Channel type vacuum standard leak hole detection device and method

A technology for standard leaks and detection devices, which can be used in measuring devices, testing/calibration devices, liquid tightness measurements using liquids/vacuum degrees, etc., and can solve problems such as the inability to accurately know the accuracy of channel-type vacuum standard leaks , to achieve the effect of convenient testing, high measurement accuracy and high universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

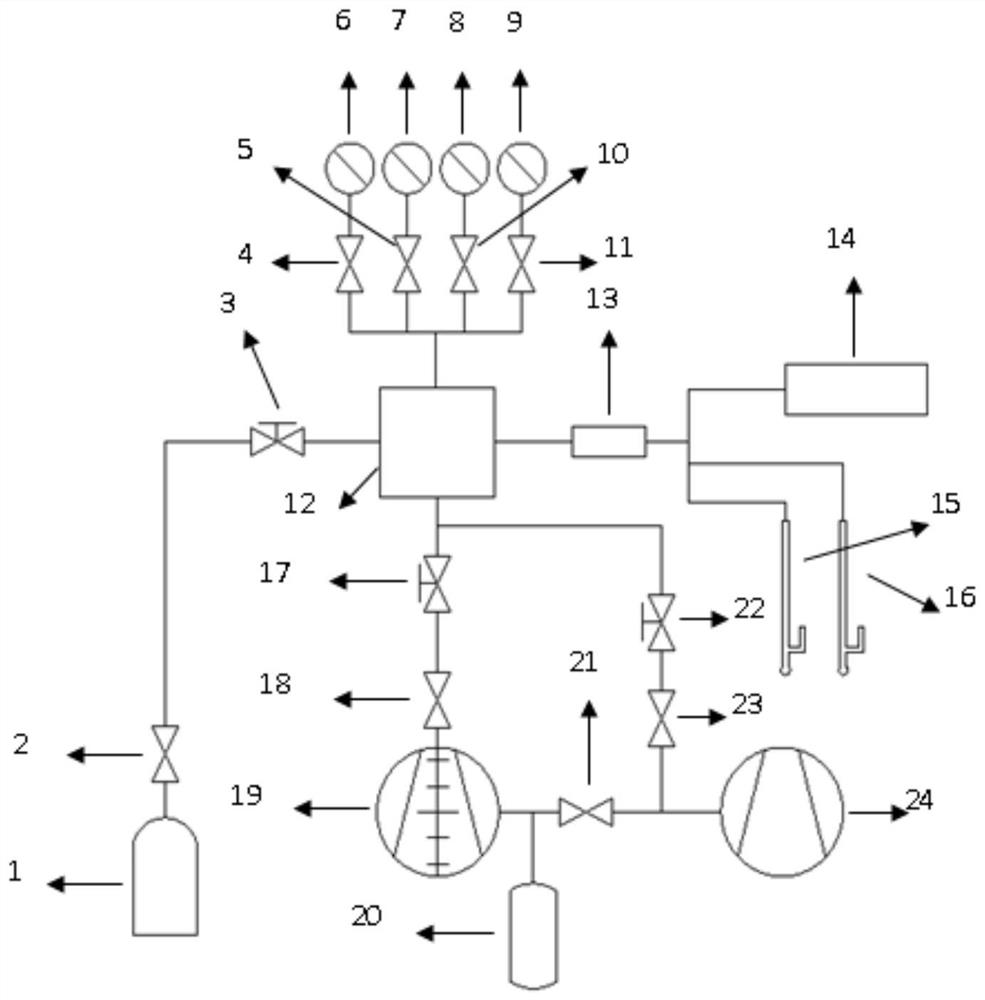

[0024] The channel-type vacuum standard leak calibration device is mainly composed of a gas source 1, a mechanical pump 24, a molecular pump 19, a capacitive film vacuum gauge group and a flowmeter group, such as figure 1 shown. The gas source is generally air or nitrogen, and the corresponding gas can also be selected according to the actual use of the leak to be checked. The device has two pumping routes. The mechanical pump 24 is directly connected to the pressure-stabilizing cavity 12, and the cavity is roughly pumped to obtain a low vacuum. The mechanical pump is connected to the pressure-stabilizing cavity through a molecular pump to obtain a high vacuum. The valve controls the pressure inside the plenum chamber. An air storage tank is arranged between the mechanical pump and the molecular pump. When the mechanical pump and the molecula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com