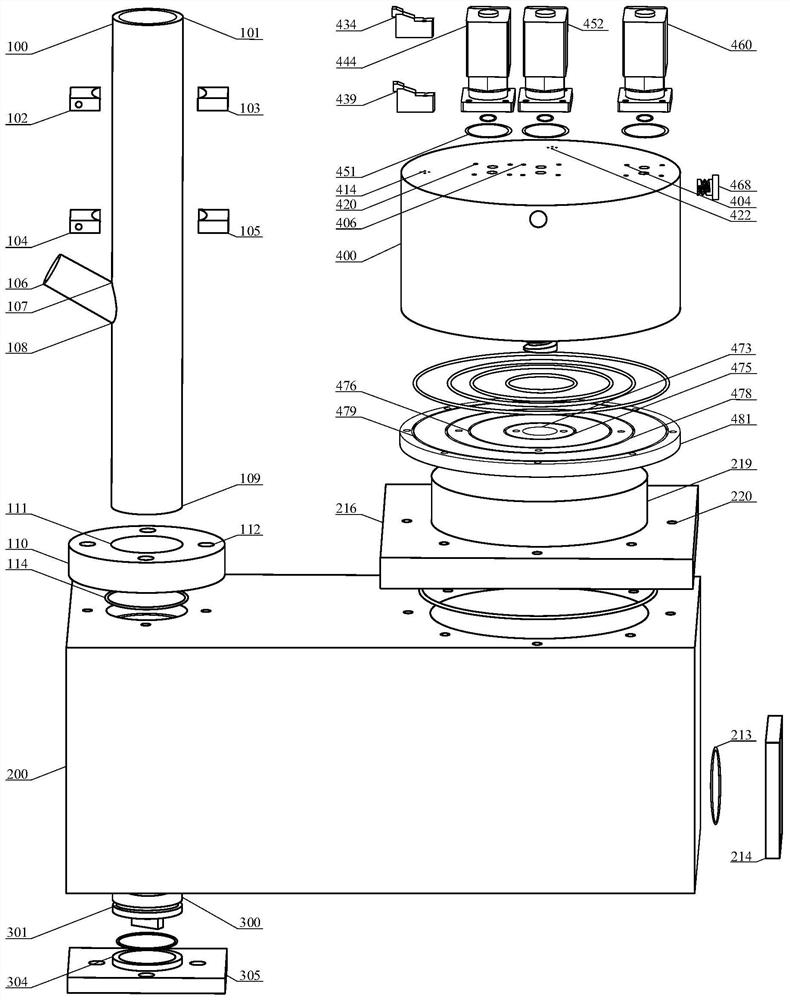

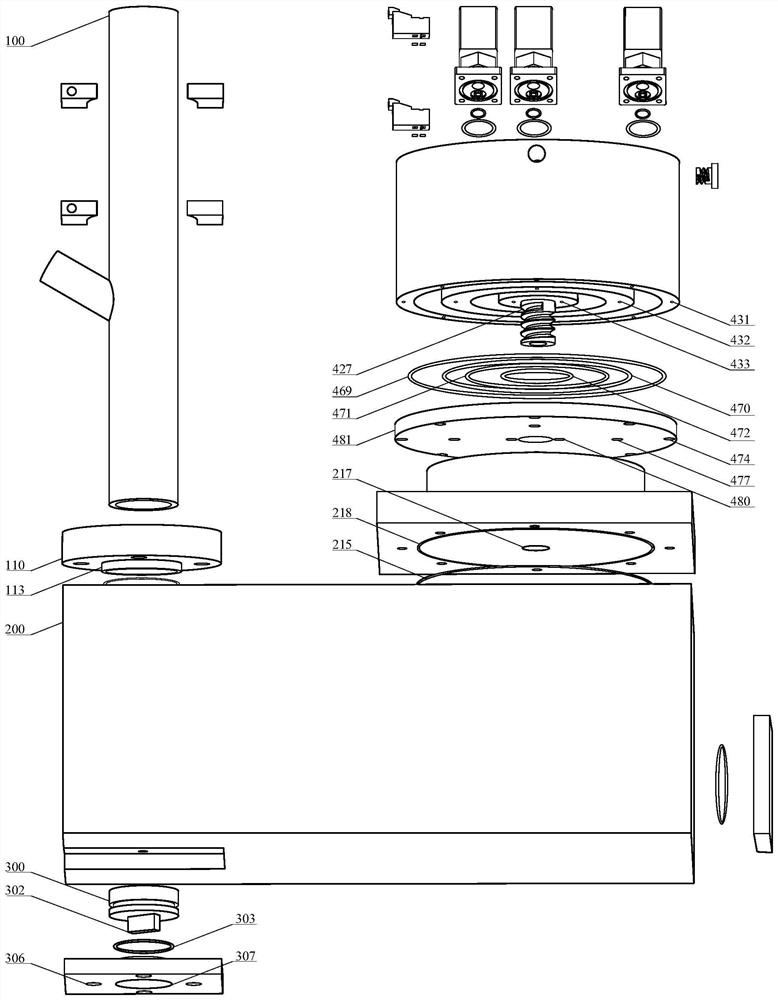

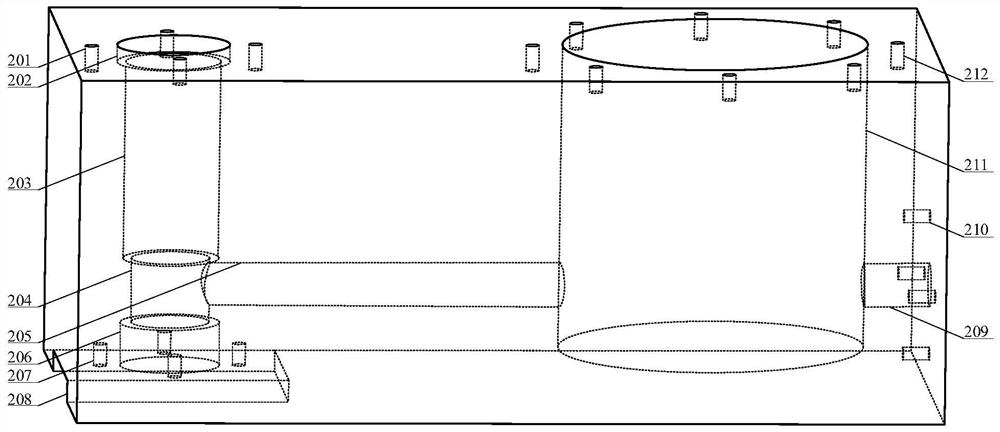

ActiveCN112362300AChange widthChange test angleHydrodynamic testingStructural engineeringTest requirements

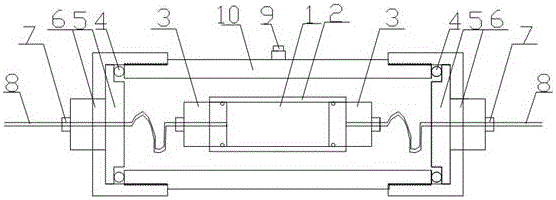

The invention discloses a soap film water tunnel test device, can realize effective control of soap film flow, and can adjust test related parameters according to test requirements. The soap film water tunnel test device comprises an outer frame, an inner frame and a position locking mechanism; the left end and the right end of the inner frame are supported on the outer frame through bearings andcan rotate around the axes of the bearings to change the rotating angle of the inner frame. The position locking mechanism is used for locking the position of the inner frame after the inner frame rotates to a set angle; the inner frame comprises a bracket, a bracket guide rail, a silk thread, an upper water tank, a lower water tank and a mold table; the mold table is used for fixing a mold required by a test; by adopting the test device, the length and the position of the test area can be adjusted according to test requirements, the test area width (soap film width) is changed, and the test angle is changed; therefore, two-dimensional water tunnels with different parameters are constructed to adapt to different models; and the flow velocity of the flow field can be changed.

Owner:北京启航凯博科技有限公司

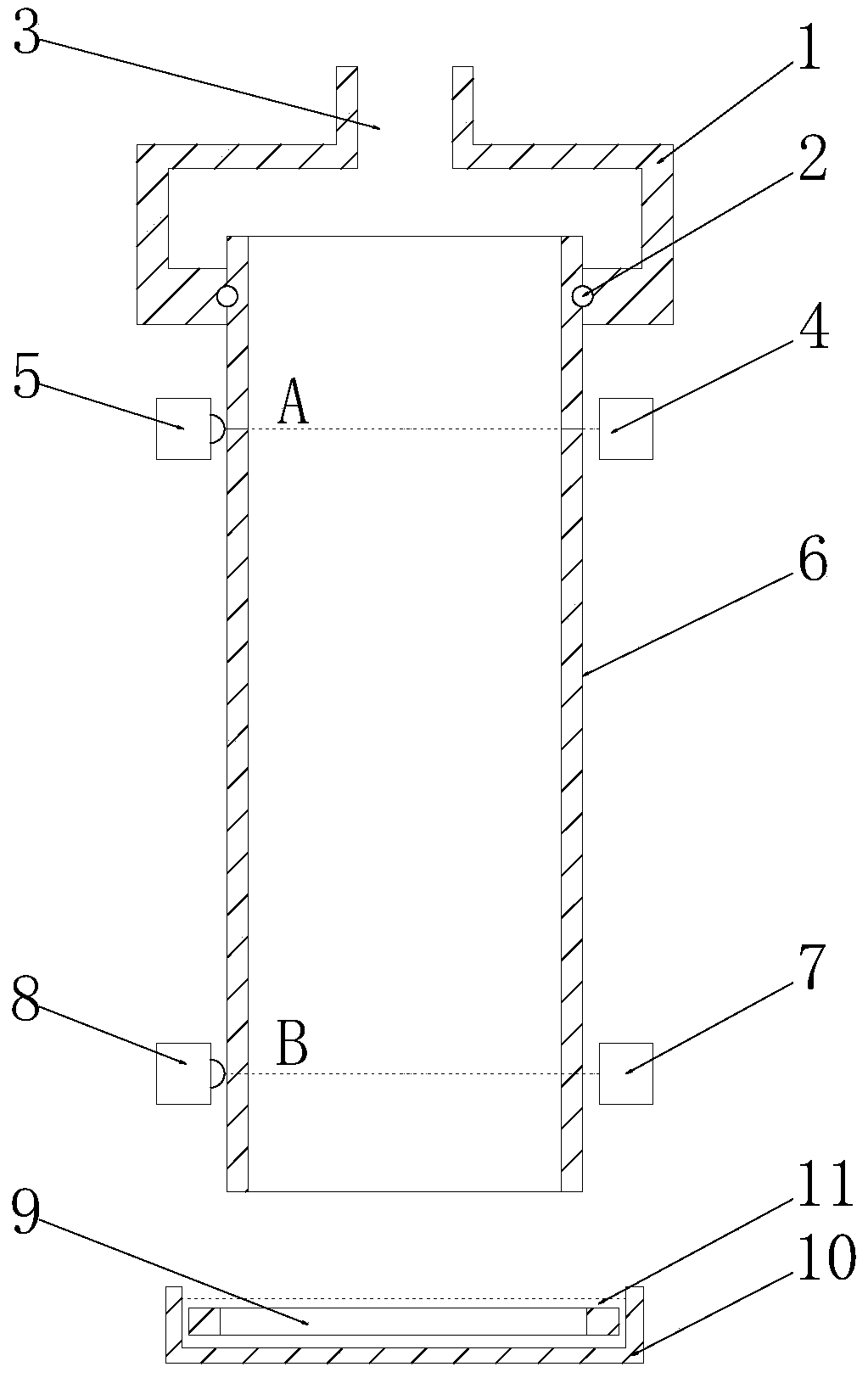

Miniature sample-based biological reef rock conventional physical property tester device

InactiveCN106324217ARealize full physical property measurementFlexible loading and unloading designEarth material testingPermeability/surface area analysisPorosityMeasurement device

The invention discloses a miniature sample-based biological reef rock conventional physical property tester device. The tester device comprises a miniature sample-based biological reef rock conventional physical property tester, a penetration rate testing device, a porosity measurement device, a booster pump, a soap film flowmeter, a pressure gauge and a switch, wherein the miniature sample-based biological reef rock conventional physical property tester comprises a cylinder body, a rubber sleeve, rubber sleeve end plugs, a cylinder body end cap, a cylinder body sealing cover and a sealing component; the cylinder body is of a hollow structure, the rubber sleeve and the rubber sleeve end plug are arranged in the cylinder body, and rock core samples are placed in the rubber sleeve; and the rubber sleeve end plugs are embedded into two ends of the rubber sleeve and are in direct contact with the rock core samples. According to the tester device, the different small-diameter rock cores can be clamped, and the normal operation of physical property testing can be guaranteed.

