Electronic automatic verification device for soap film flow

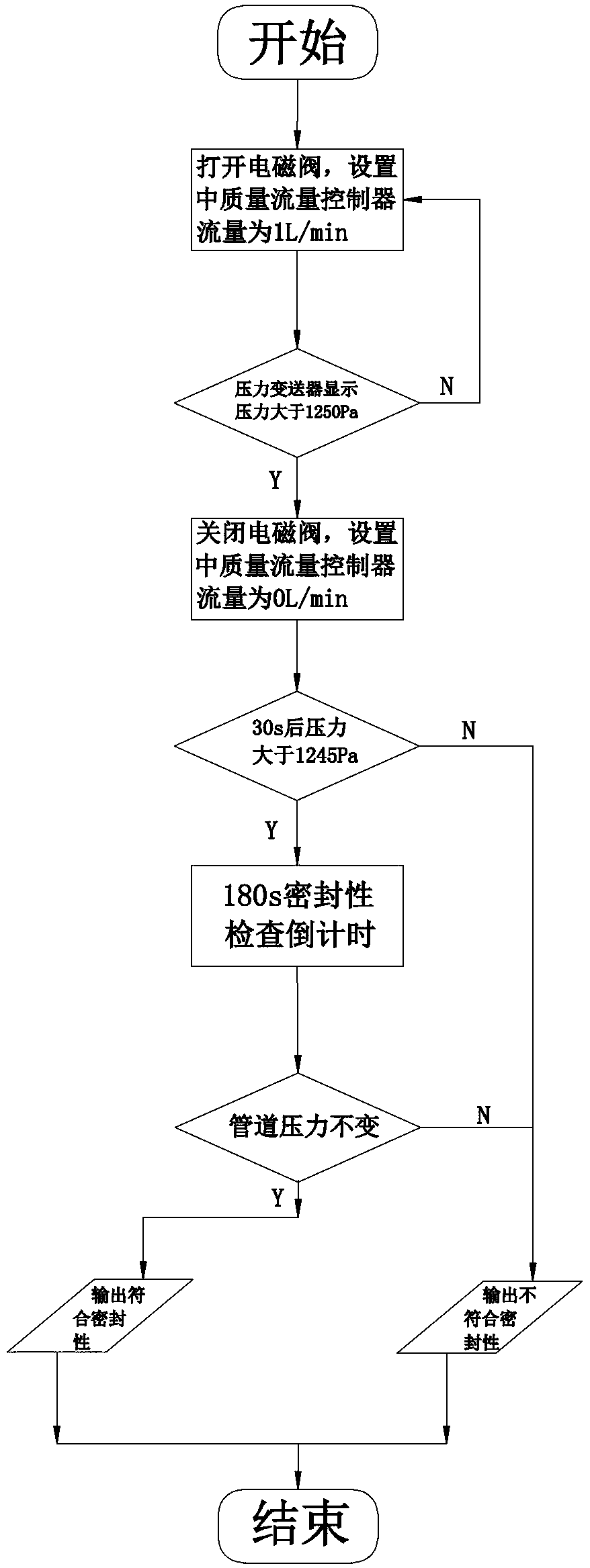

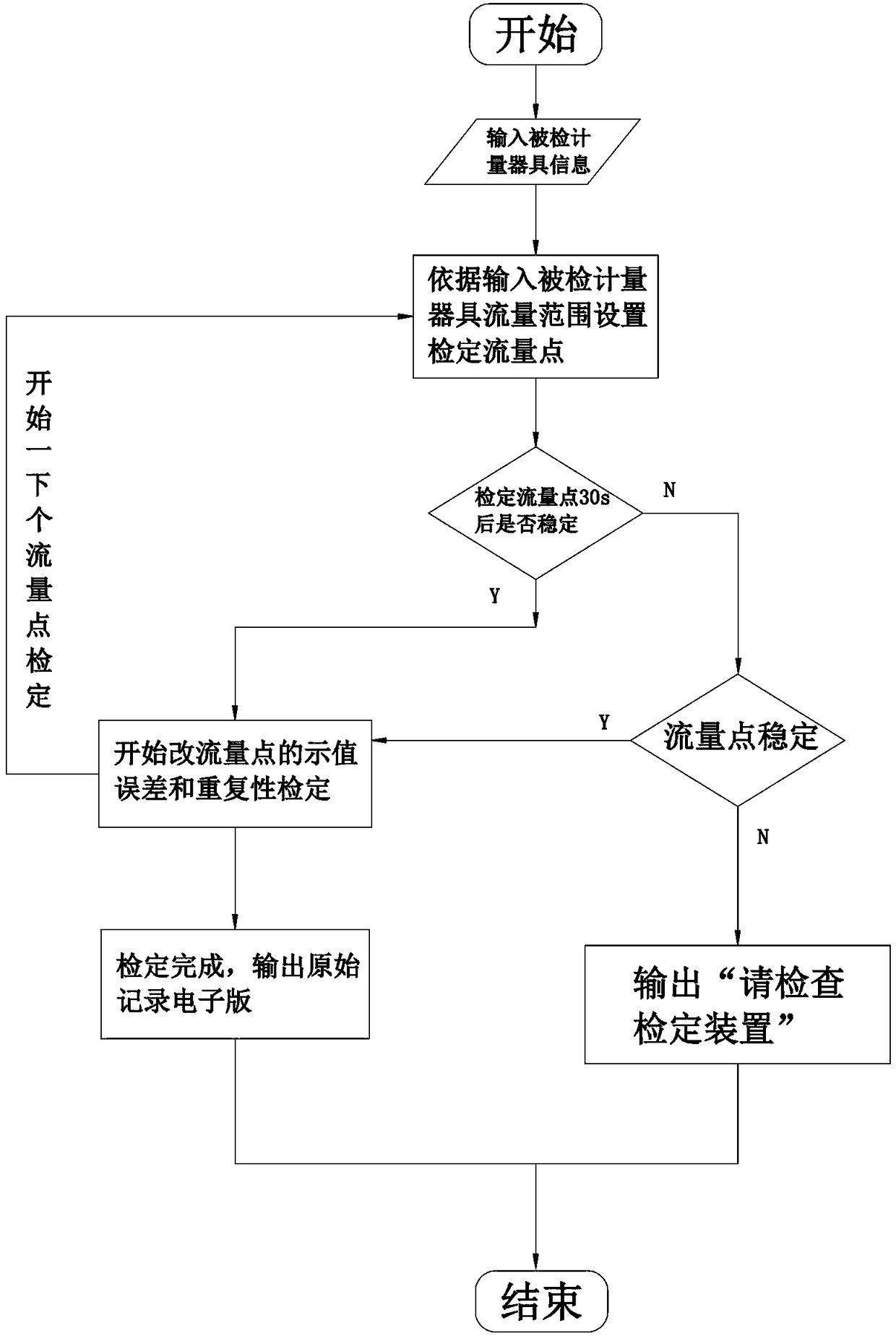

A verification device and soap film technology, applied in the direction of measurement device, test/calibration device, test/calibration volume flow, etc., can solve the problems of unstable output of the verification device, incomplete output flow range, and inability to automatically verify the flow point, etc. Achieve the effect of improving verification efficiency, low cost of use, and automation of sealing and verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

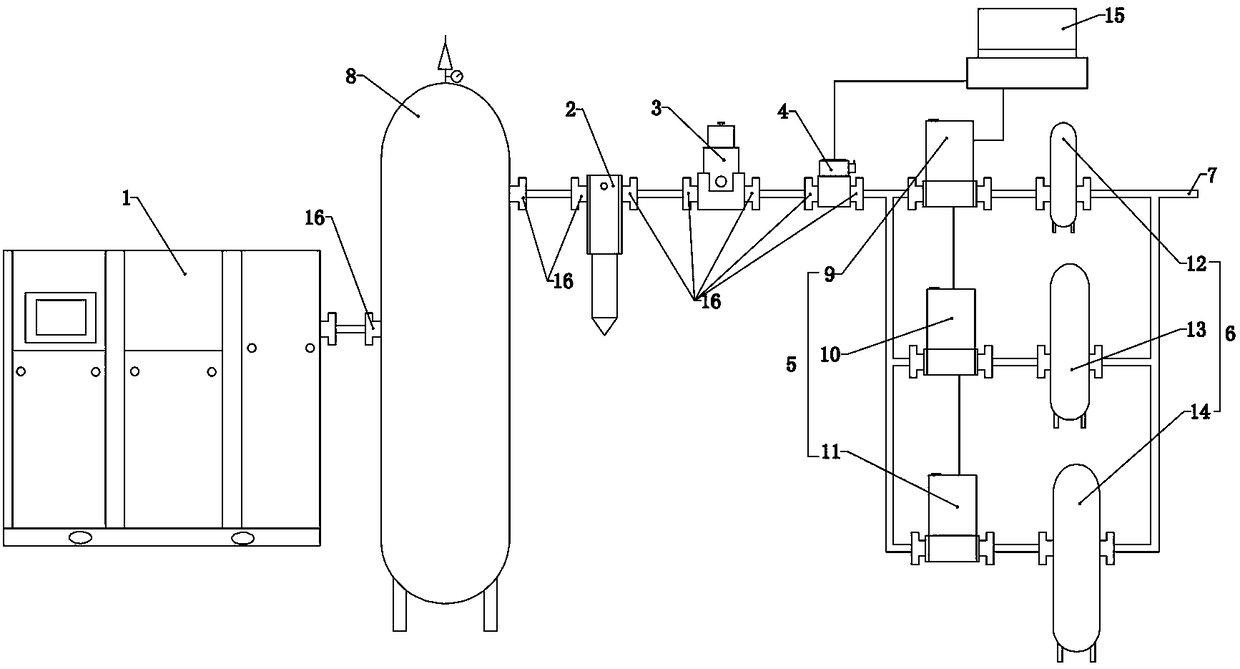

[0028] Embodiment 1, the present invention is an electronic soap film flow automatic verification device 1 system, which is characterized in that it includes an automatic pressure-stabilizing air source system, a pipeline system, a data acquisition and control system, and a host computer verification software system, wherein the automatic The stabilized air source system is used to provide a stable air source with a comprehensive output range for the device. The pipeline system is used for the verification of active flowmeters and passive flowmeters. The data acquisition and control system is used for Collect and automatically generate original records, and the verification software of the upper computer is used for the inspection and automatic verification of the airtightness of the device;

[0029] Including a gas source 1, the gas source 1 provides compressed gas for the system, one end of the gas source 1 is connected with a gas-liquid separator 2, and the gas-liquid separa...

Embodiment 2

[0030] Embodiment 2. On the basis of Embodiment 1, one end of the gas source 1 is connected to a gas storage tank 8, and the other end of the gas storage tank 8 is connected to a gas-liquid separator 2, that is, the gas storage tank 8 is located at Between the gas source 1 and the gas-liquid separator 2, the gas storage tank 8 is used to store the compressed gas output by the gas source 1, and the gas storage tank 8 is fixedly connected with a barometer so that the operator can read the gas storage tank 8, so that it can be adjusted in time.

Embodiment 3

[0031] Embodiment 3, on the basis of Embodiment 1, the air source 1 is provided by an air compressor, and the air source in this device is provided by an air compressor, which is relatively low in cost, and also conforms to the requirements of the follow-up structure in this device on the air source. basic requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com