Hot-press coated steel sheet, method of manufacturing hot-press coated steel sheet, method of manufacturing hot-press formed product, and method of manufacturing vehicle

A manufacturing method and steel plate technology, which is applied in the field of vehicle manufacturing, can solve problems such as surface deterioration, high heating temperature, and coating evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4、 comparative example 5~6

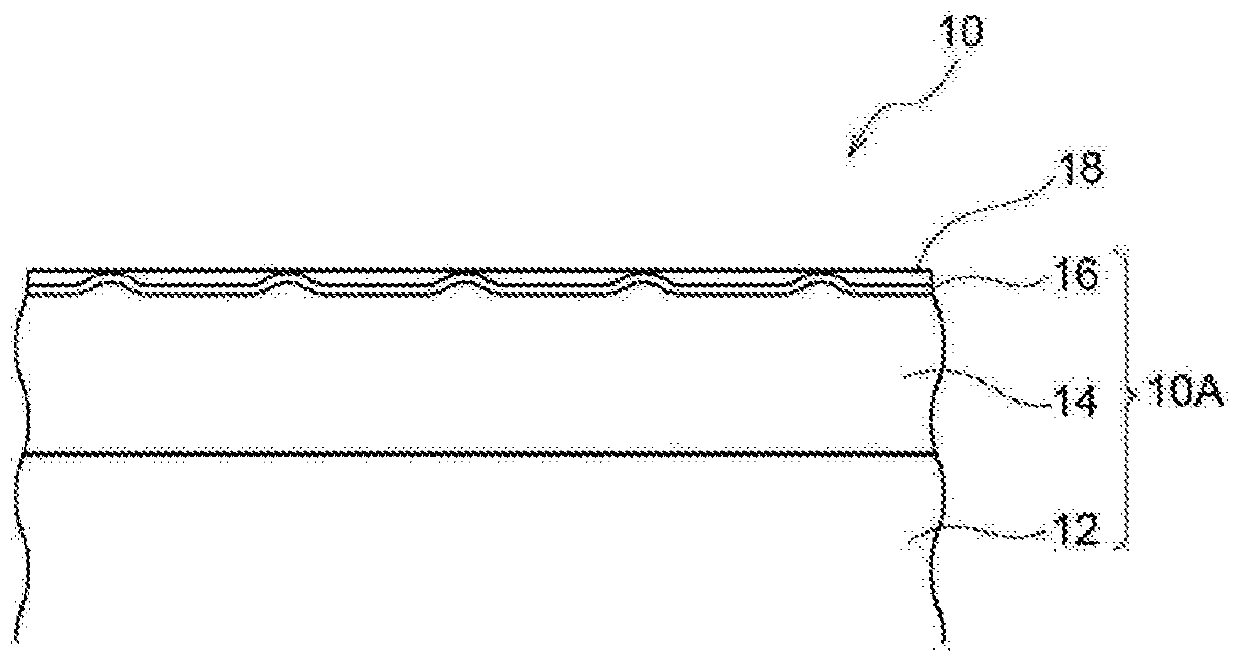

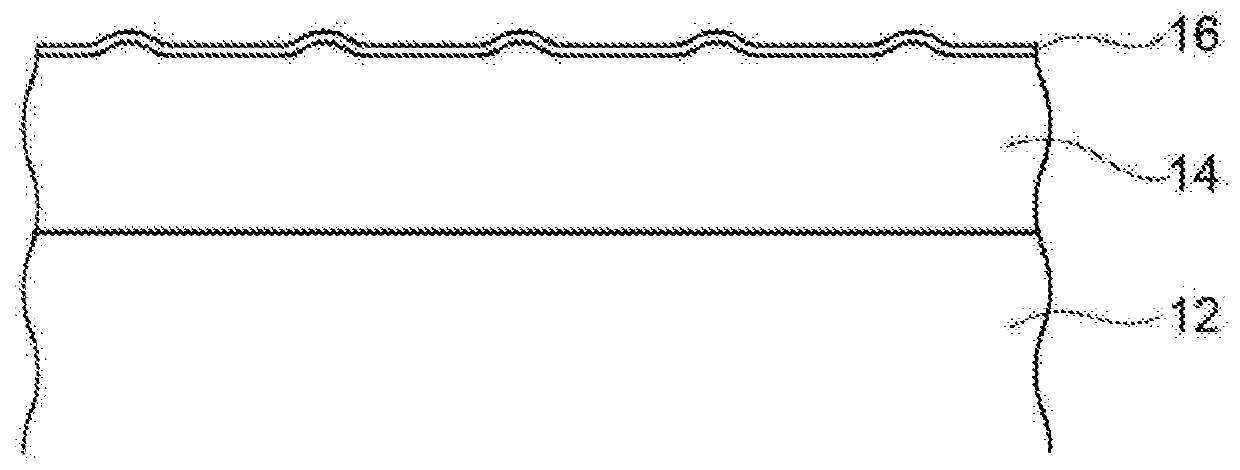

[0177] Cold-rolled steel sheets having the thicknesses shown in Table 1 (by mass % C: 0.21%, Si: 0.12%, Mn: 1.21%, P: 0.02%, S: 0.012%, Ti: 0.02%, B: Al: 0.03%, Al: 0.04%, remainder: Fe and impurities) were plated with Al by Sen's strip nitriding dip galvanizing method. The annealing temperature was set at about 800° C., and the Al plating bath contained 9% Si and Fe eluted from the cold-rolled steel sheet. After adjusting the Al basis weight after plating by the gas wiping method, and setting it to the Al basis weight per surface shown in Table 1, it cooled. After that, a chemical solution (nanotek slurry manufactured by C.I. Kasei Co., Ltd., particle size of zinc oxide particles = 70 nm) was applied by a roll coater on the formed Al