Owner:QINGDAO INST OF MARINE GEOLOGY +1

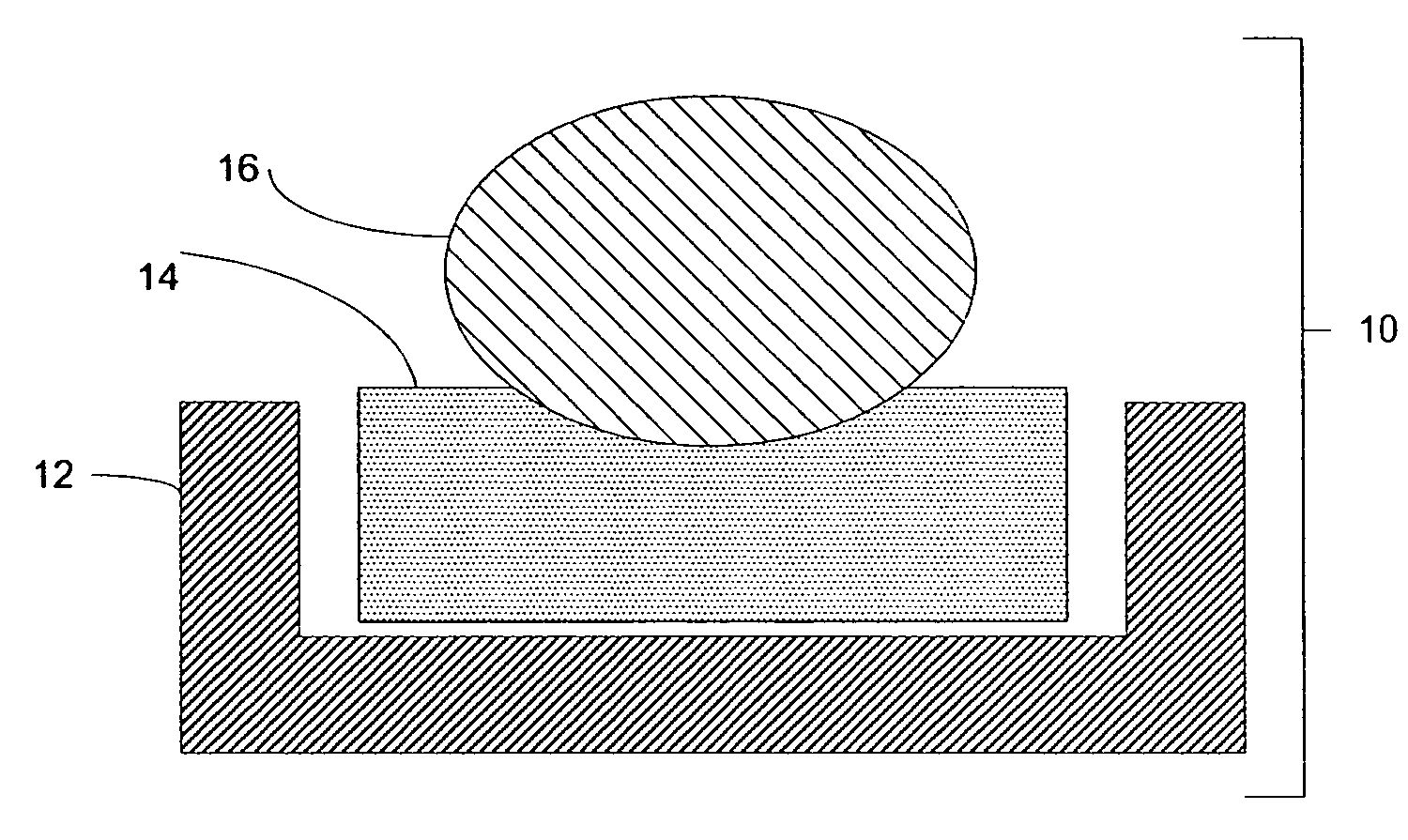

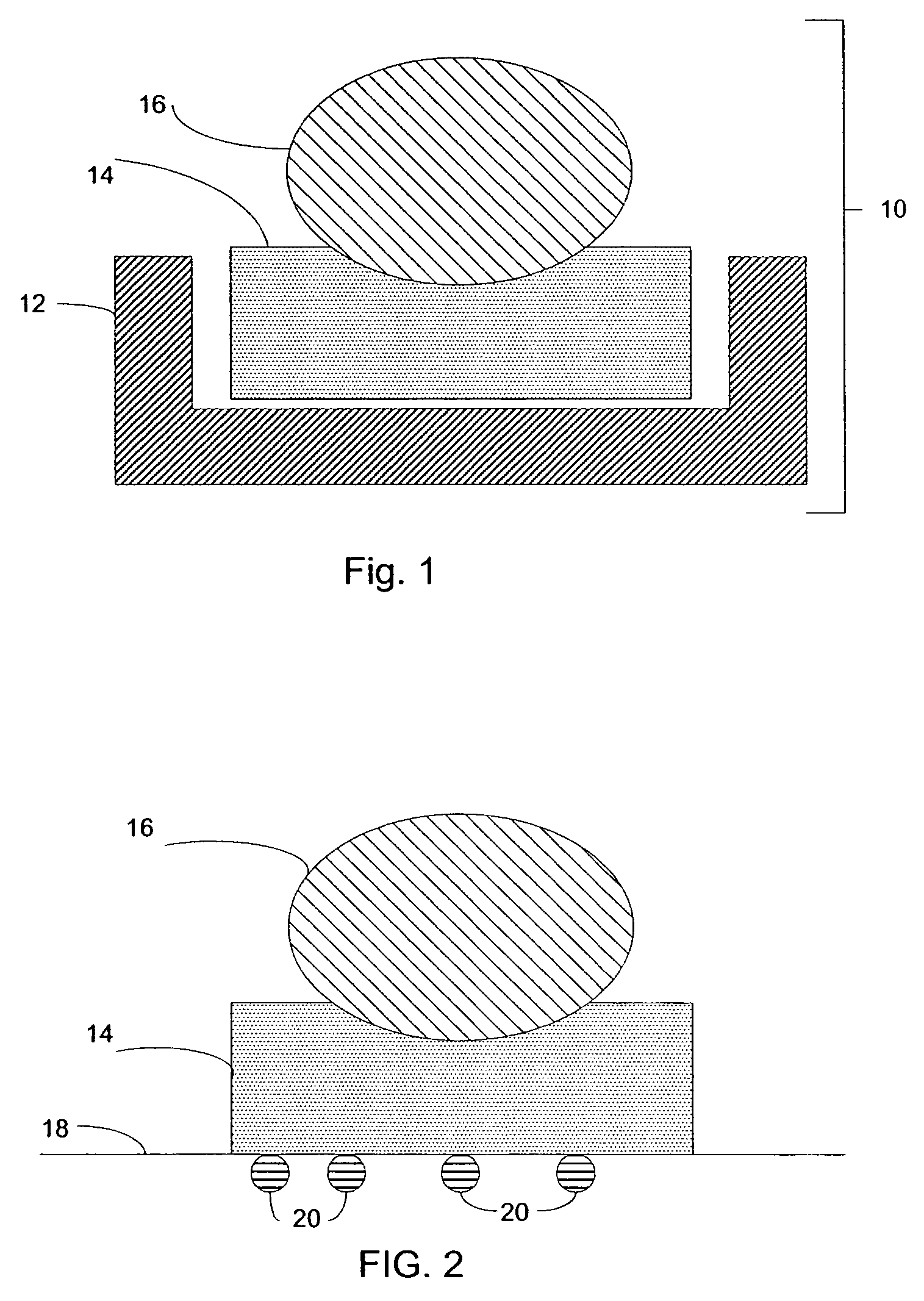

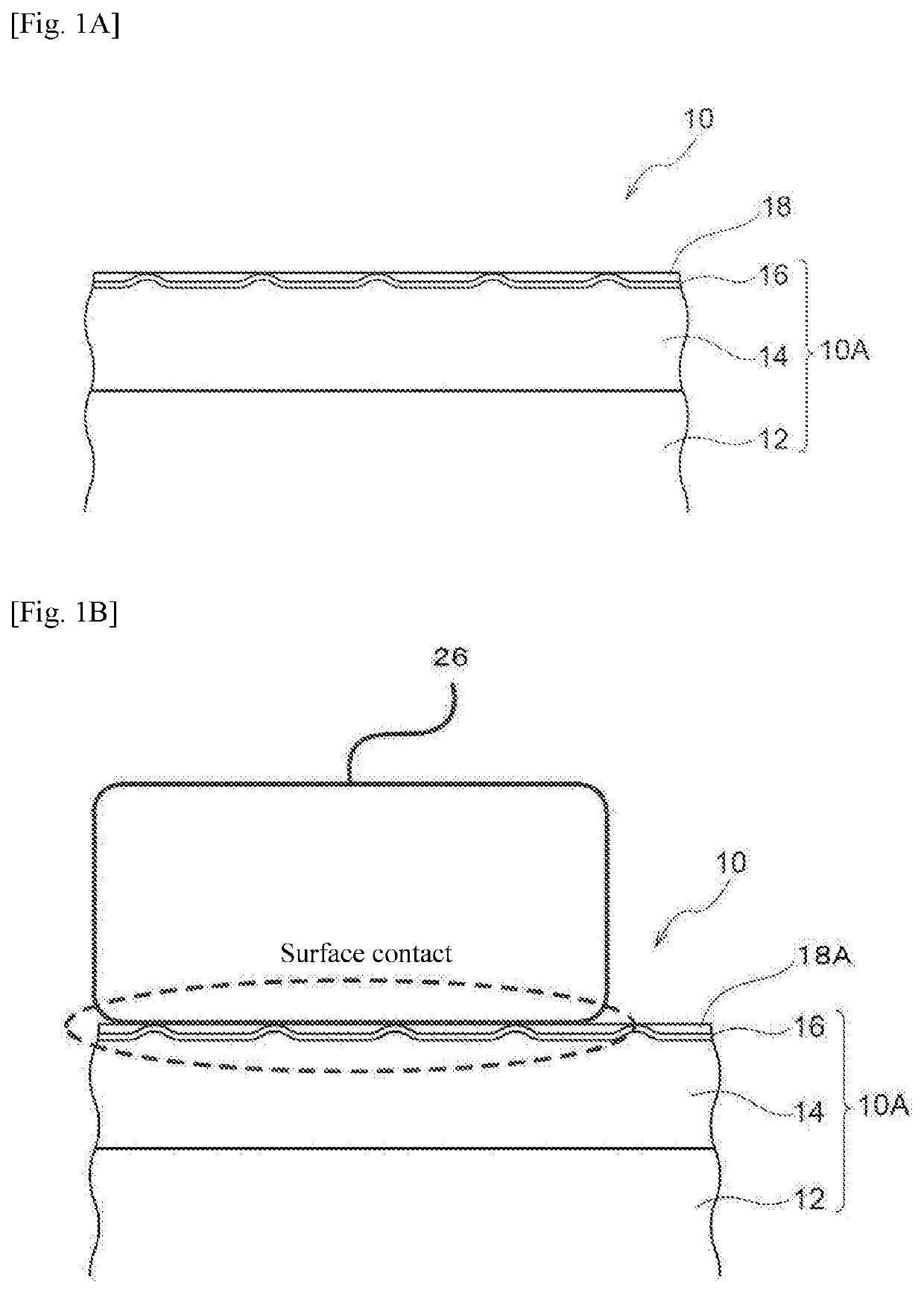

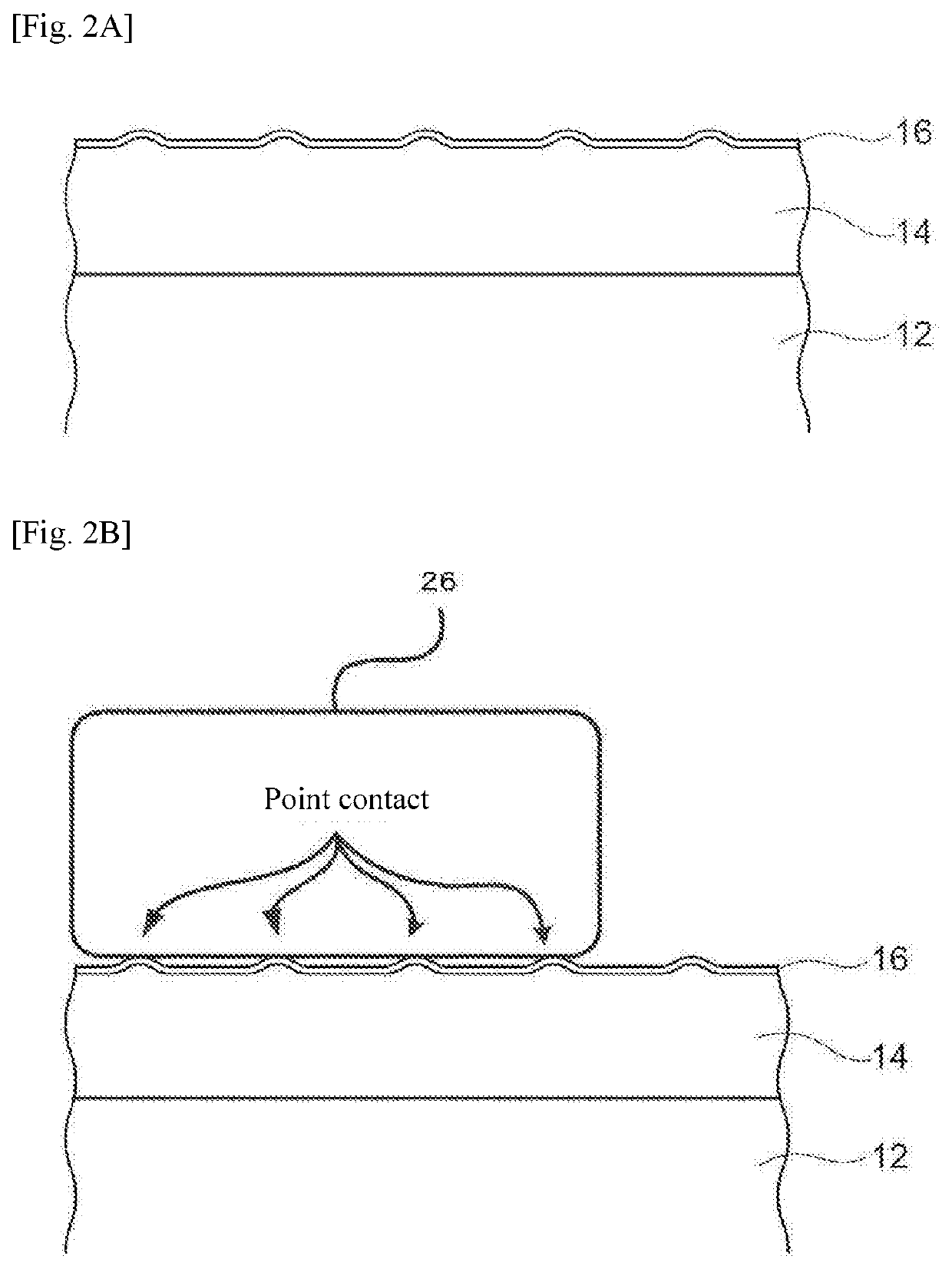

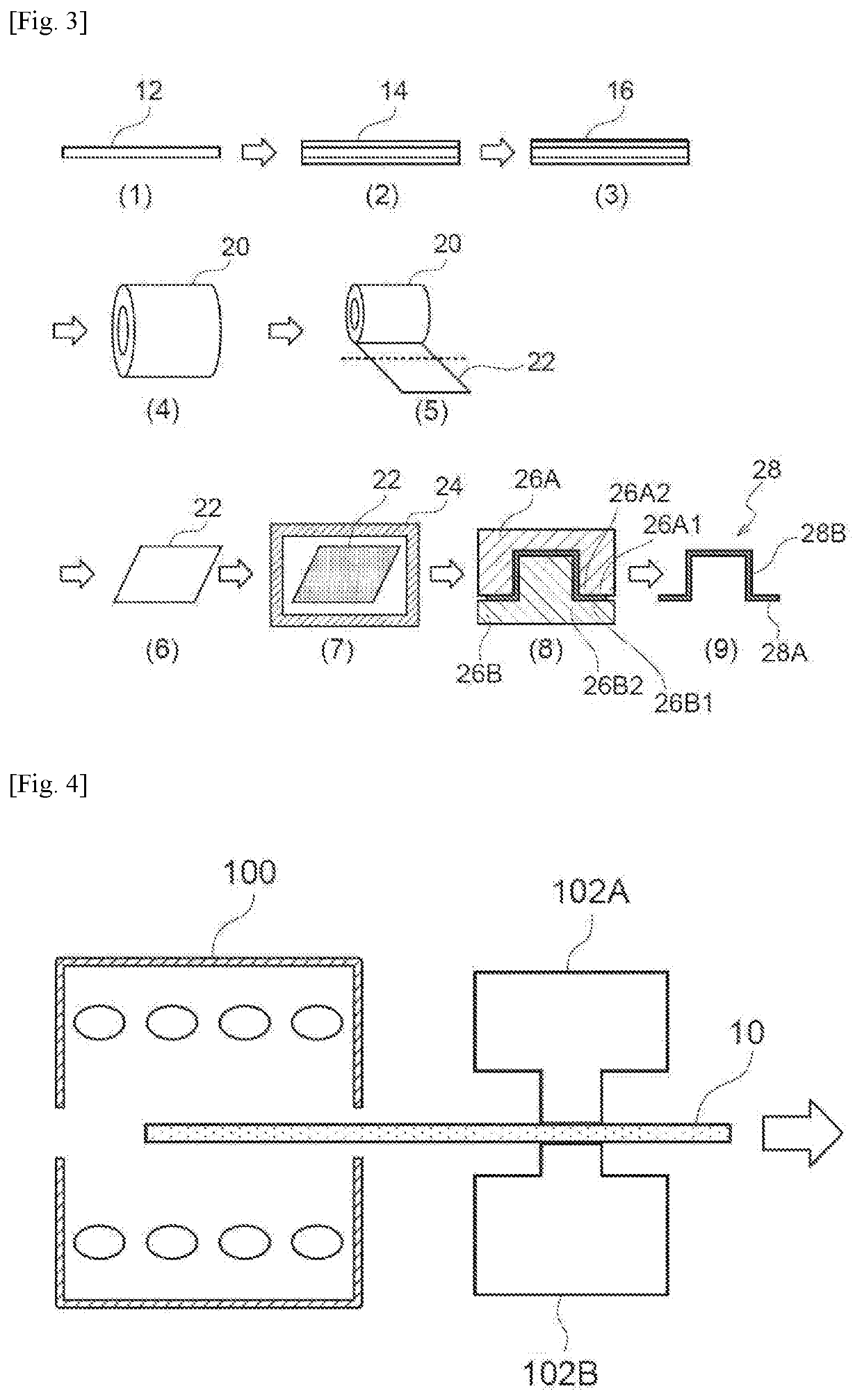

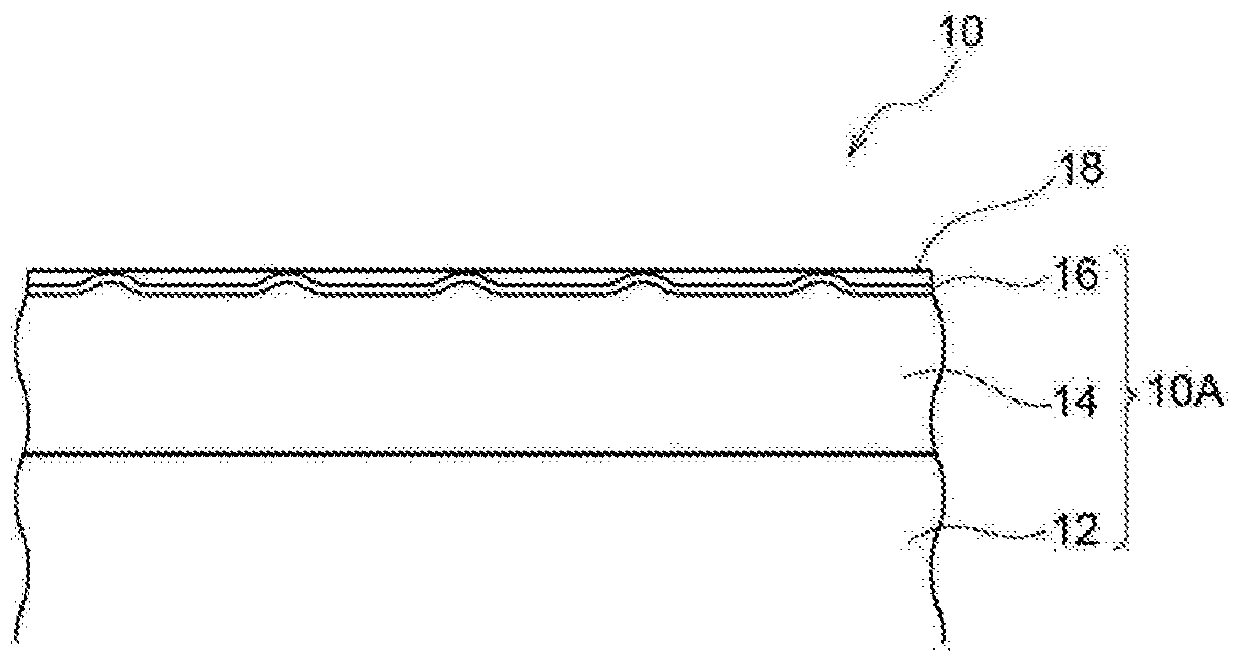

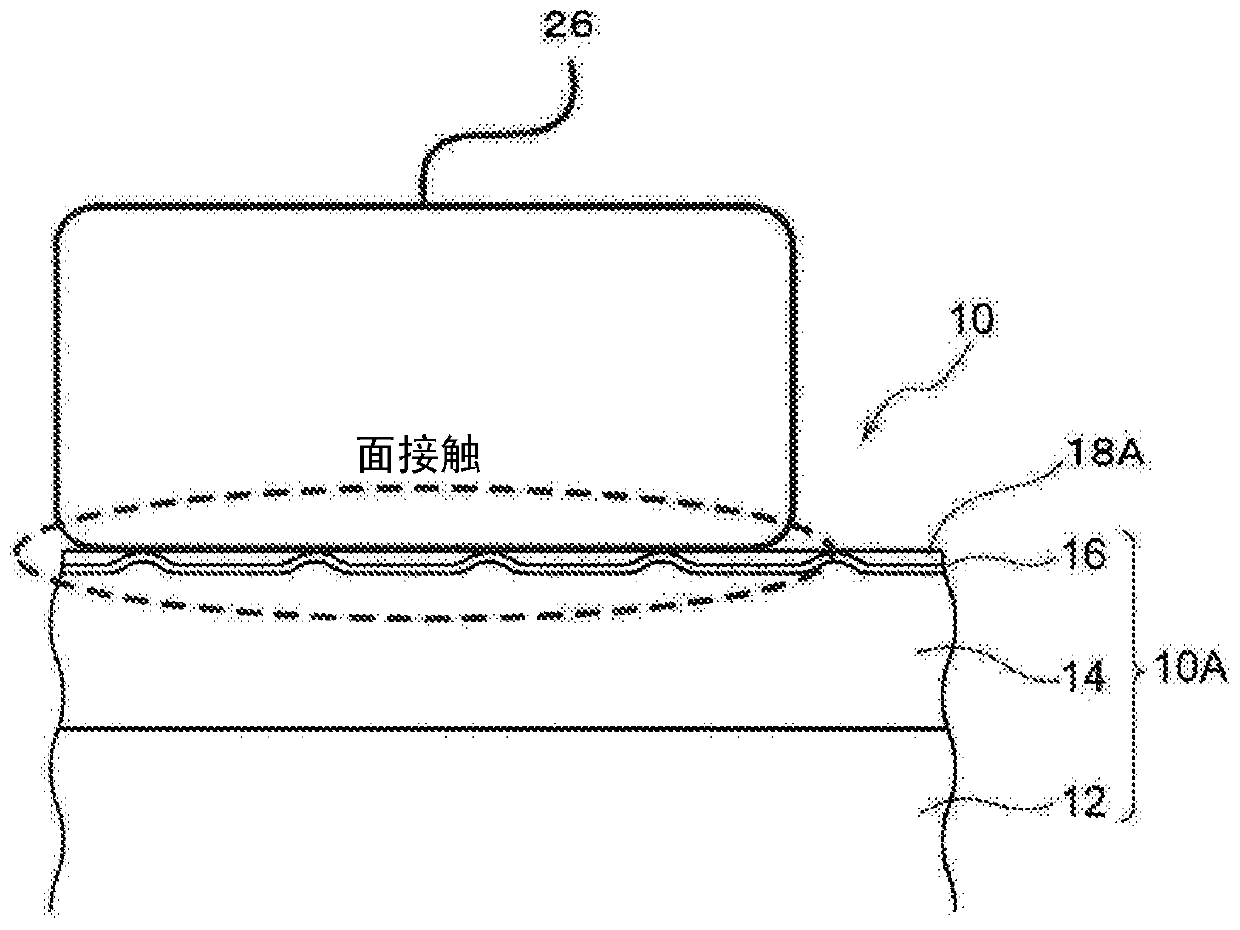

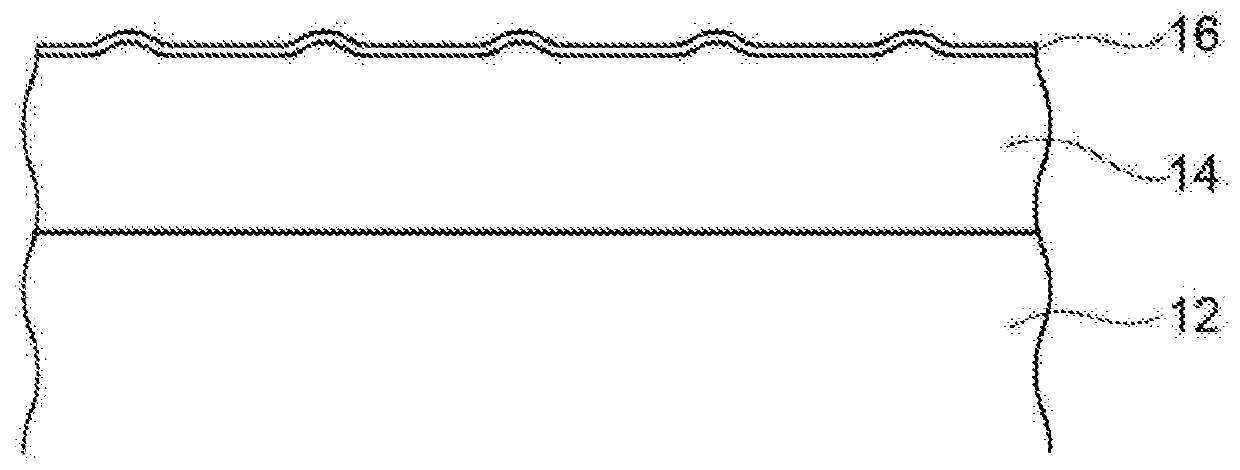

Plated steel sheet for hot stamping, method of manufacturing plated steel sheet for hot stamping, method of manufacturing hot-stamped component, and method of manufacturing vehicle

Provided are a plated steel sheet for hot stamping including: a plated steel sheet body including a steel sheet and an aluminum plating layer provided on one side or both sides of the steel sheet; and a zinc-based metal soap film provided on a surface of the plated steel sheet body on a side of the aluminum plating layer and having an adhesion amount of from 7.1 to 19.8 g / m2 based on a Zn amount (when, in the plated steel sheet body, a zinc oxide film is on the surface of an aluminum plating layer, the total adhesion amount of the zinc oxide film and the zinc-based metal soap film is from 7.1 to 19.8 g / m2 based on a Zn amount.), and a method of manufacturing such a sheet. Also provided are a method of manufacturing a hot-stamped component using the plated steel sheet for hot stamping, and a method of manufacturing a vehicle using a stamped component manufactured by a method of manufacturing a hot-stamped component.

