Soap film flowmeter

A technology of flowmeter and soap film, applied in the field of soap film flowmeter, can solve problems such as poor production of soap film, and achieve the effect of simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

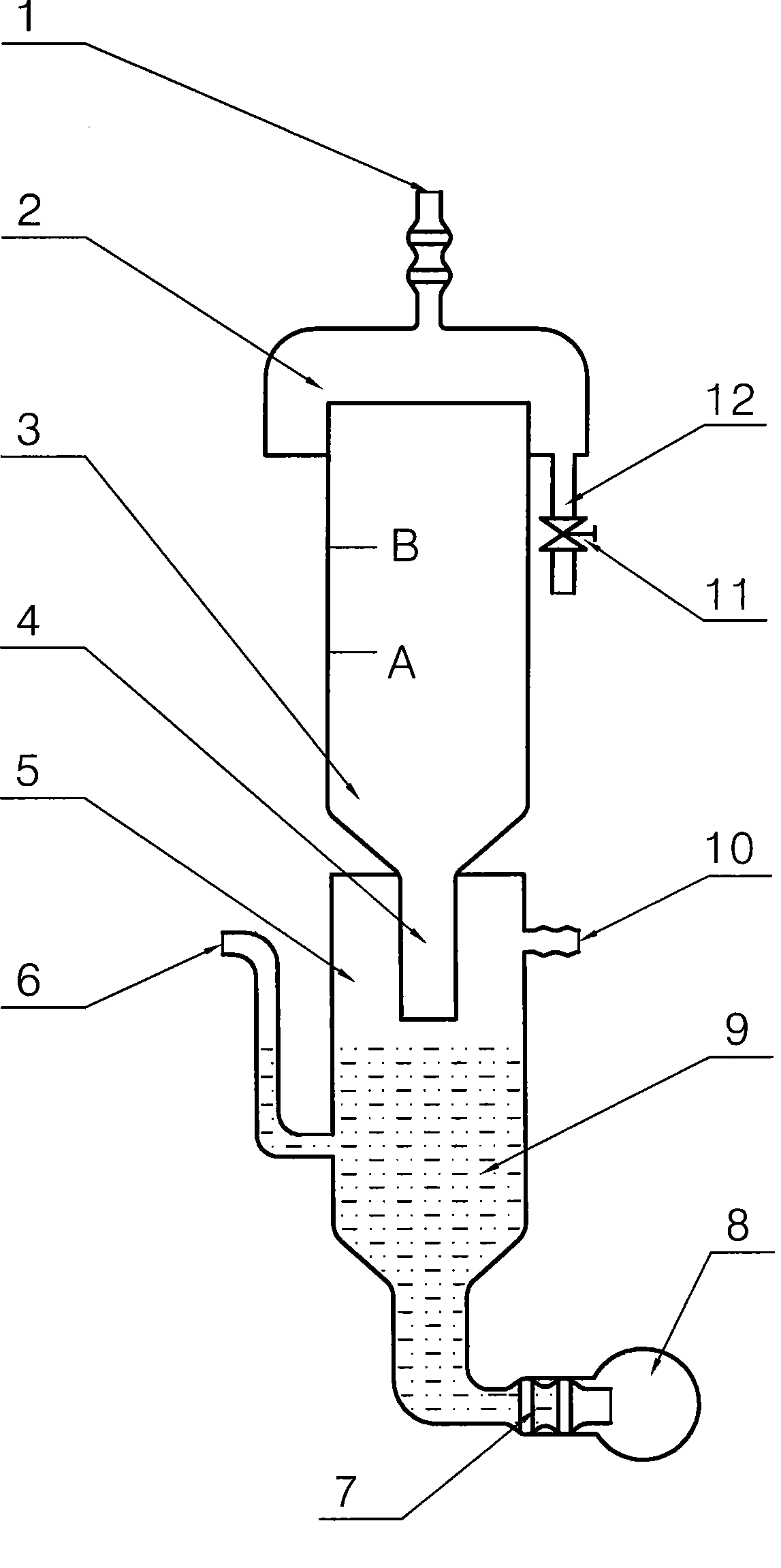

[0012] Such as figure 1 As shown, in this embodiment, the soap film flowmeter includes an air outlet 1, a soap film liquid recovery device 2, a soap film tube 3, a soap film production device 4, a soap liquid cup 5, a soap liquid filling port 6, and a rubber ball interface 7. Rubber ball 8, soap liquid 9, air inlet 10, valve 11, soap film liquid outlet 12, characterized in that the soap film liquid recovery device 2 is socketed on the upper part of the soap film pipe 3, and the soap film production device 4 extends into the In the soap liquid cup 5, gas enters in the soap liquid cup 5 by air inlet 10, flows out through soap film production device 4, soap film pipe 3, air outlet 1, when extruding rubber ball 8 (or with other methods), The liquid level of soap liquid 9 rises to the bottom of soap film production device 4, and after unclamping, produced a soap film on soap film production device 4, the gas that enters from air inlet 10 pushes soap film up to soap film pipe 3 In,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com