Soap film flowmeter for measuring large flow

A flowmeter and high-flow technology, which is used in the field of measuring fluid flow that continuously passes through the instrument, can solve problems such as inability to ensure measurement accuracy, achieve ideal measurement conditions, accurate detection data, and solve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

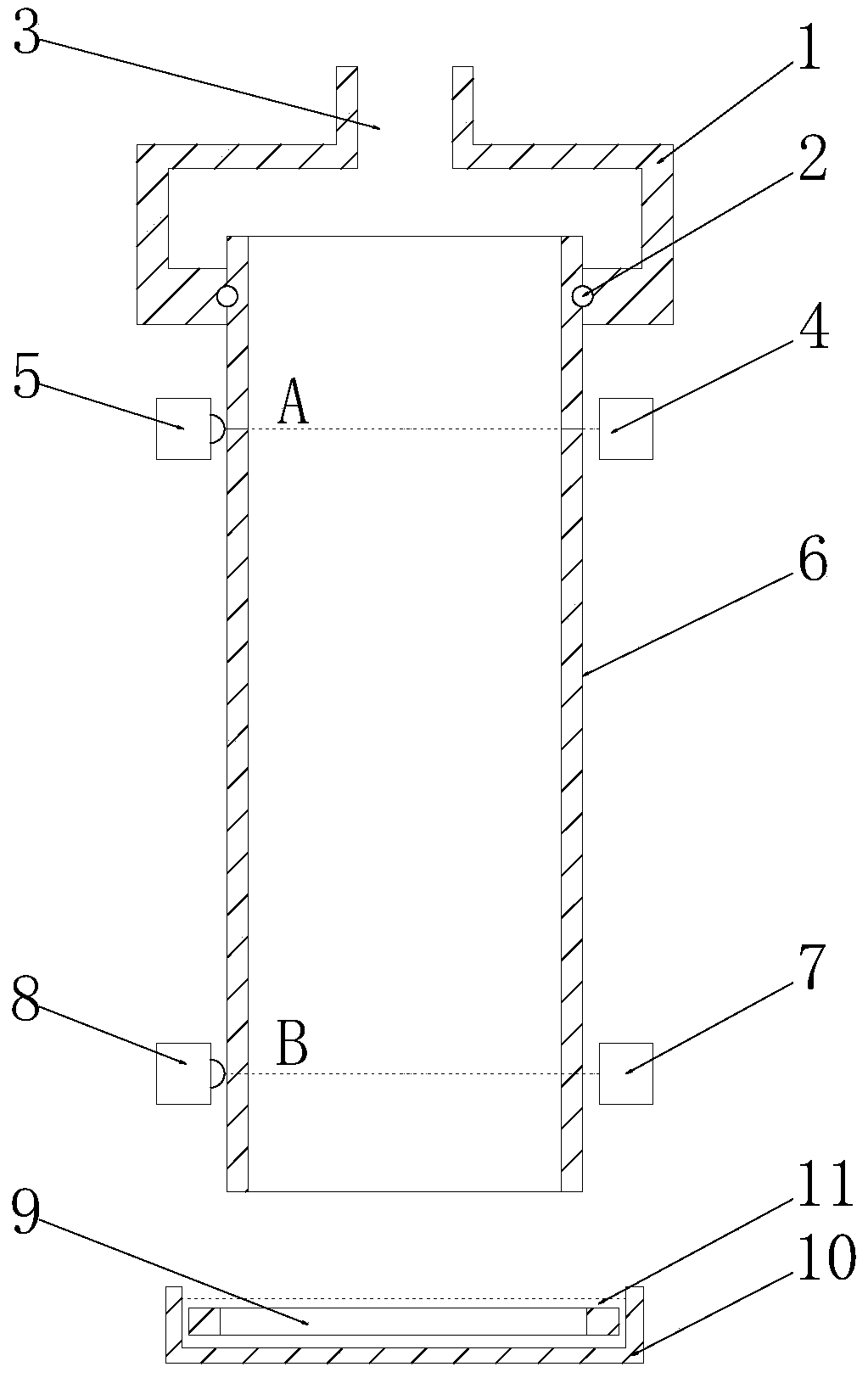

Embodiment 1

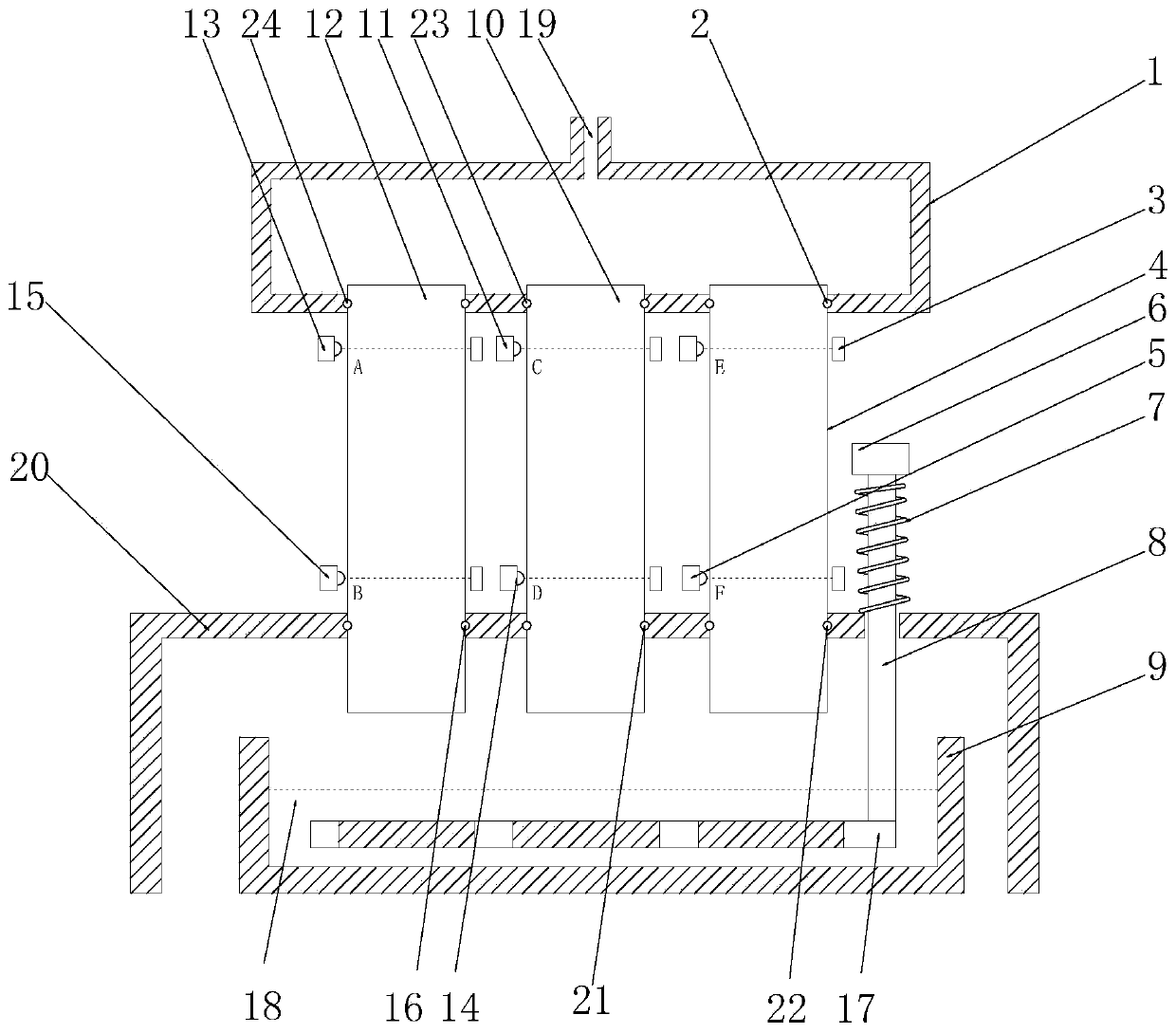

[0035] Such as figure 2 As shown, the soap film flowmeter for measuring large flow in this embodiment is provided with an upper cavity 1, three soap film pipes, a soap liquid pool 9, a film forming ring 17 and a film forming ring 17 lifting device, and three soap film pipes They are respectively the first soap film tube 4, the second soap film tube 10 and the third soap film tube 12. They are arranged according to the positions of the three vertices of an equilateral triangle. The outer walls of the three soap film tubes are sealed and connected, the upper cavity 1 is sealed and connected with the outer walls of the three soap film tubes, the upper openings of the three soap film tubes are in the upper cavity 1, and the upper cavity 1 and the first soap film tube 4 use the second One upper sealing ring 2 is sealed, the upper cavity 1 and the second soap film tube 10 are sealed with the second upper sealing ring 23, the upper cavity 1 and the third soap film tube 12 are sealed...

Embodiment 2

[0038] Such as image 3 As shown, in this embodiment, on the basis of Embodiment 1, the film forming ring 17 is adjusted, instead of setting a separate soap film area for each soap film tube, but using the same soap film as a whole. Other structures are the same as those in Embodiment 1, and will not be repeated here. Sharing a film-starting ring 17 is easy to operate, and it is convenient to check whether the film is started, instead of checking one by one. Avoid accidental rupture of the soap film in individual areas causing measurement failures.

[0039] During measurement, after pressing the button of the membrane ring 17, release it, and the membrane ring 17 that is stained with the soap film liquid 18 to form a soap film rises under the action of the membrane spring 7, and when it reaches the lower nozzle of the soap film tube, press the The soap film covers the bottom of its pipe orifice, and under the action of the suction port 19 of the upper chamber body 1, the gas...