Owner:NIPPON STEEL CORP

Electronic automatic verification device for soap film flow

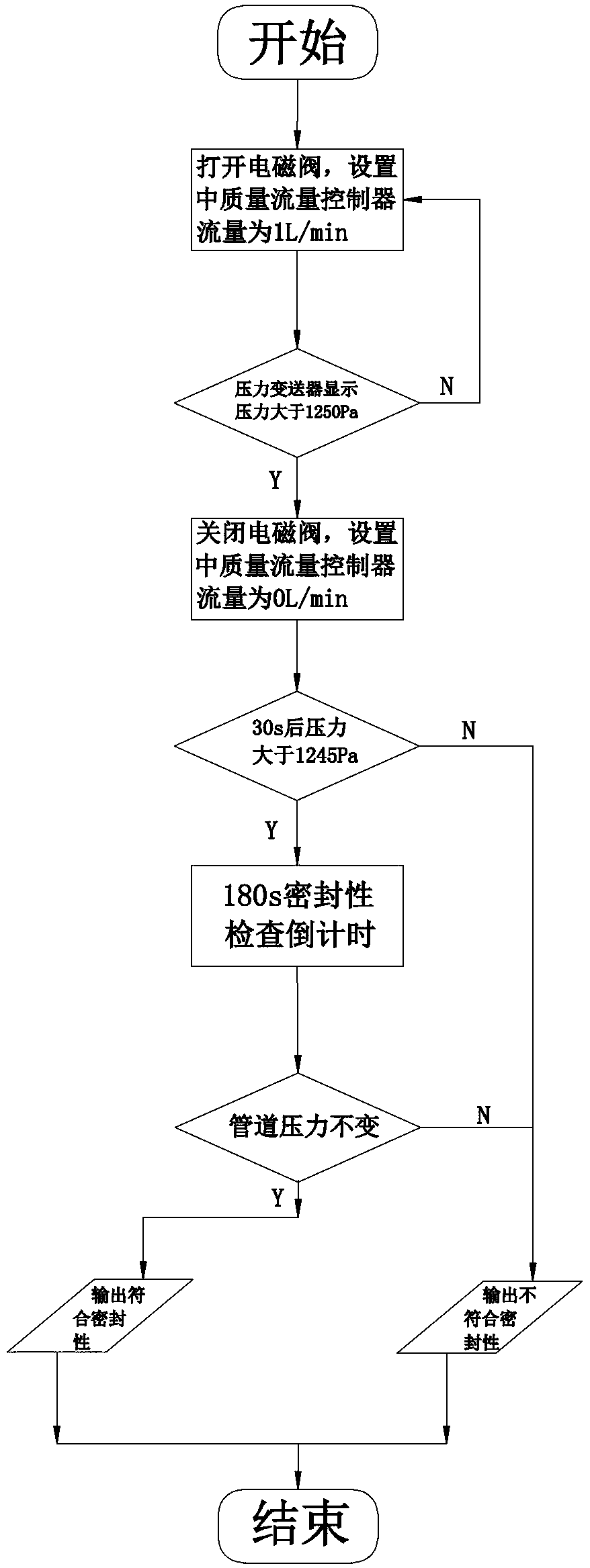

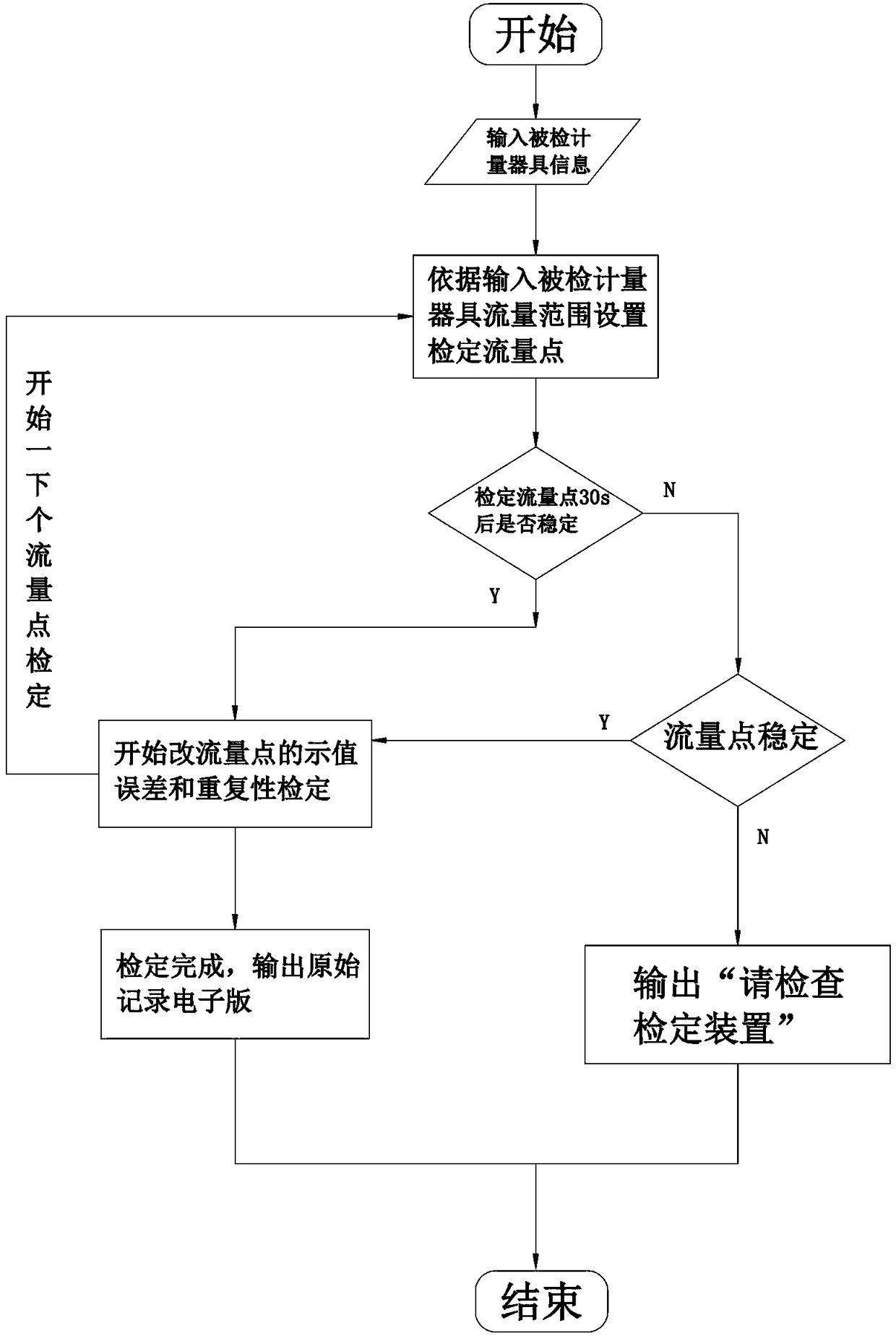

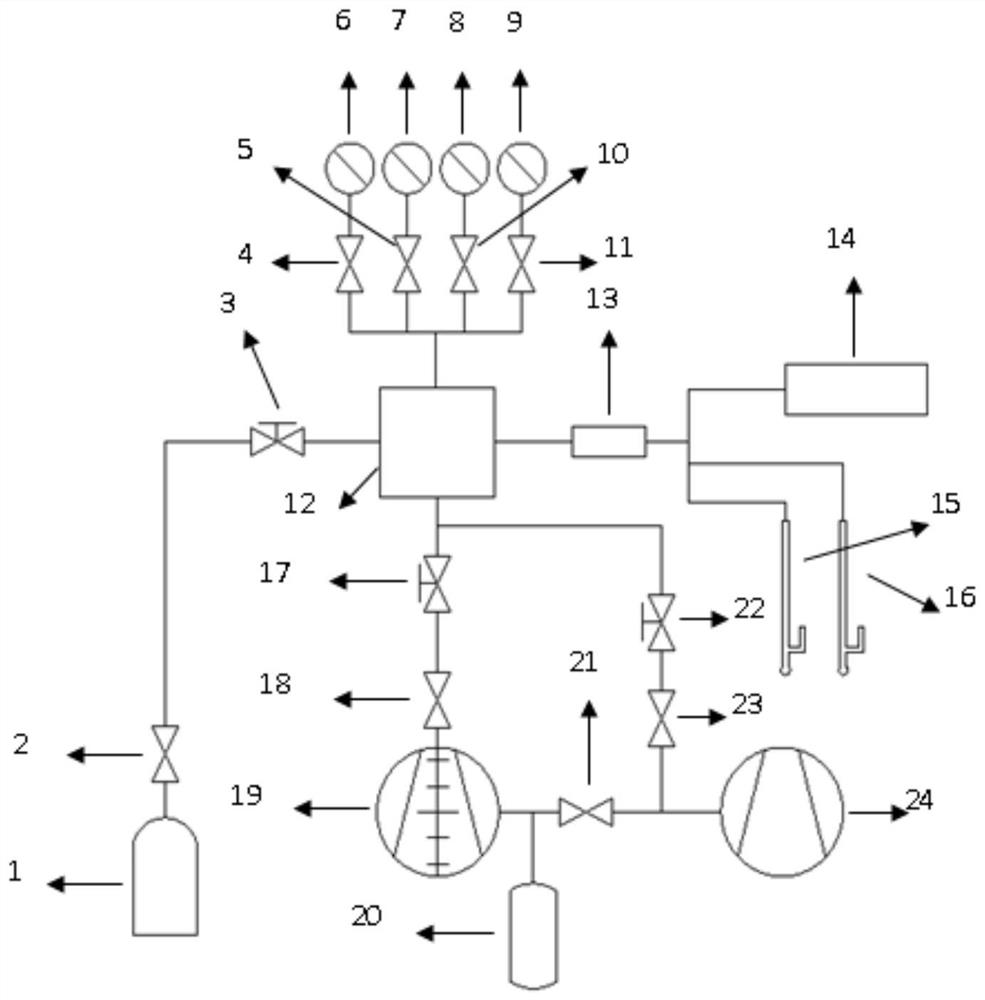

PendingCN108955839AReduce use costAutomatic Verification ImplementationTesting/calibration for volume flowVapor–liquid separatorSoftware system

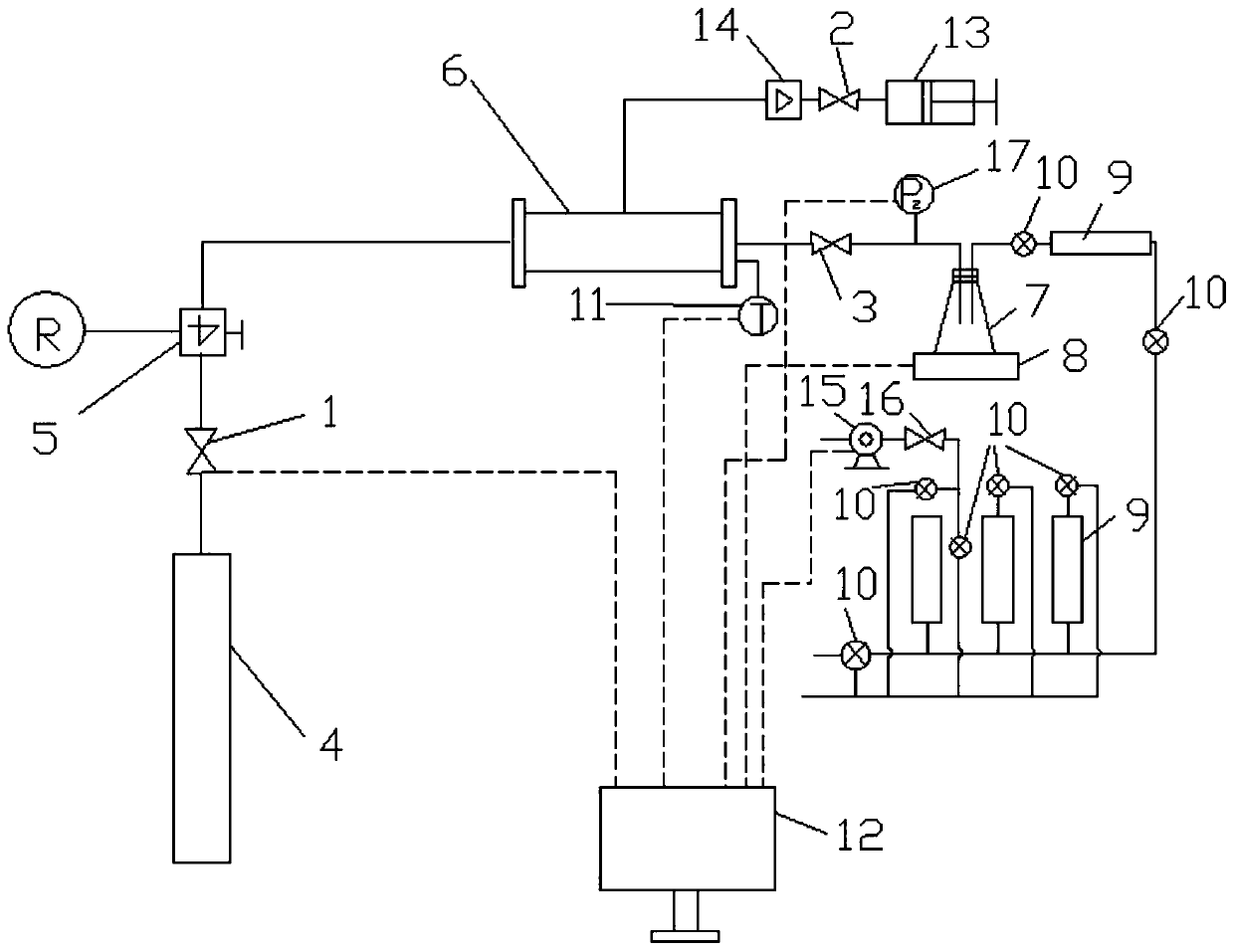

The invention relates to an electronic automatic verification device for soap film flow. The problem that output of an existing verification device is unstable and an original record of detection cannot be automatically generated is effectively solved. According to the technical scheme, the device includes an automatic stabilization gas source system, a pipeline system, a data acquisition and control system, and an upper computer verification software system; the automatic stabilization gas source system includes a gas source, one end of the automatic stabilization gas source system is communicated with a gas-liquid separator, the other end of the gas-liquid separator is communicated with a precise pressure regulating valve, the other end of the precise pressure regulating valve is communicated with a solenoid valve, the other end of the solenoid valve are communicated with three mass flow controllers with different flow ranges respectively, and the three mass flow controllers with different flow ranges refer to the small mass flow controller, the middle mass flow controller and a big mass flow controller. The other ends of the three mass flow controllers are communicated with buffering tanks with different volumes respectively, and the three buffering tanks are communicated with an air outlet. The output of the device is stable and the practicability is high.

Owner:HENAN PROVINCE INST OF METROLOGY

A Method for Continuous Detection of Physical Parameters of Tight Rocks

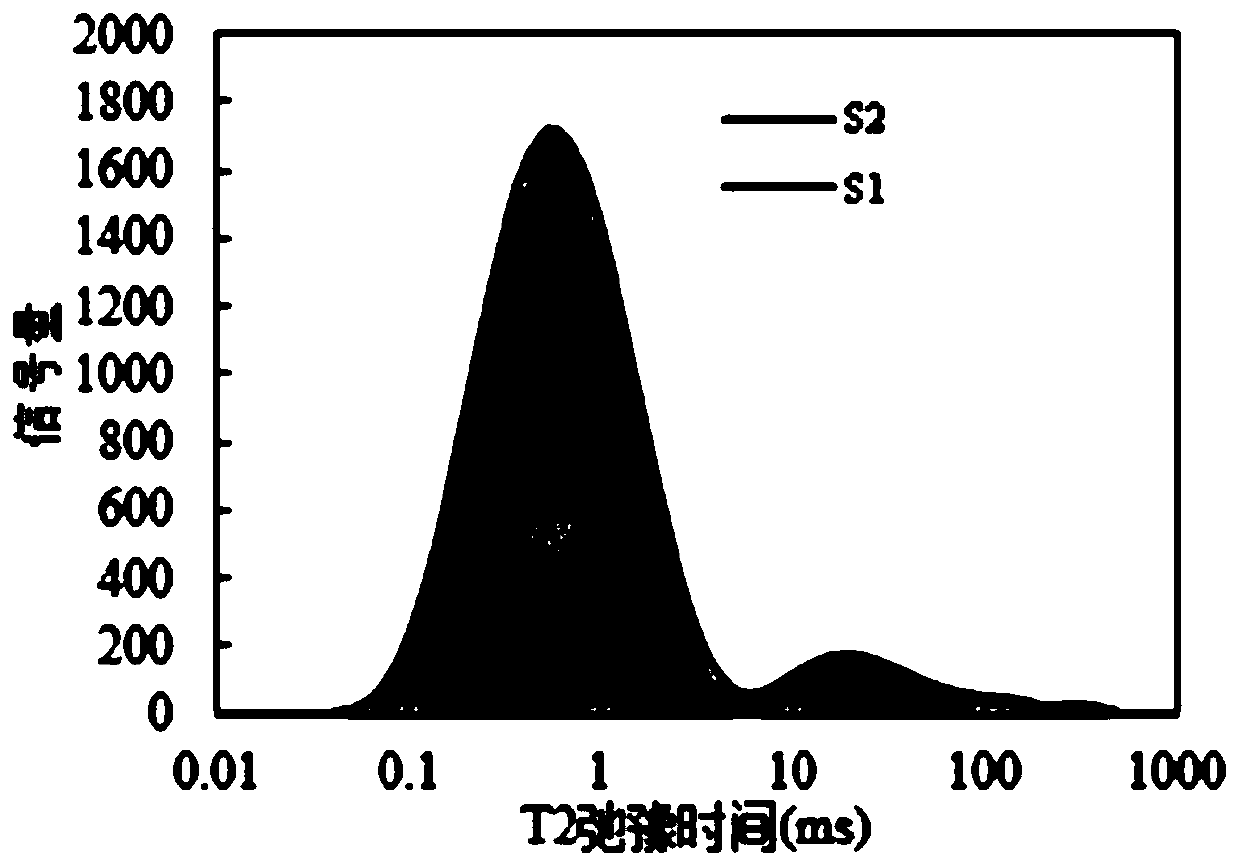

ActiveCN109443867BPoor accuracyHigh precisionPreparing sample for investigationPermeability/surface area analysisFiberSpectral curve

The invention discloses a method for continuously detecting physical parameters of compact rocks. The method includes the steps: selecting a rock sample, drying the rock sample, measuring the size andweight of the rock sample, taking formation water, soaking a fiber with a gap, repeatedly rolling a rock core on the fiber, uniformly soaking the outer surface of the rock core except for two end surfaces, placing the rock sample into an adjusted nuclear magnetic resonance spectrometer to obtain a T2 spectral curve of the sample, taking out the rock sample to dry the rock sample, performing saturation treatment on the rock core by the formation water, and testing a T2 spectral curve by the nuclear magnetic resonance spectrometer; taking out the rock sample, placing the taken rock sample intoa rock core clamping device, applying displacement pressure until the displacement pressure reach a suitable displacement pressure difference value, accurately recording needed parameters after a system is stabilized, continuing to measure the rock sample by a soap film flow meter, measuring a T2 spectral curve of the rock sample again, and analyzing and calculating acquired data to obtain variousof needed parameters. The method has the advantages that data are accurate and reliable, time is saved, and the method is convenient and rapid.

