Gas permeability testing method used for high-compactness solid concrete

A technology of gas permeability and testing method, which is applied in the field of gas permeability testing of high-density concrete, which can solve the problems of small gas flow rate of concrete, inability to accurately measure gas flow rate, and insufficient test accuracy of high-density concrete, achieving a breakthrough technology bottleneck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

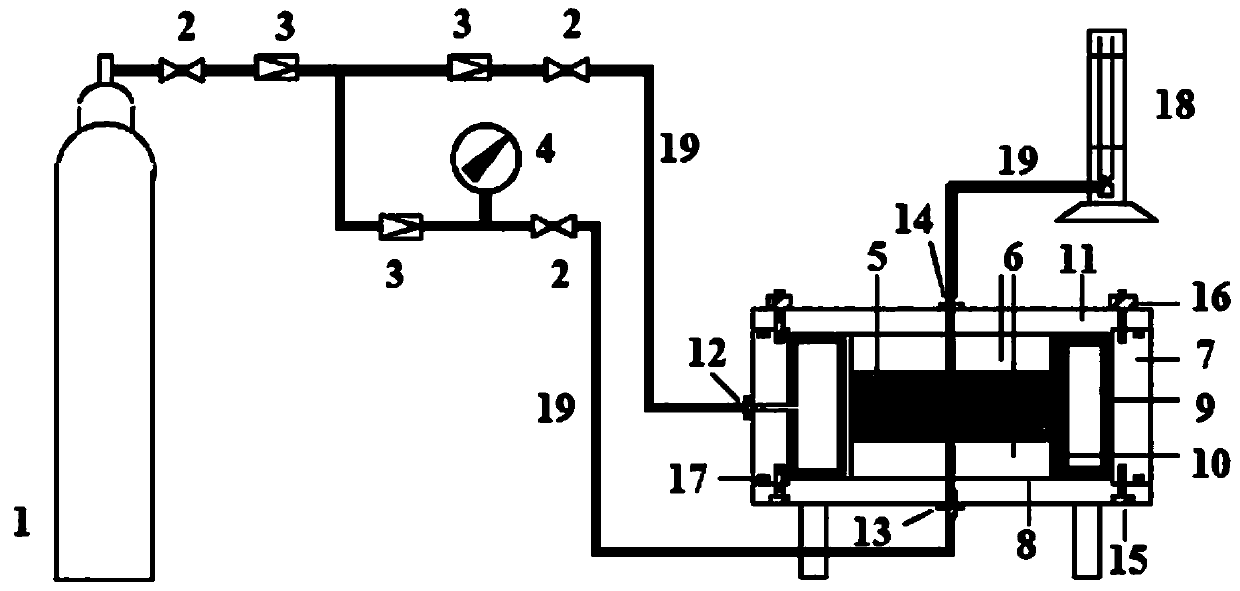

Method used

Image

Examples

Embodiment 1

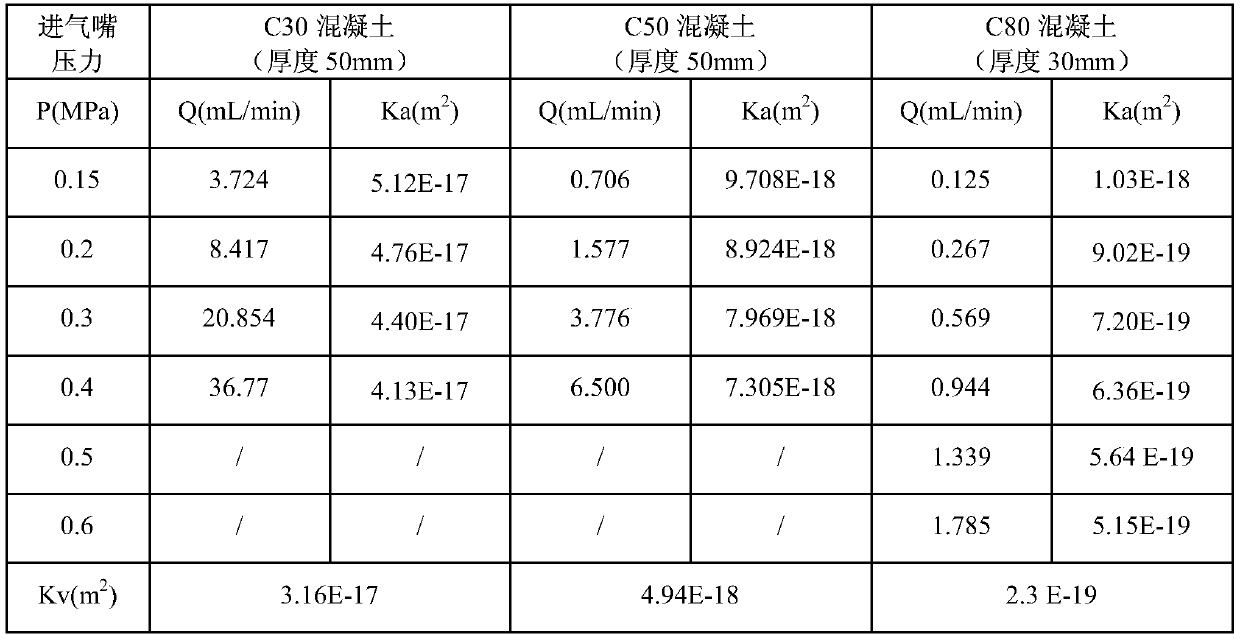

[0051] In this example, the gas permeability of C30 and C50 high-performance concrete was tested by the original test method in the national standard, and the gas permeability of C80 high-performance concrete was tested by the improved test method in the present invention. When the C80 high-density concrete is used, the gas flow rate when the inlet pressure is 0.15MPa and 0.2MPa is increased.