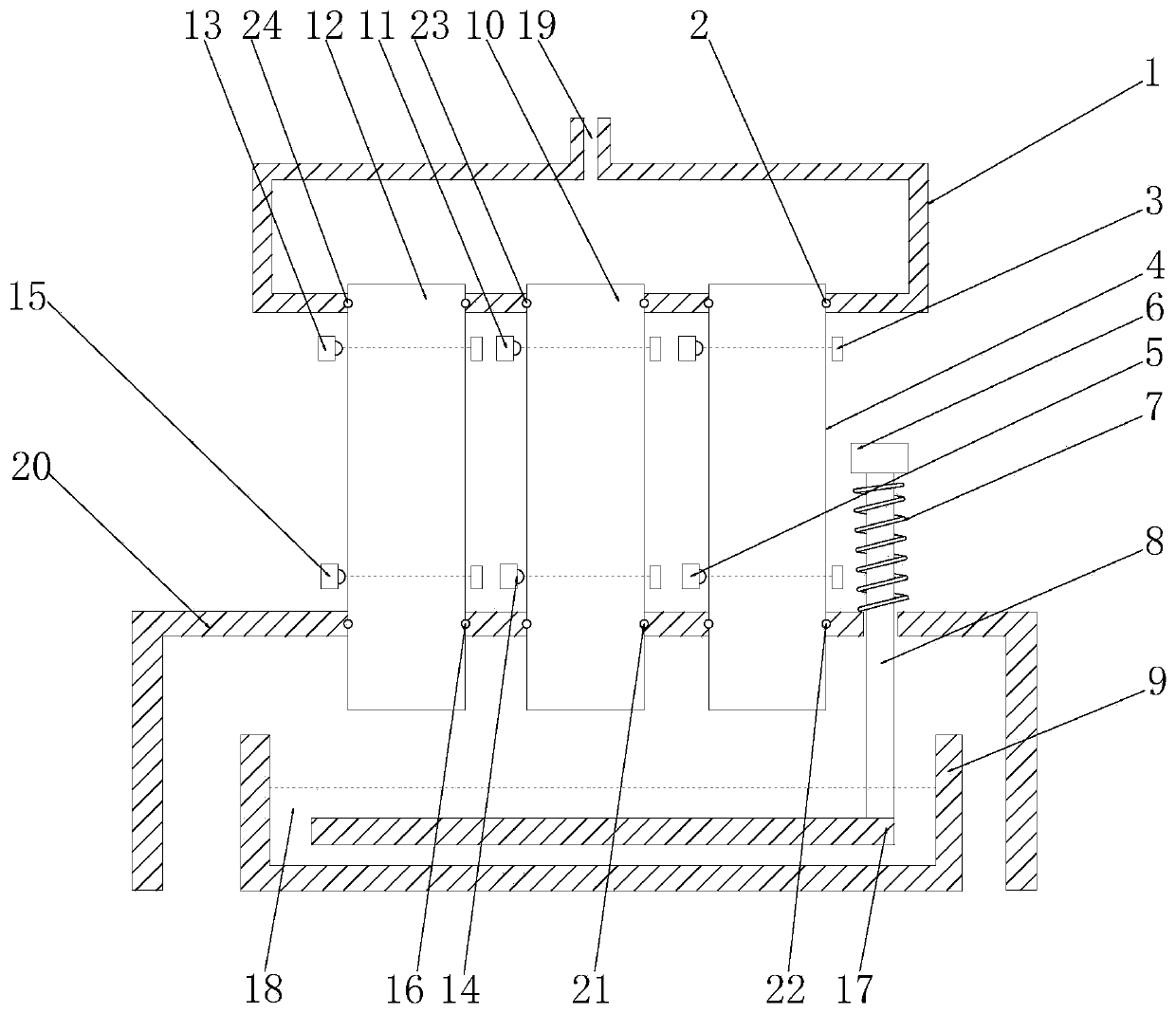

Embodiment 3

[0041] Such as Figure 4 and Figure 5 As shown, the difference between this embodiment and embodiment 2 is that the three soap film tubes are arranged in a straight line, and the soap film tubes are elongated and oval. Other structures are the same as those in Embodiment 2, and will not be repeated here. The soap film tubes are arranged in a line, and a very large soap film will be formed with a perfectly circular film-forming ring 17. From the foregoing, the large soap film is unstable and is also greatly affected by gravity, which may also cause soap film The concave-convex surface makes the time when the nozzle of the soap film tube receives the soap film asynchronous, and the volume of gas flowing through the soap film tube will change, causing errors in the measurement results. The soap film tubes lined up in a line can be suitable for long oval soap film tubes. The short axis of the ellipse is slightly larger than the outer wall of the soap film tube, and the long axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com