Owner:SOUTHWEST PETROLEUM UNIV

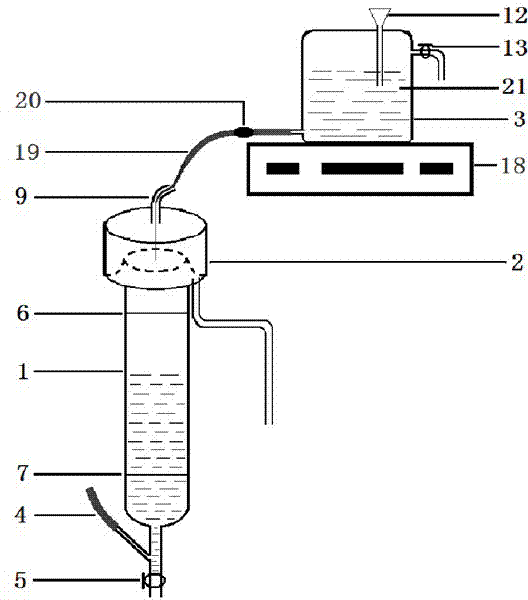

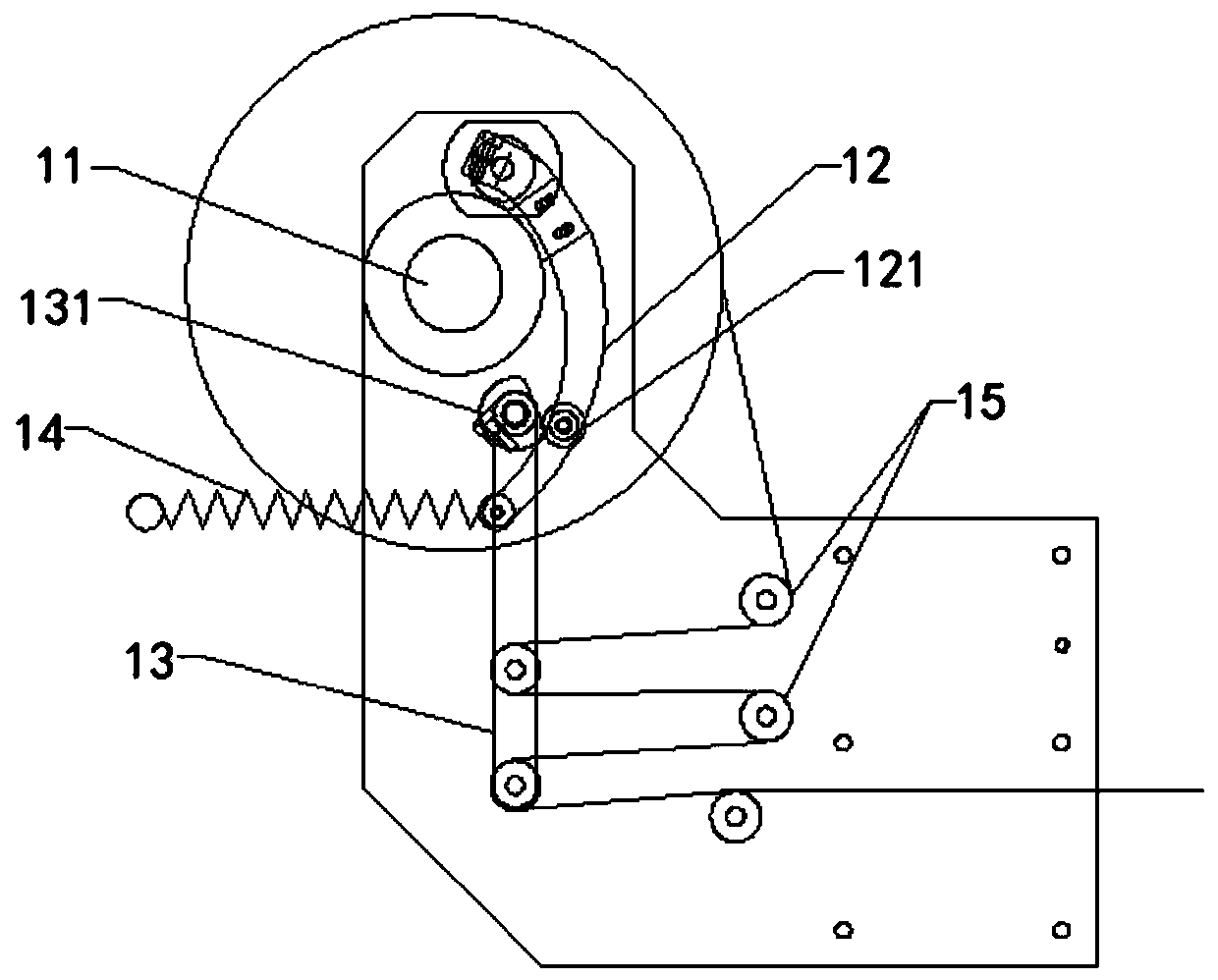

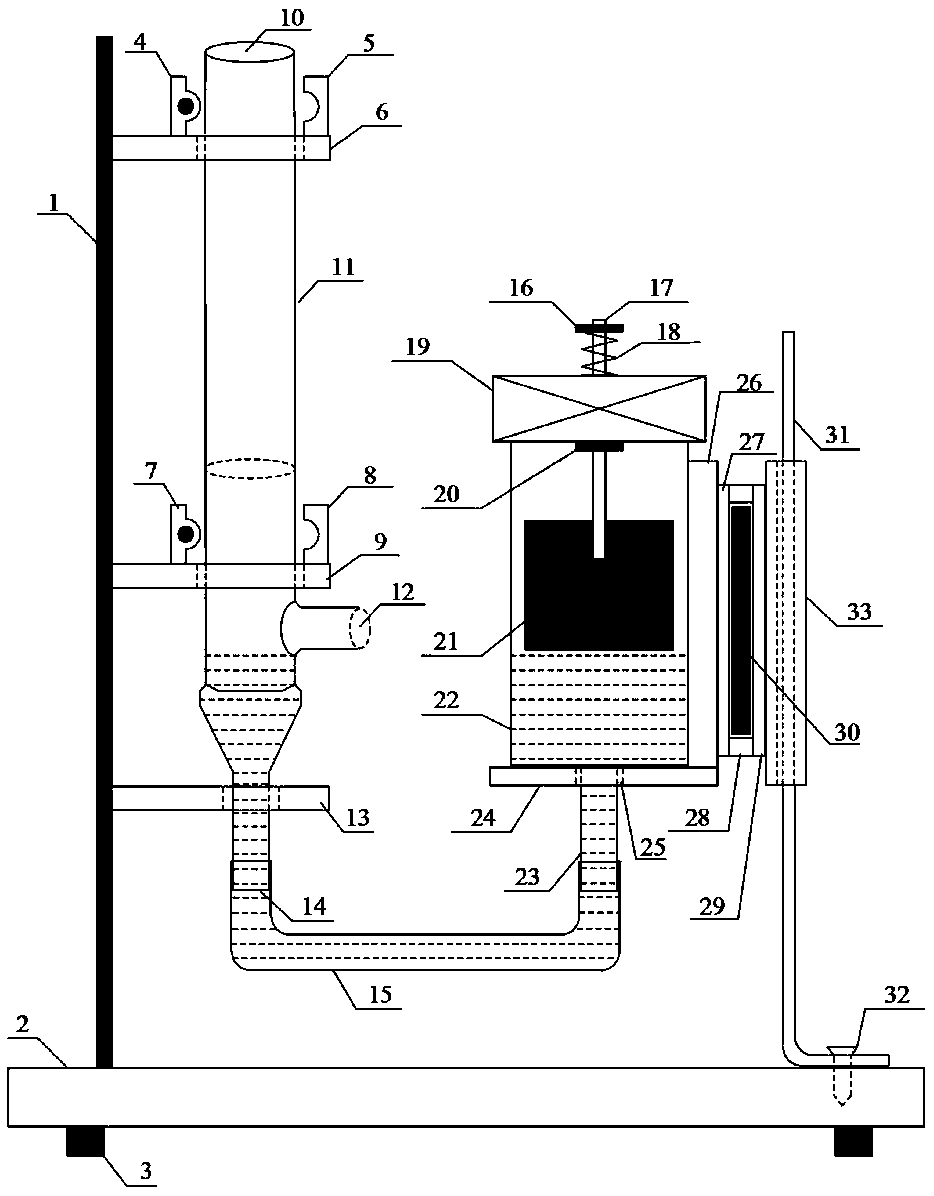

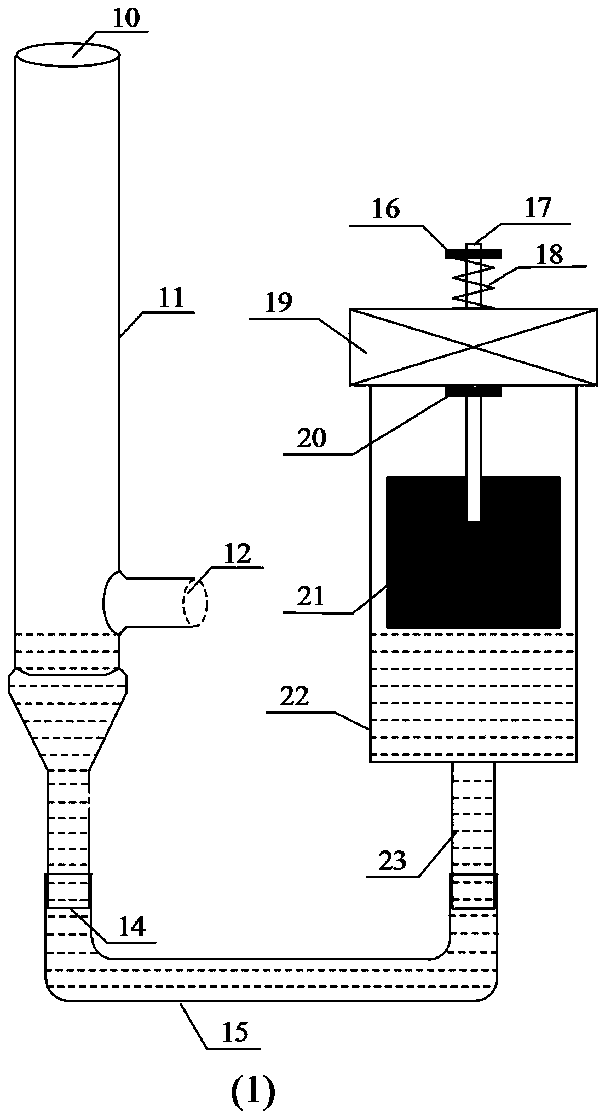

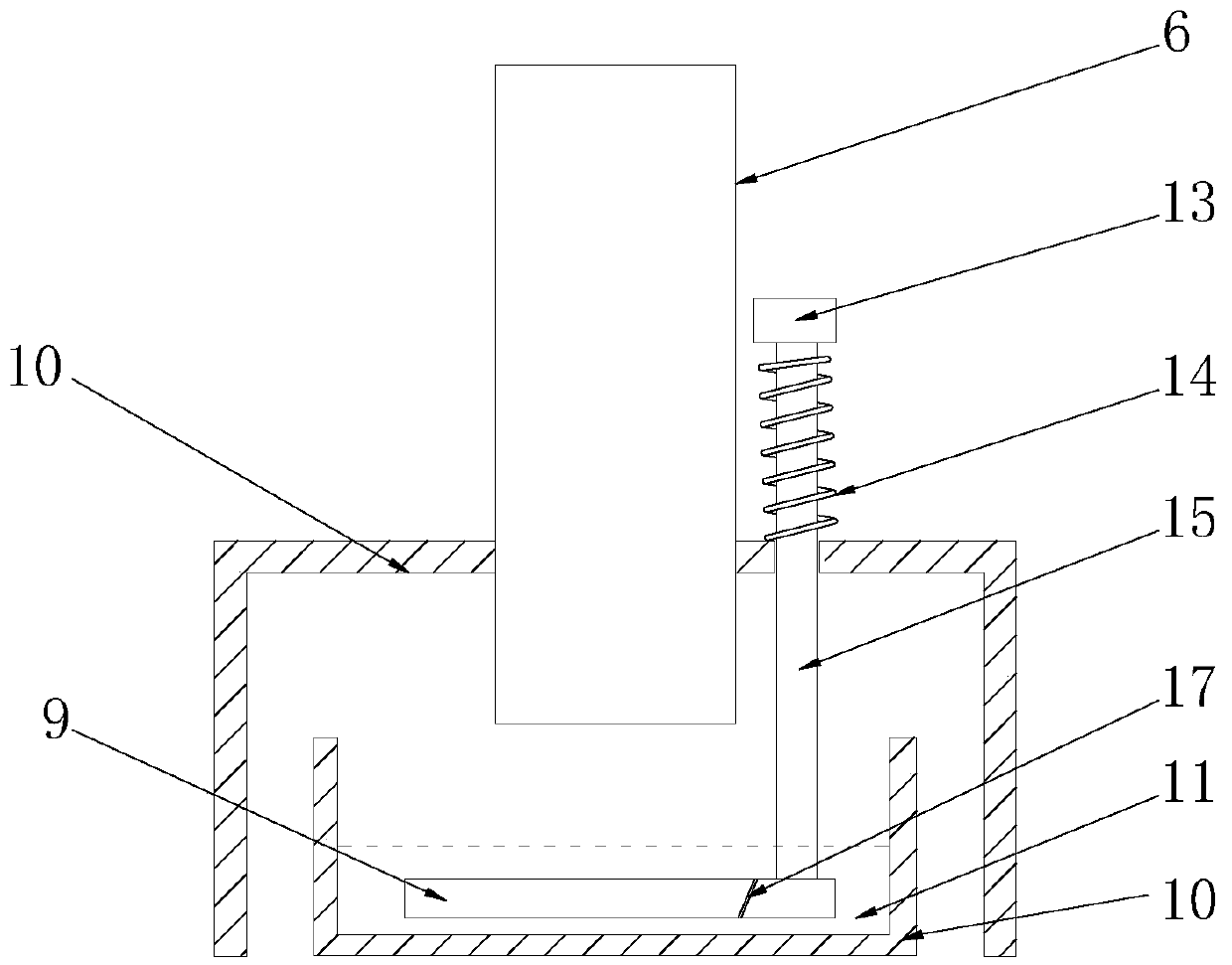

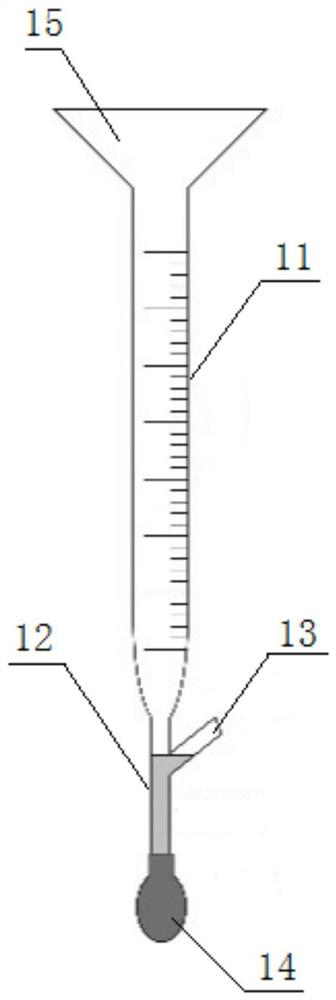

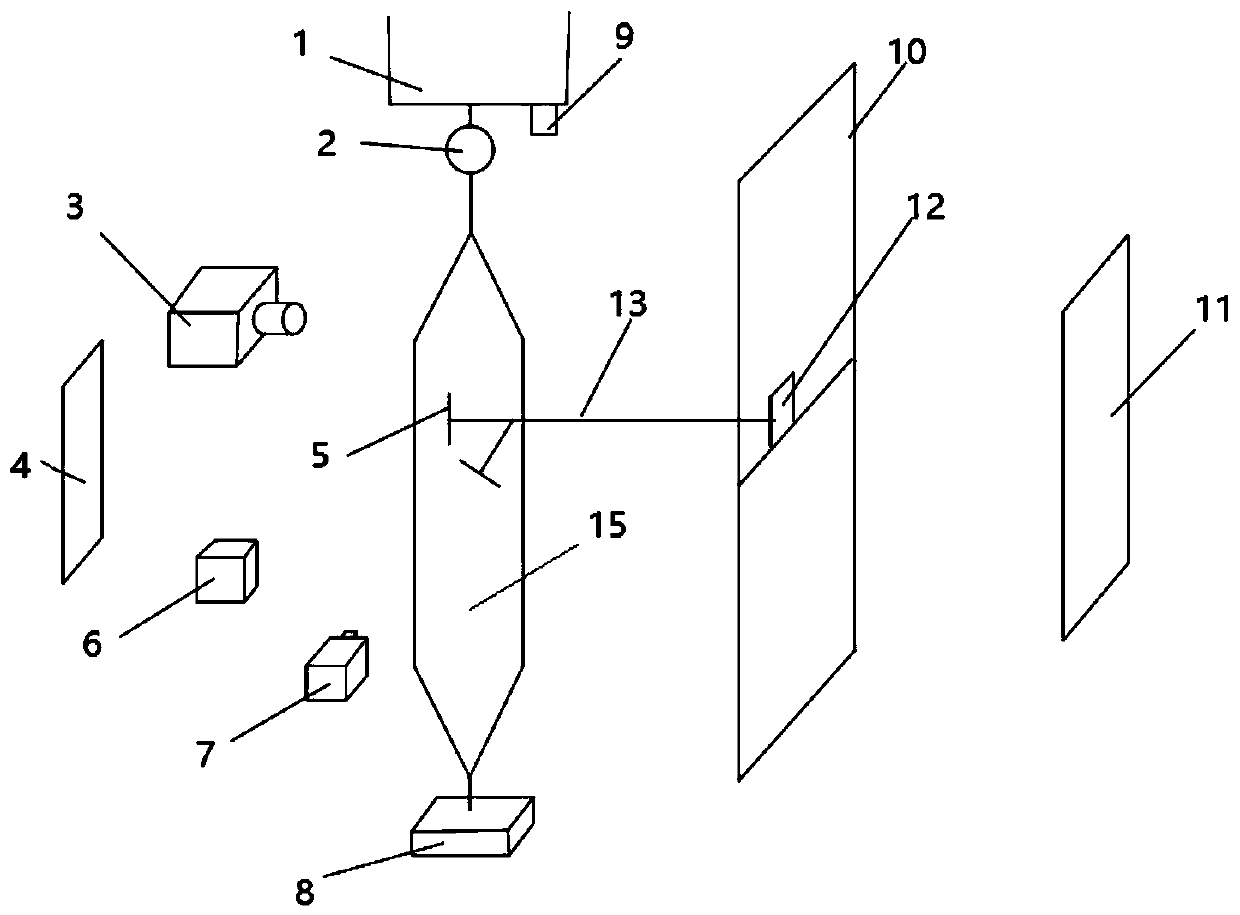

An electronic soap film flowmeter with automatic foam generation

ActiveCN106768125BFast solutionFull time contactContracting/expanding measuring chambersAutomatic controlSoap bubble

The invention provides an electronic soap film flowmeter automatically producing bubbles and belongs to the technical field of flow determination. The flowmeter consists of a soap tube, a soap tube supporting system, a photoelectric sensing system, a liquid level lifting system and a liquid level adjusting system. A magnetic force is produced by utilizing direct current through multi-turn coils and combines with the elastic force of a spring itself, a heavy hammer is driven to immerse into and float out of liquid by pushing and pulling a magnetic push-and-pull rod to ascend and descend, and the liquid level is lifted and reduced according to the Archimedes law to cause periodic rise and fall of the liquid level in the soap tube. Due to the damping effect of a communicating guide tube, the liquid level rising and falling speed is low, so that there is sufficient time for contact between a measured air source and soap liquid, thin soap bubbles are formed at first during liquid level falling, and the soap bubbles gradually become larger when the liquid level continues to fall and are finally separated from the liquid level to form a soap film. The process can be automatically controlled through an upper computer or a single chip microcomputer.

Owner:UNIV OF SCI & TECH BEIJING

Soap film flowmeter

PendingCN111289043AAvoid it happening againIdealized measurement situationVolume meteringVolume/mass flow by mechanical effectsEngineeringSoap film

The invention belongs to the technical field of measuring the flow of fluid continuously passing through an instrument and discloses a soap film flowmeter. The soap film flowmeter comprises a soap film tube, an upper infrared transmitting tube and an upper infrared receiving tube which are arranged at the upper part of the outer wall of the soap film tube, a lower infrared transmitting tube and alower infrared receiving tube which are arranged at the lower part of the outer wall of the soap film tube, and a soap liquid pool and a film lifting ring which are arranged below the soap film tube.The film lifting ring is provided with a film breaking structure. According to the technical scheme, the annular film formed by the outer wall of the soap film tube and the inner wall of the film lifting ring is torn or vibrated to be broken through the cracks of the film lifting ring under the action of a film breaking column and a spring, so that the film is successfully broken, double films areprevented from being generated, the measurement condition is idealized, and the detection data is accurate.

Owner:青岛巉山环保科技有限公司

Hot-press coated steel sheet, method of manufacturing hot-press coated steel sheet, method of manufacturing hot-press formed product, and method of manufacturing vehicle

The present invention relates to a plated steel sheet for hot pressing and a method for producing the same. The plated steel sheet for hot pressing has a plated steel plate body and a zinc-based metal soap film. Aluminum coatings on both sides, the zinc-based metal soap film is provided on the aluminum coating side of the plated steel sheet body, and the adhesion amount is 7.1 to 19.8 g / m in conversion of Zn amount 2 , wherein, in the plated steel sheet body, in the case of having a zinc oxide film on the surface of the aluminum plating layer, the total adhesion amount of the above-mentioned zinc oxide film and the above-mentioned zinc-based metal soap film is 7.1 to 19.8 g in terms of Zn amount / m 2 . In addition, the present invention relates to a method of manufacturing a hot-press formed product using the plated steel sheet for hot pressing and a method of manufacturing a vehicle using the press-formed product manufactured by the method of manufacturing the hot-press formed product.

Owner:NIPPON STEEL CORP

An equal-thickness interference demonstration device and demonstration method

The invention relates to a device and method for equal thickness interference presentation. The device includes a container with the top end provided with a circular opening. When the circular openingis sealed with a soap film, the pressure in the container can be adjusted, and when the pressure in the container is changed, the shape of the soap film can be changed. The device and method for equal thickness interference presentation can show an interference pattern of a Newton ring, and can also show a wedged interference pattern. In addition, the device can not only display an equal thickness interference pattern with the thin center and the thick periphery, but also can display an equal thickness interference pattern with the thick center and the thin edge.