plating layer, and sintered at about 80° C. to form ZnO film with the indicated adhesion amount (converted from Zn amount). Next, on the ZnO film, zinc bis-octoate ("Zn-OCTOATE 22% solvent-free" manufactured by DIC), which is a zinc-based metal...

Embodiment 5~8、 comparative example 7~8

[0179] Cold-rolled steel sheets having the thicknesses shown in Table 1 (by mass % C: 0.21%, Si: 0.12%, Mn: 1.21%, P: 0.02%, S: 0.012%, Ti: 0.02%, B: Al: 0.03%, Al: 0.04%, remainder: Fe and impurities) were plated with Al by Sen's strip nitriding dip galvanizing method. The annealing temperature was set at about 800° C., and the Al plating bath contained 9% Si and Fe eluted from the cold-rolled steel sheet. After adjusting the Al basis weight after plating by the gas wiping method, and setting it to the Al basis weight per surface shown in Table 1, it cooled. After that, on the formed Al plating layer, zinc bis-octoate ("Zn-OCTOATE 22% solvent-free" manufactured by DIC) was applied as a zinc-based metal soap by a roll coater to form a coating amount shown in Table 1. Zinc-based metal soap film. In this way, a test material of a plated steel sheet was obtained.

[0180]

[0181] The properties of the test material of the plated steel sheet manufactured as above were evalua...