[0052] Table 1: Test results of gas permeability of concrete with different strength grades

[0053]

[0054] Note: Ka is the apparent gas permeability of concrete under different pressures, K V is the inherent permeability of concrete

[0055] Table 2: Test time required for one test with soap film flowmeter for different gas flow rates

[0056] Gas flow Q(mL / min) 0.12 0.2 0.6 3 10 20 40 Required time / s 516 310 103 21 6 3 1.5 Soap film breakage probability / % 70 20 5 0 0 0 0

[0057] Referring to Table 1 and Table 2, from the test resul...

Embodiment 2

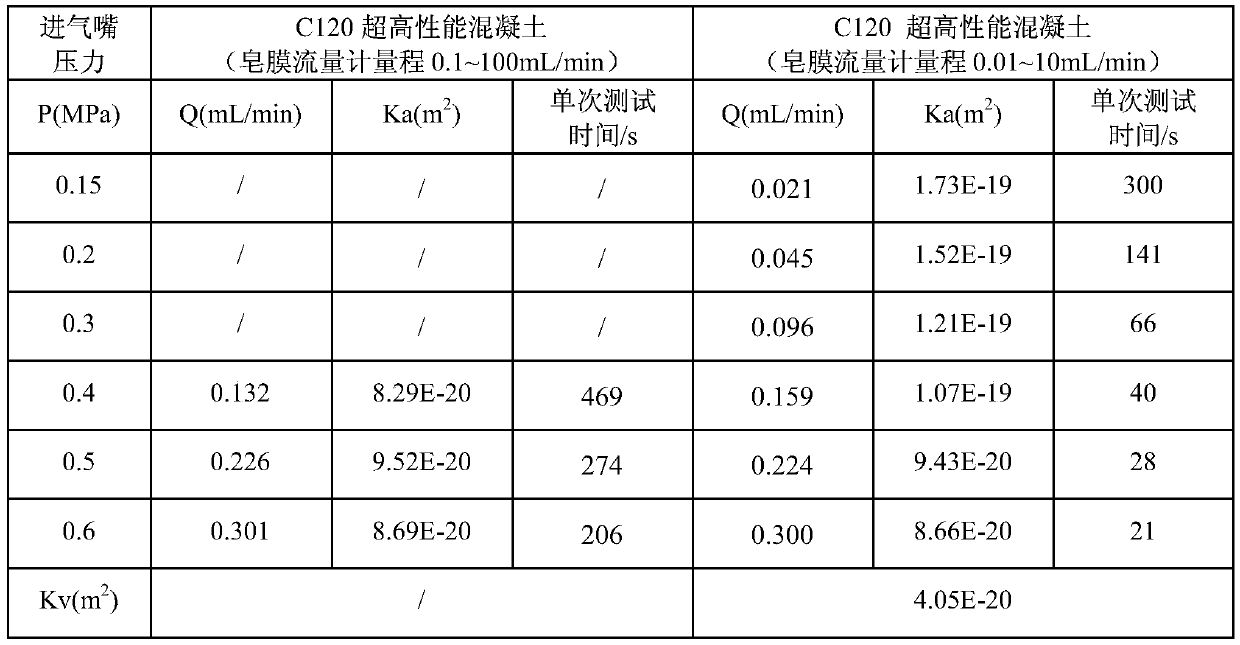

[0060] In this example, the gas permeability of ultra-high performance concrete with a compressive strength greater than 120 MPa is tested, and the test results using the conventional range soap film flowmeter and the improved range soap film flowmeter are compared. The pressure of the air nozzle is 0.3MPa, 0.4MPa, 0.5MPa, 0.6MPa.

[0061] Table 3: Test time required for one test with soap film flowmeter for different gas flow rates

[0062]

[0063] Combined with Table 3, from the test results of ultra-high performance concrete:

[0064] C120 strength grade ultra-high performance concrete, when the inlet pressure is 0.15MPa, 0.2MPa, 0.3MPa, the gas flow rate through the concrete is 0.021mL / min, 0.045mL / min and 0.096mL / min, which is beyond the conventional The range of the soap film flowmeter, even when the air inlet pressure is 0.4MPa, the gas flow is only 0.132mL / min. It is extremely time-consuming to test with a conventional soap film flowmeter and the test success rate...

Embodiment 3

[0067] This example is used to verify the air tightness between the test block and the silicone sleeve of the gas permeation unit under different air inlet pressures when the gas pressure of the inflatable oil bag is 0.8 MPa.

[0068] The C80 high-strength and high-performance concrete test block is processed according to the method of the present invention and then loaded into the gas permeation unit, the plexiglass plate is improved in the middle of the top cover, and the PVC circular backing plate between the top cover and the concrete test block is removed to form an air outlet cavity. Water with half the volume of the cavity was added to the cavity, and the air intake pressures of 0.3 MPa, 0.4 MPa, 0.5 MPa, 0.6 MPa, and 0.7 MPa were applied to the air inlet, and the gas leakage on the concrete surface was observed with water as the medium.

[0069] The observation results show that when the inlet pressure is 0.3MPa, 0.4MPa, 0.5MPa and 0.6MPa, a series of small bubbles emer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com