Owner:HENAN UNIV OF SCI & TECH

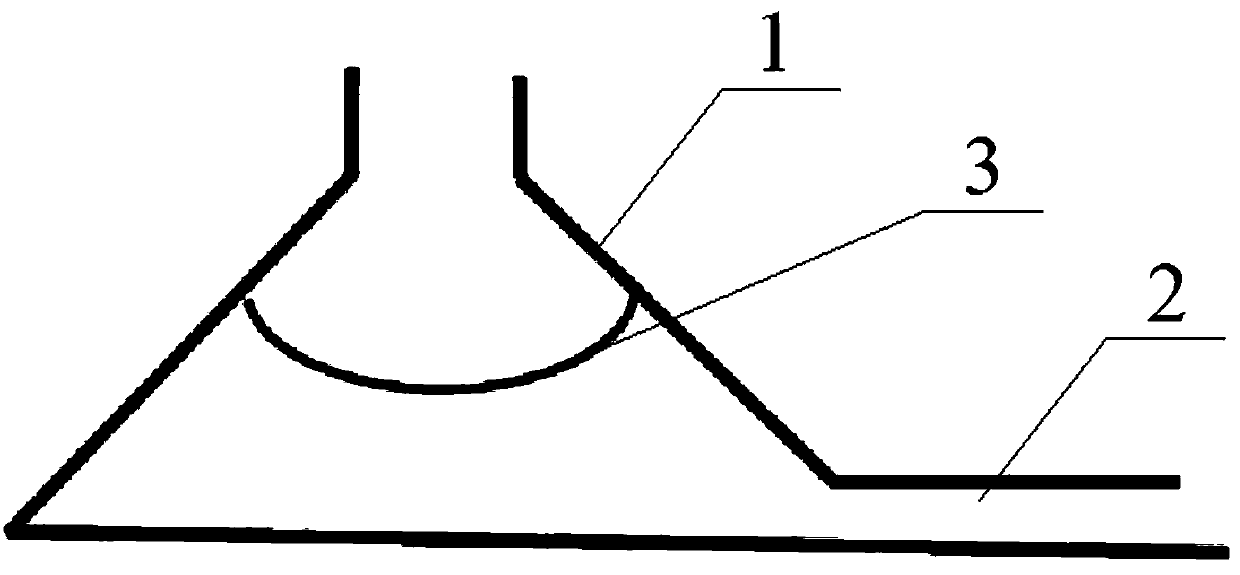

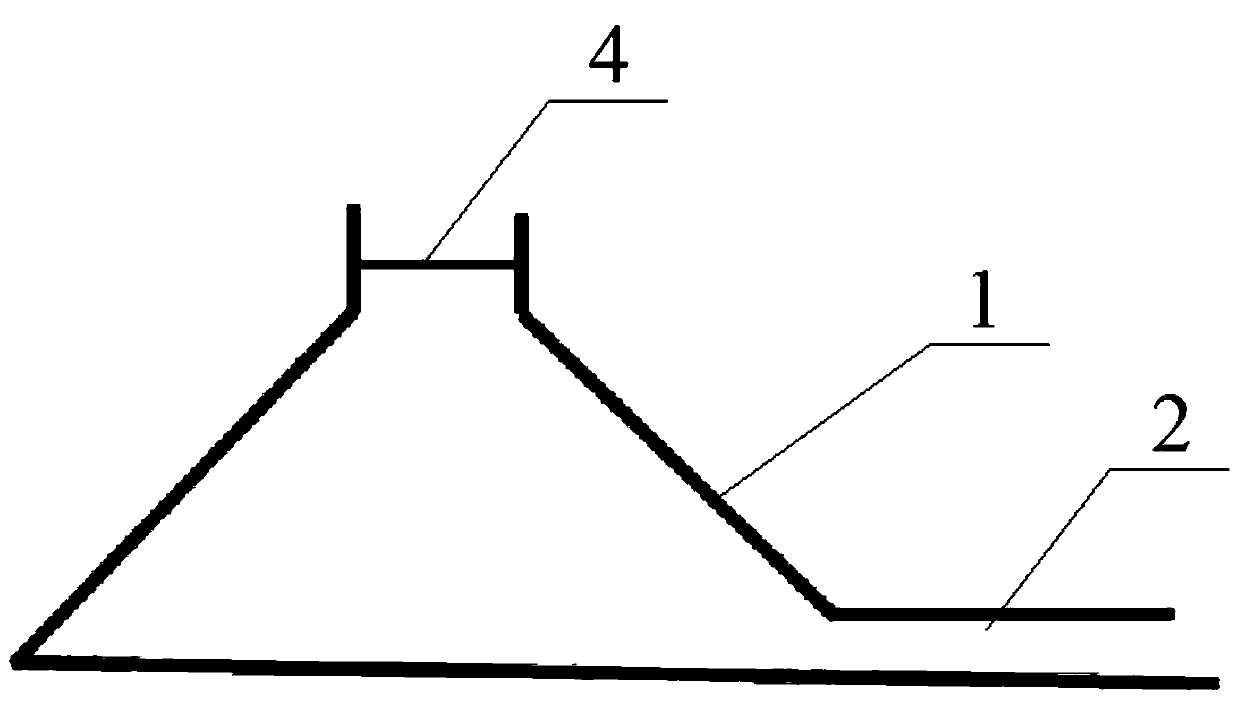

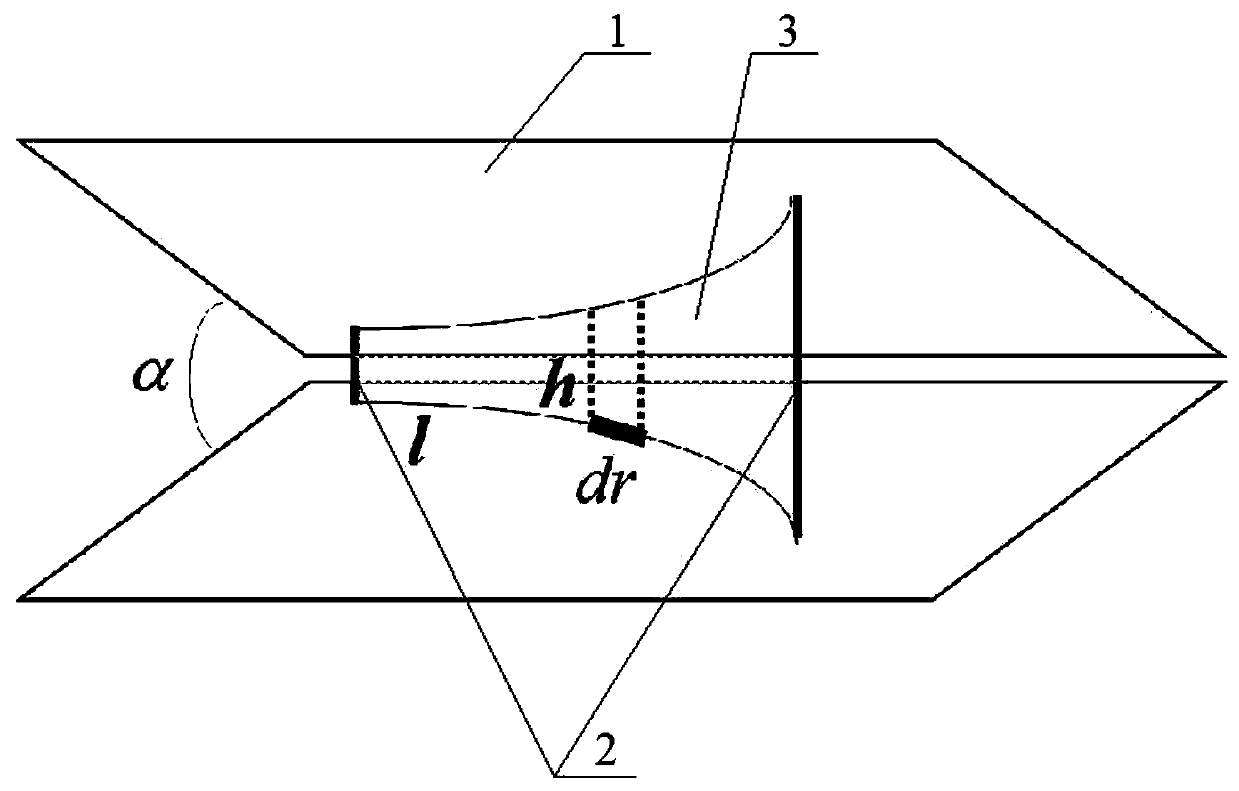

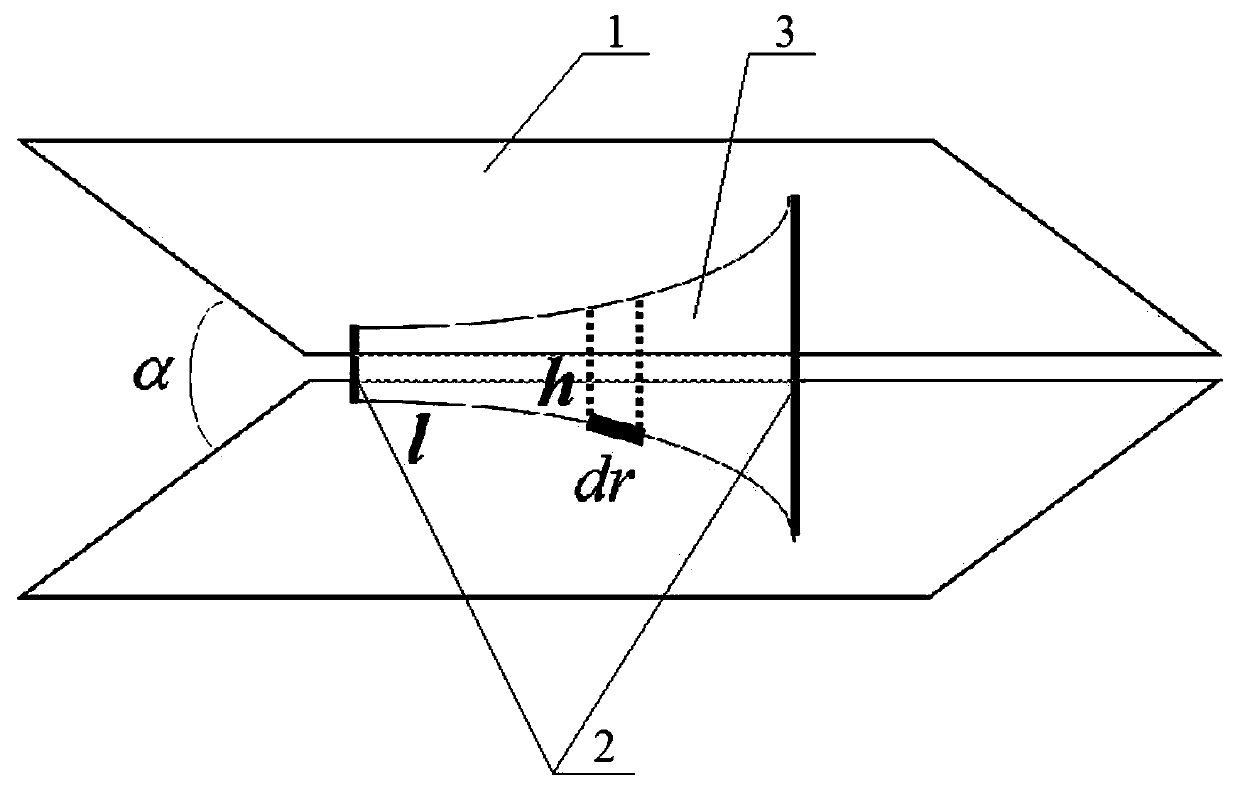

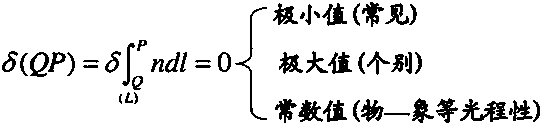

Demonstration device for propagation path of light in medium with constant serving as refractive gradient

InactiveCN107689185AThe transmission path is intuitiveSimple structureEducational modelsRefractive indexSoap film

The invention relates to a demonstration device for a propagation path of light in a medium with a constant serving as a refractive gradient. The device comprises two glossy flat plates, the includedangle between the two glossy flat plates is smaller than 90 degrees, the bottom glossy flat plate is horizontal, the two glossy flat plates are fixedly connected through two connecting columns, and the two connecting columns are perpendicular to the horizontal glossy flat plate. The device is soaked into soapy water and then taken out, a soap film is formed between the two connecting columns, andthe intersecting line of the soap film and the bottom horizontal glossy flat plate is the propagation path of the light in the medium with the constant serving as the refractive gradient. The device can visually demonstrate the propagation path of the light in the medium with the constant serving as the refractive gradient, and is simple in structure, convenient and practical.

Owner:HENAN UNIV OF SCI & TECH

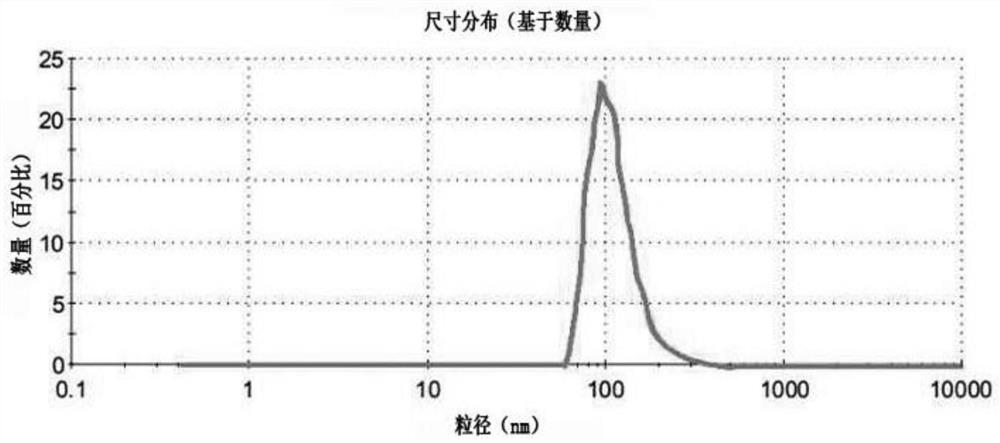

Batch-type preparation device and preparation method of nano-hydrogen bubble/diesel mixed fuel

InactiveCN110240952BHigh thermal efficiencyImprove economyLiquid carbonaceous fuelsDieselingPollutant emissions

The invention discloses an intermittent preparation method of nanometer hydrogen bubble / diesel mixed fuel. After diesel is added into a mixer, sealing is performed; after pressure reduction and pressure regulation, hydrogen gas is supplied to the mixer at the constant pressure of 0.5 to 5MPa; the temperature of diesel in the mixer is regulated to the constant temperature being room temperature to 150 DEG C; after the stirring is performed for 30 to 120min, air supply stops; a micro-regulation valve is opened; the gas flow speed in the soap film flowmeter is regulated to be 0.1 to 1ml / min; diesel and hydrogen overflowing flow the mixer are released; after the pressure reaches ordinary pressure, a sealing plug is taken down; an oil drain valve is opened; the released fluid is the nanometer hydrogen bubble / diesel mixed fuel. When the mixed fuel is applied, a diesel engine only needs a set of oil supply system; the regulation on oil supply system hardware is not needed; the fuel oil economical efficiency of the diesel engine is greatly improved; the pollutant discharging is reduced. The combustion performance of mixed fuel on the diesel engine is improved; the long-period stable existence of hydrogen bubbles is facilitated; the uniformity and the stability of the nanometer hydrogen bubble / diesel mixed fuel are ensured.

Owner:TIANJIN UNIV

A demonstration device of the propagation path of light in a medium with a constant gradient of refraction

InactiveCN107689185BThe transmission path is intuitiveSimple structureEducational modelsRefractive indexSoap film

The invention relates to a demonstration device for a propagation path of light in a medium with a constant serving as a refractive gradient. The device comprises two glossy flat plates, the includedangle between the two glossy flat plates is smaller than 90 degrees, the bottom glossy flat plate is horizontal, the two glossy flat plates are fixedly connected through two connecting columns, and the two connecting columns are perpendicular to the horizontal glossy flat plate. The device is soaked into soapy water and then taken out, a soap film is formed between the two connecting columns, andthe intersecting line of the soap film and the bottom horizontal glossy flat plate is the propagation path of the light in the medium with the constant serving as the refractive gradient. The device can visually demonstrate the propagation path of the light in the medium with the constant serving as the refractive gradient, and is simple in structure, convenient and practical.

Owner:HENAN UNIV OF SCI & TECH

Soap film water hole test device