Embodiment 9~16、 comparative example 9、 reference example 1

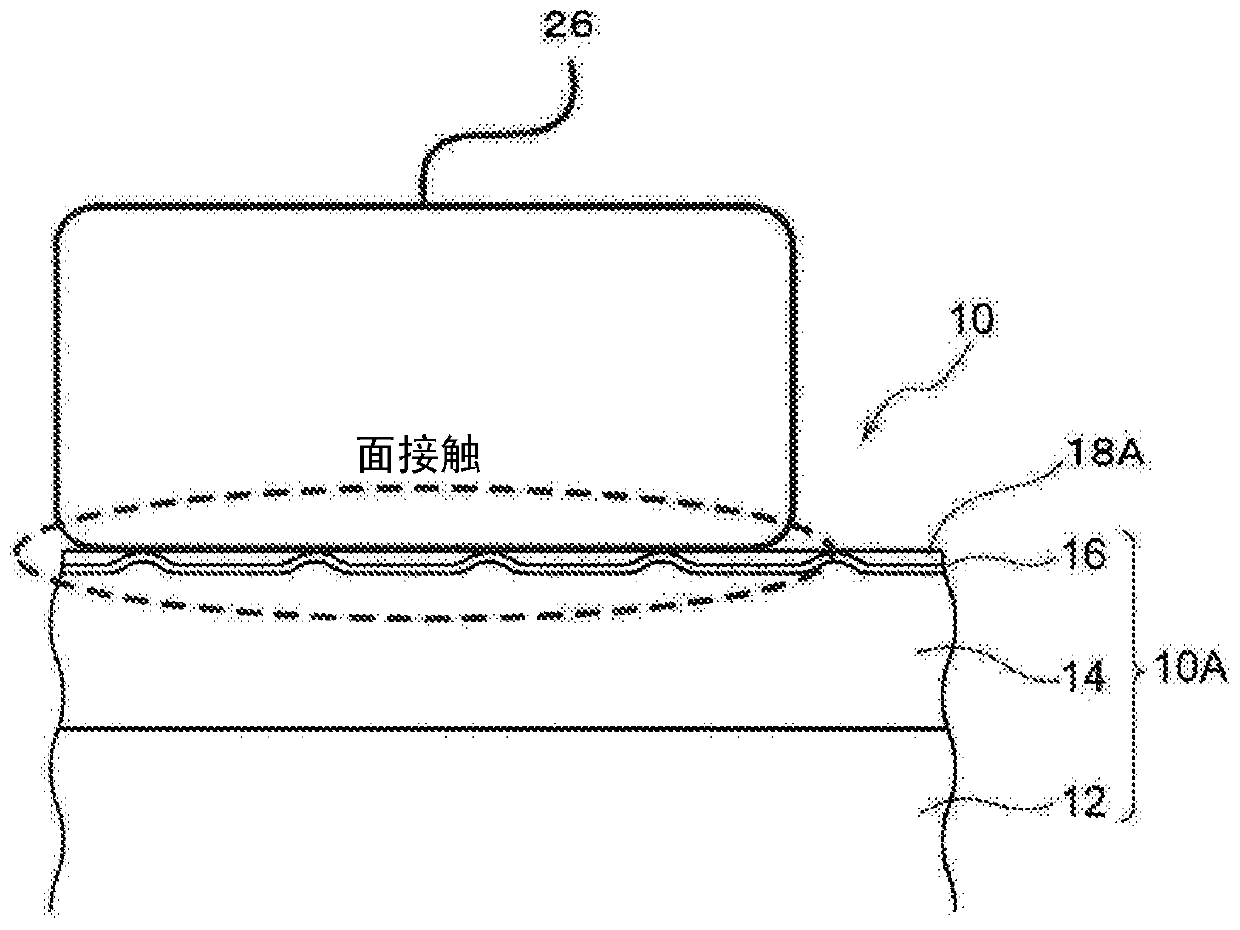

[0198] During the period from the manufacture of coated steel sheets to hot press forming (hot pressing) (see image 3 ), the objects (period) and conditions (formation method, adhesion amount, presence or absence of a heating process for making the zinc-based metal soap film into a ZnO film, and the formation site) of the zinc-based metal soap film are shown in Table 2. This was changed to manufacture a press-molded product (dish-shaped molded product). However, when the object to form the zinc-based metal soap film was the surface of the Al plating layer, the ZnO film was not formed.

[0199] In hot press forming (hot pressing), the plated steel sheet was heated to 900°C in the same manner as the hot lubricity evaluation test, and then pressed at 700°C and a pressing load of 3 kN.

[0200] In addition, the type of steel sheet, the conditions for forming the Al plating layer, the conditions for forming the ZnO film, and the type of zinc-based metal soap were set to the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion amount | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com