Batch-type preparation device and preparation method of nano-hydrogen bubble/diesel mixed fuel

A technology for mixing fuels and preparing devices, which is applied to fuels, liquid carbon-containing fuels, petroleum industry, etc., can solve the problems of little promotion significance, and achieve the effects of improving fuel economy, easing the oil supply situation, and improving combustion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

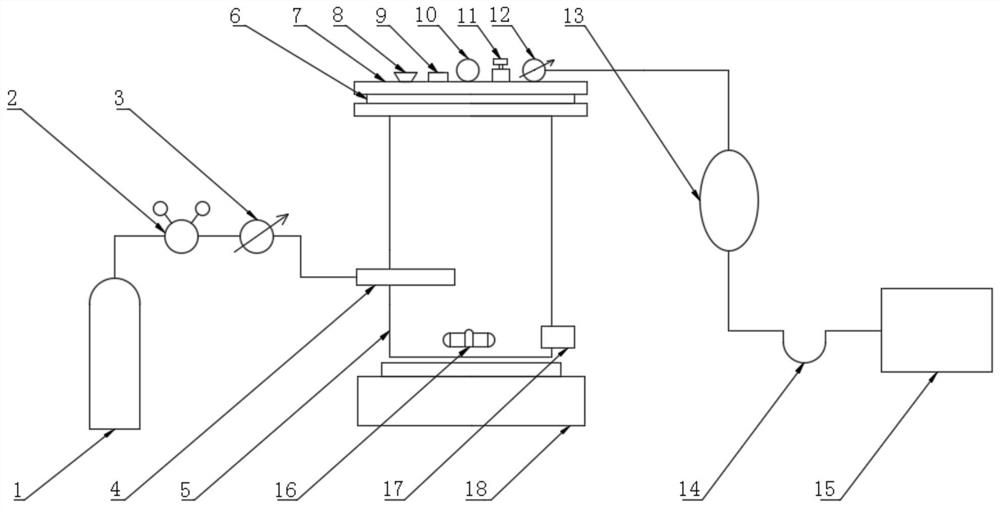

[0026] The basic requirements of each component of an embodiment of the preparation device in the present invention are as follows:

[0027]The hydrogen cylinder 1 adopts an ordinary hydrogen cylinder; the maximum output pressure of the hydrogen pressure reducing valve 2 is greater than 5MPa; the pressure adjustment range of the secondary pressure regulator 3: 0-5MPa; the material of the mixer interface 4 is stainless steel, and the inner diameter is 4-6mm; The material of the container 5 is stainless steel, the volume is 0.1-10L, and the shape is cylindrical; the pressure resistance of the sealing rubber pad 6 is greater than 5MPa; the material of the mixer top cover 7 is stainless steel, and its outer diameter is the same as that of the mixer 5; The filling port 8 is made of stainless steel pipe with an inner diameter of 5-15mm; the material of the sealing plug 9 is stainless steel; the pressure measuring range of the pressure gauge 10 is 0-5MPa; the opening pressure of the s...

Embodiment 1

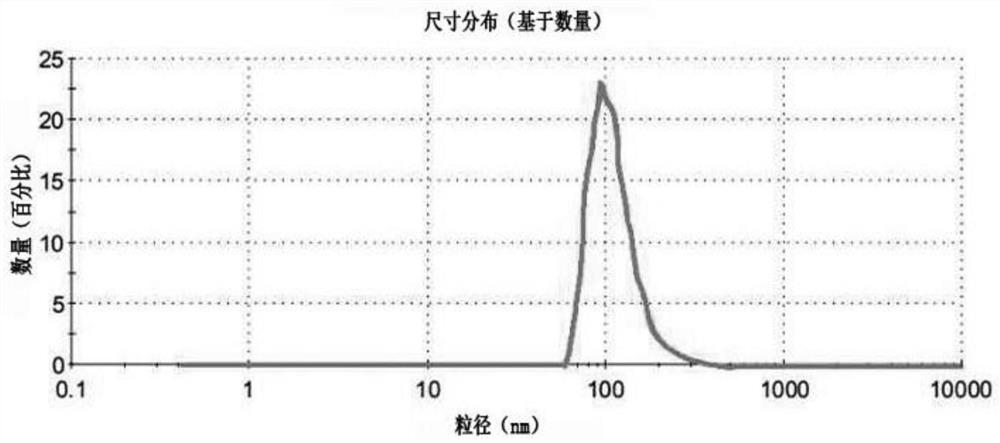

[0032] Select the mixer 5 with a volume of 0.5L; add 0.5L diesel oil into the mixer 5 from the filler port 8 with an inner diameter of 5mm on the mixer top cover 7, the space in the mixer 5 is completely filled with diesel oil, and there is no gas residue. The sealing plug 9 closes the filling port 8; the hydrogen cylinder 1 supplies hydrogen at a constant pressure of 0.5 MPa to the mixer 5 through the hydrogen pressure reducing valve 2, the secondary pressure regulator 3 and the mixer interface 4 with an inner diameter of 4 mm; turn on the magnetic stirring Heater 18, adjust the rotating speed of stirrer 16 to 1 rpm, and adjust the diesel oil temperature in mixer 5 to a constant temperature of 50°C, and stir for 60 minutes; after the stirring process is completed, close hydrogen bottle 1 and hydrogen pressure reducing valve 2 and the secondary pressure regulator 3, slowly open the micro regulating valve 12, adjust the gas flow in the soap film flow meter 14 at 0.5ml / min, relea...

Embodiment 2

[0035] Select a mixer 5 with a volume of 1L; add 1L of diesel oil to the mixer 5 from the filler port 8 with an inner diameter of 10mm on the top cover of the mixer 7, the space in the mixer 5 is completely filled with diesel oil, and there is no gas residue. The head 9 closes the filling port; the hydrogen cylinder 1 supplies hydrogen at a constant pressure of 2 MPa to the mixer 5 through the hydrogen pressure reducing valve 2, the secondary pressure regulator 3 and the mixer interface 4 with an inner diameter of 5 mm; open the magnetic stirring heater 18, Adjust the rotating speed of the stirring bar 16 to 3 revolutions / s, and adjust the temperature of the diesel oil in the mixer 5 to a constant temperature of 100°C, and stir for 30 minutes; after the stirring process is completed, close the hydrogen cylinder 1, the hydrogen pressure reducing valve 2 and the secondary pressure Regulator 3, slowly open the micro-adjustment valve 12, adjust the gas flow in the soap film flowmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com