The invention provides a soap film water hole test device, which can realize effective control of soap film flow and can adjust test related parameters according to test requirements. The soap film water hole test device includes: an external frame, an internal frame and a position locking mechanism; the left and right ends of the internal frame are supported on the external frame by bearings, and can rotate around the axis of the bearing to change the rotation angle of the internal frame; the position locking mechanism is used After the internal frame is rotated to the set angle, the position of the internal frame is locked; the internal frame includes: brackets, bracket guide rails, wires, upper water tank, lower water tank and mold table; the mold table is used to fix the mold required for the test; the test is adopted The device can adjust the length and position of the test area, change the width of the test area (that is, the width of the soap film), and change the test angle according to the test needs; thus construct two-dimensional water tunnels with different parameters to adapt to different models; and can change the flow field velocity.

Owner:北京启航凯博科技有限公司

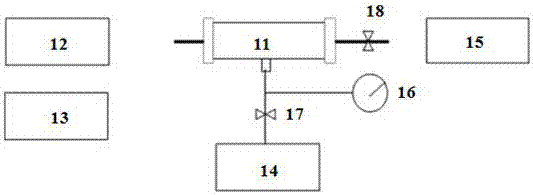

Channel type vacuum standard leak hole detection device and method

PendingCN112665805AEasy to testImprove universalityMeasurement of fluid loss/gain rateTesting/calibration apparatusCapacitanceThin membrane

The invention relates to a channel type vacuum standard leak hole detection device which comprises an air source, a pressure stabilizing cavity, a molecular pump, a mechanical pump and an air storage tank. The vacuum end of the detected channel type vacuum standard leak hole is connected with the pressure stabilizing cavity, and the atmospheric end is simultaneously communicated with a gas flow meter group, a first soap film flow meter and a second soap film flow meter; the lowest detection flow in the flow meter group is greater than that of the first soap film flow meter, and the detection flow of the first soap film flow meter is greater than that of the second soap film flow meter; the voltage stabilizing cavity is respectively communicated with a group of capacitive film vacuum gauges with pressure values from low to high in a cut-off manner; the pressure stabilizing cavity is respectively communicated with the molecular pump and the mechanical pump in a cut-off manner; the pressure stabilizing cavity is communicated with the gas in a cut-off manner; the molecular pump is communicated with the gas storage tank; and the molecular pump, the gas storage tank and the mechanical pump are communicated in a disconnectable manner. The device can adapt to leakage rate detection of leak holes in all set pressure ranges, and is convenient to test, high in universality and high in measurement precision.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

An automatic film-opening soap film flowmeter

ActiveCN103925957BReduce test errorImprove test efficiencyTesting/calibration apparatusVolume/mass flow measurementCommunicating vesselsEngineering

The invention provides an automatic film-opening type soap film flowmeter, comprising a soap film pipe, a soap film production device and a soap film recovery device; the soap film production device comprises a soap liquid pipe and an air intake pipe, and the air intake pipe is arranged on the upper part of the soap liquid pipe The soap film recovery device includes a soap film recovery cover, a soap recovery tube and a soap recovery cup, one end of the soap recovery tube is connected to the soap recovery cover on the top of the soap film tube, and the other end extends into the soap recovery cup; Soap liquid is housed in the recovery cup, and the bottom of the soap liquid pipe is connected to the bottom side wall of the soap film recovery cup, and the liquid level of the soap liquid is at the same height as the top of the air inlet of the air intake pipe. The invention adopts the principle of the connecting device to realize the mode of automatic film opening, which makes up for the defect of manual film opening and reduces the verification error.

Owner:XINJIANG UYGUR AUTONOMOUS REGION INST OF MEASUREMENT & TESTING

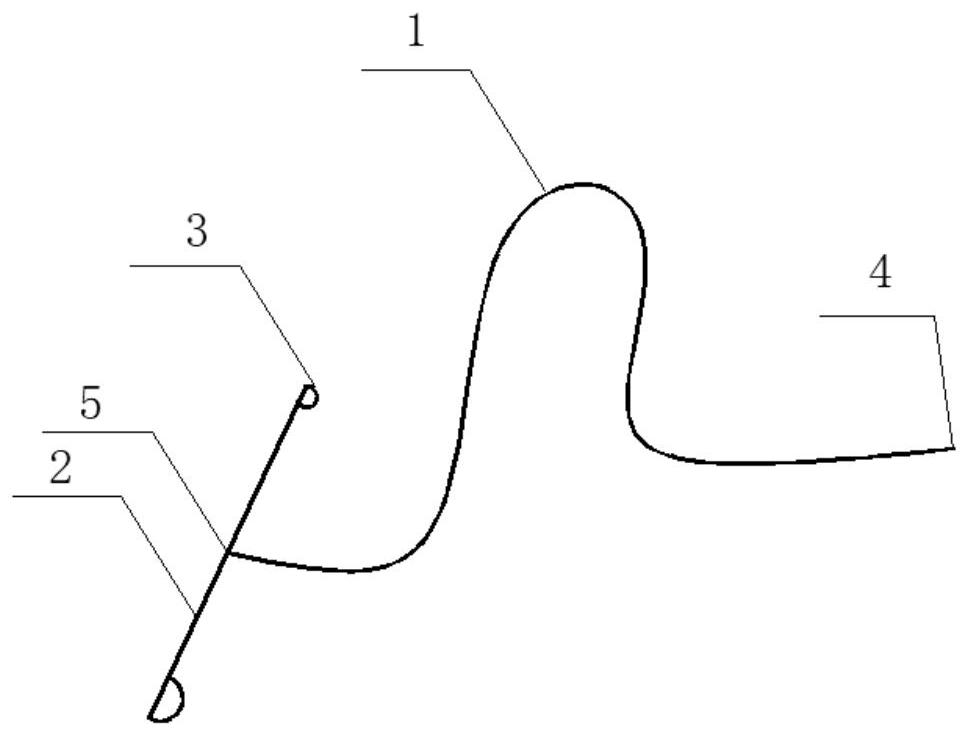

A curved-neck model support device for soap film water tunnel experiments

The invention discloses a curved neck type model support device for soap film water tunnel experiments, relates to the field of fluid mechanics, and comprises a curved neck with a height difference at both ends and a beam with closed loops at both ends; the curved neck consists of A thin wire is bent, and there is a height difference between the front and rear ends of the curved neck, the rear end of the curved neck is higher than the front end of the curved neck, and the front end of the curved neck is inclined downward; The curved neck can conveniently adjust the position of the six degrees of freedom of the model; the filaments are fixed by the closed loops at both ends of the beam. The invention can conveniently replace the experimental model in the soap film water hole experiment, prevent the backflow of the soap liquid, and can adjust the six degrees of freedom. The material used is thin steel wire, which is easy to obtain and low in cost. The thin steel wire is easy to bend, But the rigidity is strong, which is convenient for the manufacture and use of the device.

