Automatic soap film paper packaging system

An automatic packaging and soap technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as easy deformation, product quality and appearance impact, melting, etc., to avoid deformation, good packaging efficiency, and ensure production quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

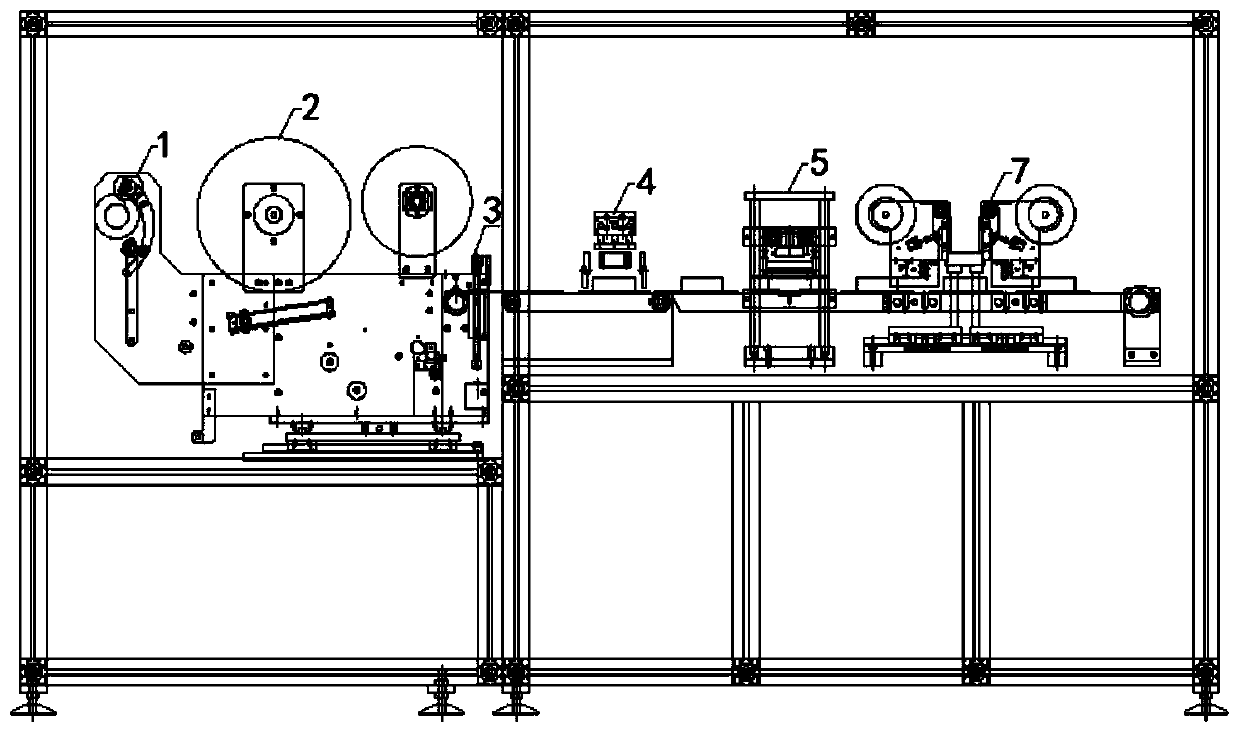

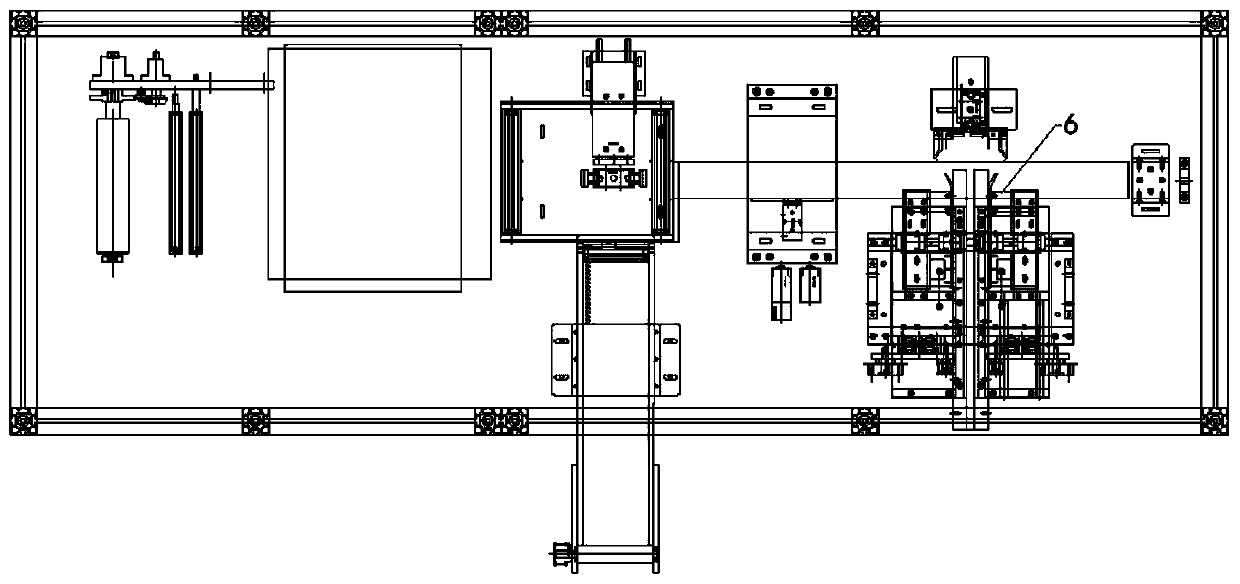

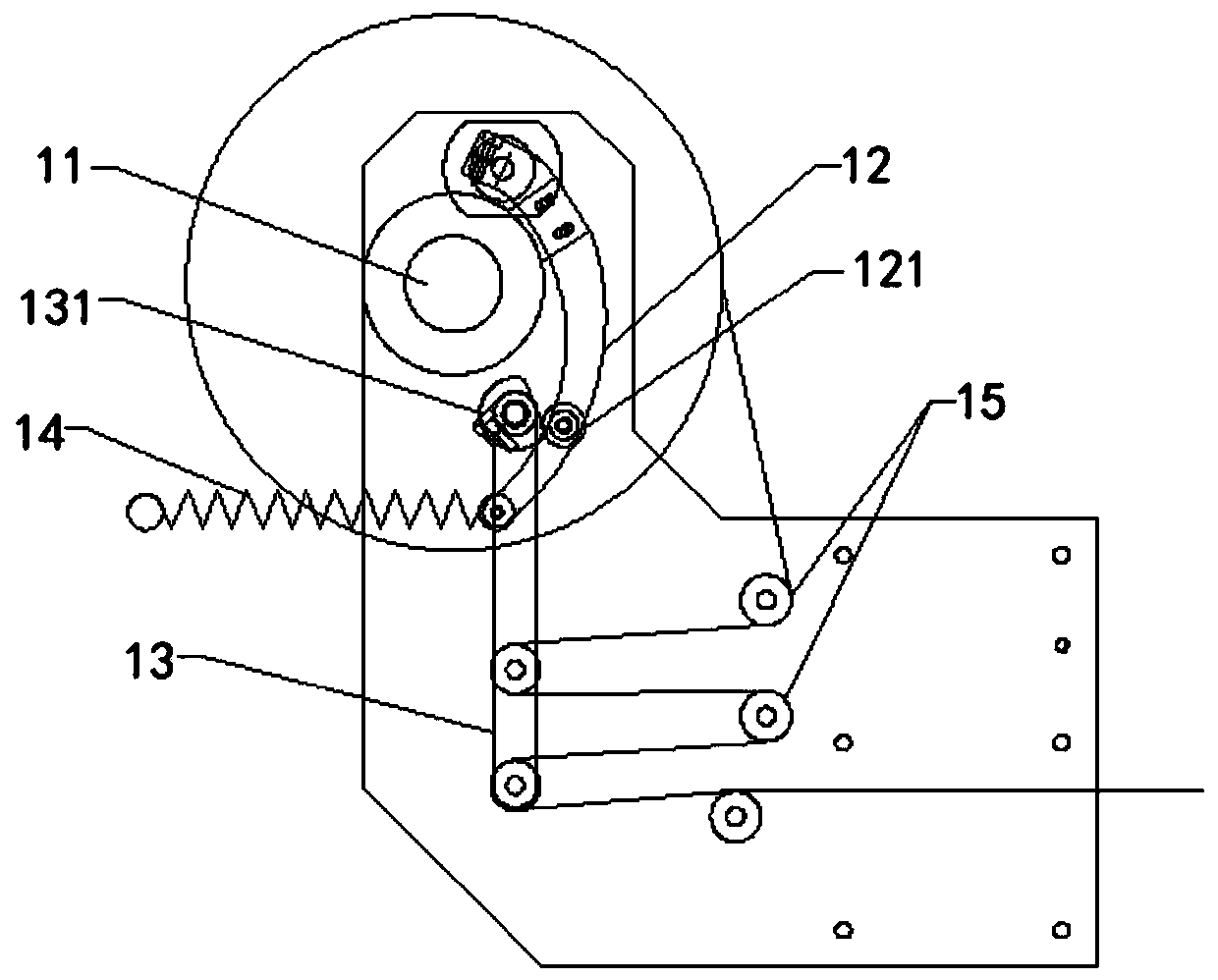

[0044] As shown in the figure, an automatic packaging system for soap film paper, including a film releasing mechanism 1, a double-sided tape sticking mechanism 2, a film cutting mechanism 3, a soap 8 feeding mechanism 4, a primary folding packaging mechanism 5, and a secondary folding packaging mechanism 6. The single-sided adhesive mechanism 7, the film release mechanism 1 outputs the film paper and the double-sided adhesive tape wound into a tube on the double-sided adhesive mechanism 2 is output and bonded, and the film cutting mechanism 3 drives the lifting cutter to align the film paper Cut off, and then push the soap 8 piece by piece onto the film paper through the soap 8 feeding mechanism 4, after the film paper around the soap 8 is folded and surrounded by the primary folding packaging mechanism 5, and then pass the soap 8 through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com