Owner:SHANGHAI JIAOTONG UNIV

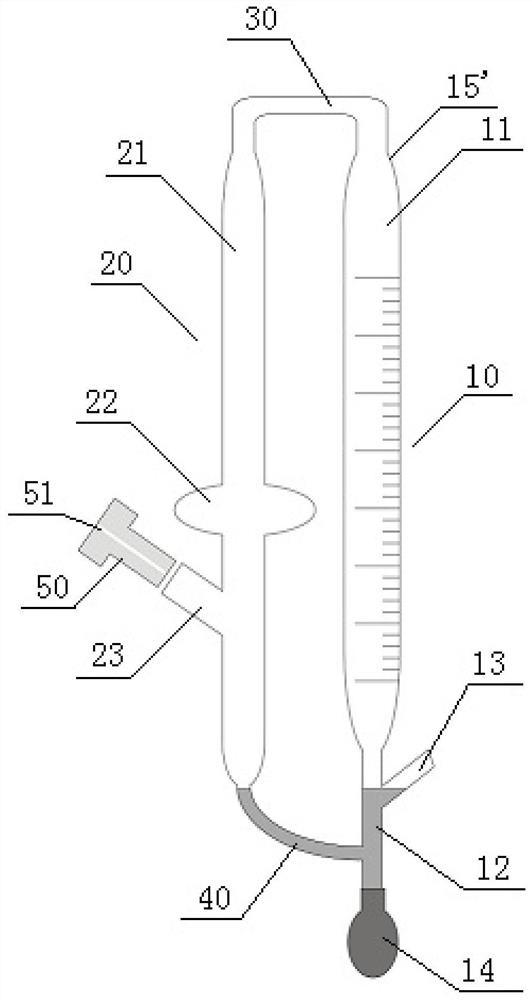

Soap film flowmeter for measuring large flow

PendingCN111289042AEvenly distributedAccurate measurementVolume meteringVolume/mass flow by mechanical effectsSoap filmMechanical engineering

The invention belongs to the technical field of measuring the flow of fluid continuously passing through an instrument, and discloses a soap film flowmeter for measuring a large flow. The soap film flowmeter comprises an upper cavity, at least two soap film tubes, a soap liquid pool, a film lifting ring and a film lifting ring lifting device, wherein the upper cavity is connected with the upper portion of the outer wall of each soap film tube in a sealed mode, the film lifting ring is connected with the film lifting ring lifting device, and infrared geminate transistors are arranged on the upper portion and the lower portion of the outer wall of each soap film tube respectively. According to the technical scheme, a plurality of soap film tubes are arranged, so that the capacity of large flow for each soap film tube is dispersed, and the precision of large flow measurement is the same as the measurement precision of each soap film tube; a soap film formed by the outer wall of the soap film tube and the inner wall of the film lifting ring is torn or vibrated to be broken through the crack of the film lifting ring under the action of a film breaking column, so that the film is successfully broken, double films are avoided, meanwhile, high-flow accurate measurement and double-film avoidance are achieved, the measurement condition is idealized, and the detection data is accurate.

Owner:青岛巉山环保科技有限公司

Soap film flowmeter

PendingCN114427894AEliminate the effects ofWon't breakVolume meteringVolume/mass flow by differential pressureStraight tubeControl theory

The invention provides a soap film flowmeter, which comprises a metering tube used for testing the volume or the flow rate of gas; the parallel straight pipe is parallel to the metering pipe and is provided with an exhaust port, the parallel straight pipe is communicated with the metering pipe at the top end through an upper bridge pipe, and the parallel straight pipe is communicated with the metering pipe at the bottom end through a lower bridge pipe; wherein the diameter of the upper bridge pipe is smaller than that of the metering pipe. By means of the soap film flowmeter, bubbles can be brought into the parallel straight pipes to be broken and recycled, and measurement of the next period in the metering pipe is not affected.

Owner:CHINA PETROLEUM & CHEM CORP +1

Soap film flowmeter capable of automatically wetting soap tube and adjusting liquid level speed and testing method

PendingCN114877961AAvoid the phenomenon of conjunctivaVolume/mass flow measurementVolume meteringSoap filmMechanical engineering

The invention provides a soap film flowmeter capable of automatically wetting a soap tube and adjusting the liquid level speed and a testing method, and belongs to the technical field of soap film flowmeters. The flow meter comprises a soap film speed measuring module, a liquid soap buffering module, a liquid level sensing and measuring module and a gas circuit integrated control module, the soap film speed measuring module is installed on the left side of the upper portion of the liquid soap buffering module, the gas circuit integrated control module is installed on the right side of the upper portion of the liquid soap buffering module, and the liquid level sensing and measuring module is installed on one side of the bottom of the liquid soap buffering module. According to the soap film flowmeter, the purpose that the liquid level in a soap tube of the soap film speed measuring module rises and falls rapidly is achieved by controlling the pressure intensity of gas in the gas circuit integration module and through temporary storage buffering of the liquid soap buffering module. The soap film flowmeter can automatically complete the functions of soap tube wetting, liquid level monitoring, liquid level lifting speed control and the like.

Owner:UNIV OF SCI & TECH BEIJING

A conventional physical property tester device for reef cores based on microscopic samples

InactiveCN106324217BRealize full physical property measurementFlexible loading and unloading designEarth material testingPermeability/surface area analysisPorosityMeasurement device

The invention discloses a miniature sample-based biological reef rock conventional physical property tester device. The tester device comprises a miniature sample-based biological reef rock conventional physical property tester, a penetration rate testing device, a porosity measurement device, a booster pump, a soap film flowmeter, a pressure gauge and a switch, wherein the miniature sample-based biological reef rock conventional physical property tester comprises a cylinder body, a rubber sleeve, rubber sleeve end plugs, a cylinder body end cap, a cylinder body sealing cover and a sealing component; the cylinder body is of a hollow structure, the rubber sleeve and the rubber sleeve end plug are arranged in the cylinder body, and rock core samples are placed in the rubber sleeve; and the rubber sleeve end plugs are embedded into two ends of the rubber sleeve and are in direct contact with the rock core samples. According to the tester device, the different small-diameter rock cores can be clamped, and the normal operation of physical property testing can be guaranteed.

Owner:QINGDAO INST OF MARINE GEOLOGY +1

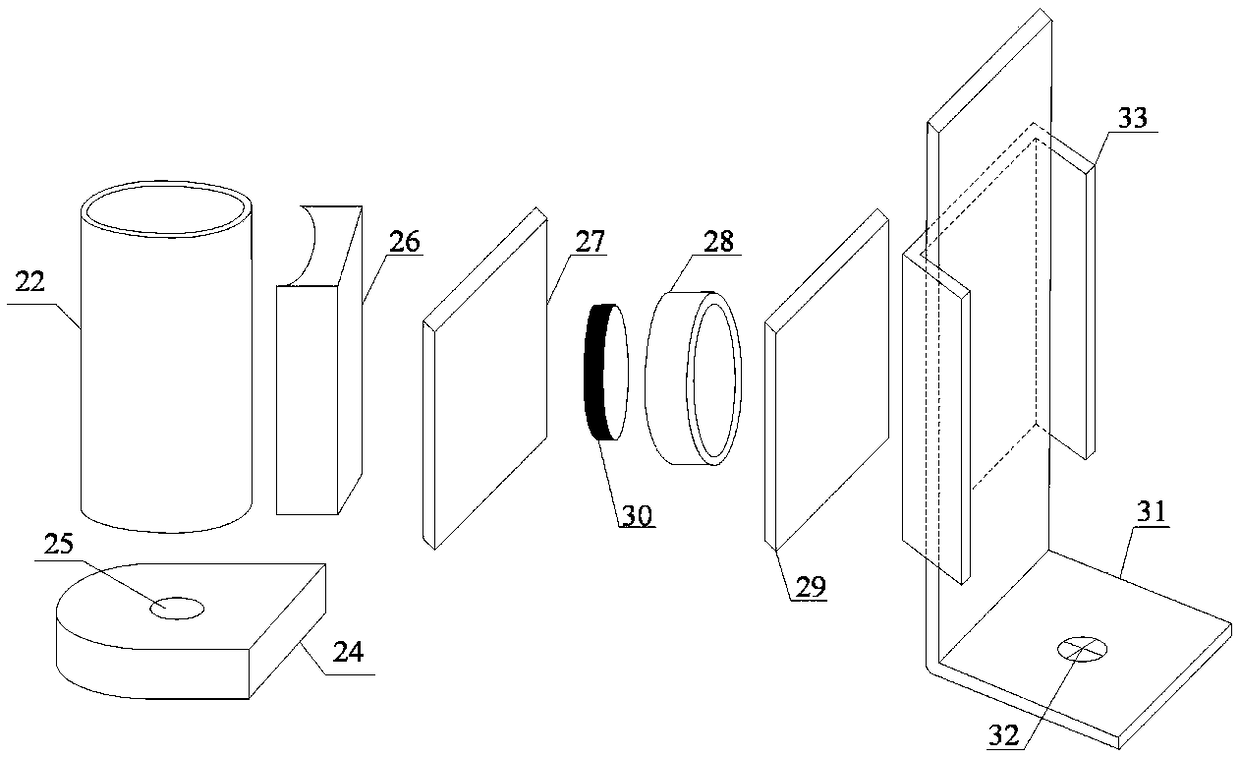

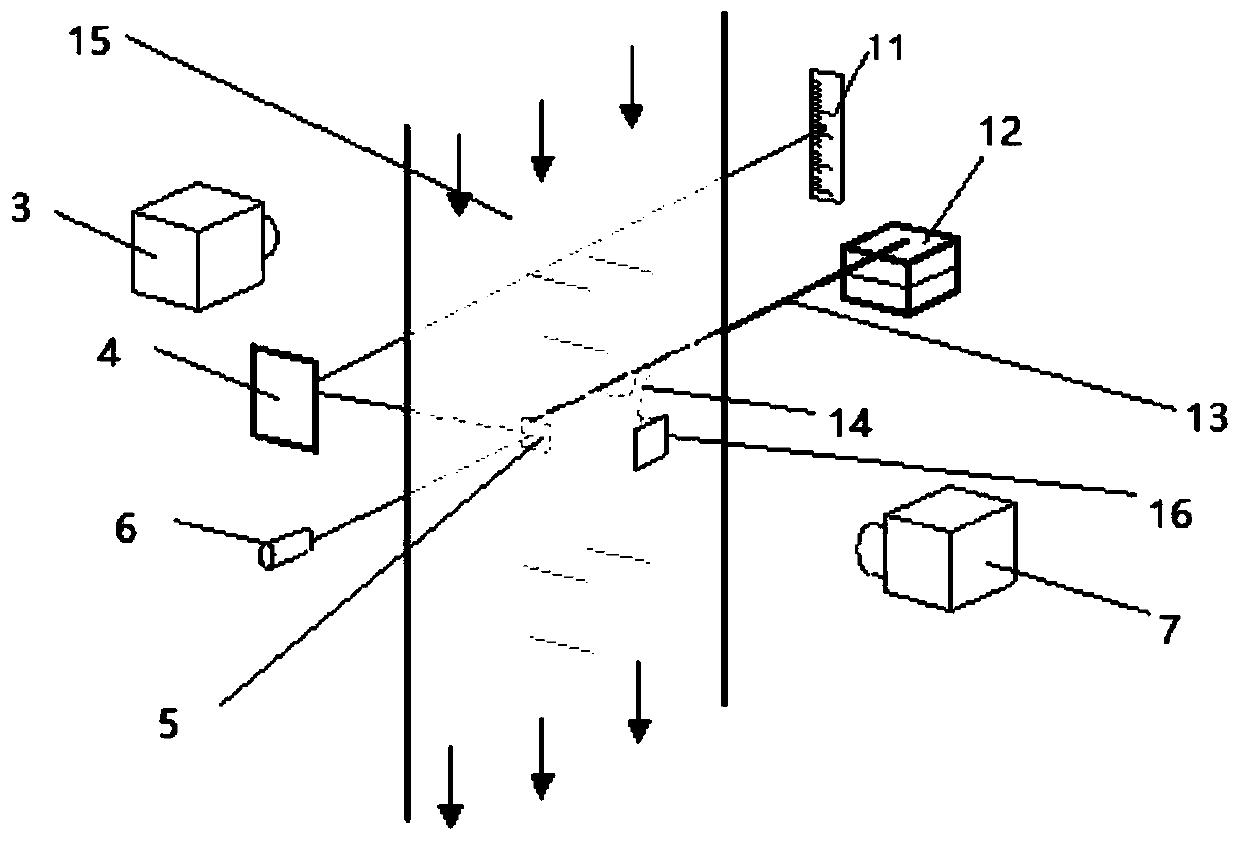

Single degree of freedom micro force measurement system for soap film water tunnel model experiment

PendingCN110542536AGood technical effectChange the layout of the spaceHydrodynamic testingCantilevered beamWater storage

The invention discloses a Single degree of freedom micro force measurement system for soap film water tunnel model experiment, related to the field of experiment equipment of experimental fluid mechanics. The system comprises an upper water storage device, a valved flowmeter, a recording camera, a second reflecting plane mirror, a first reflecting plane mirror, a laser emitter, a main camera, a lower water storage device, an upper water pump, a support frame, a receiving plane, a six-degree-of-freedom adjustor, a cantilever, a model support device, a soap film and an experimental model. The first reflecting plane mirror is parallel to the second reflecting plane mirror, the first reflecting plane mirror and the second reflecting plane mirror are perpendicular to the soap film; the main camera and the recording camera are arranged at two sides of the soap film; the cantilever is fixed on the six-degree-of-freedom adjustor; the six-degree-of-freedom adjustor is fixed on the frame of a soap film apparatus, and is located behind the soap film. According to the system provided by the invention, spatial arrangement of the force measurement system is changed, a real displacement value ofa laser point is obtained more accurately, and experiment precision is improved.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com