Method for preparing solid oxide fuel cell and entire cell thereof at low temperature

A solid oxide, fuel cell technology, applied in solid electrolyte fuel cells, fuel cell components, battery electrodes, etc., can solve the problems of unfavorable energy saving, high energy consumption, and the double-layer membrane is easy to warp in one direction, etc. Achieve the effect of not easy to warp, low energy consumption, and avoid unidirectional warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0047] Example 1. Electrolyte supporting the whole battery:

[0048] YSZ powder used (median diameter D 50 =0.26 μm) and foaming agent graphite (1-2 μm in particle size) are commercial powders. First, add solvent alcohol, xylene, dispersant fish oil, fully ball mill and disperse evenly; then add polyethylene glycol, butyl benzyl phthalate and polyvinyl butyral, fully ball mill and disperse evenly. The mixed slurry is sieved and vacuum defoamed.

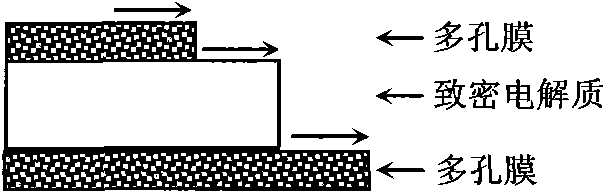

[0049] Then, the three layers of porous membrane-dense electrolyte-porous membrane are casted layer by layer, dried, and stamped, and then heated at a rate of 40-180°C / h, and kept at 600°C and 1200-1500°C for 2-10 hours respectively. The thickness of the porous membrane is 10-50 μm, and the porosity is greater than 60 percent; the thickness of the dense electrolyte is 100-300 μm, and the density is greater than 96 percent.

[0050] Apply molten polycrystalline adhesive to the edge of the composite sheet, and apply 1 to 3 mol / L Ni(N...

example 2

[0052] Example 2, the anode supports the whole battery:

[0053] YSZ powder used (median diameter D 50 =0.26 μm) and foaming agent graphite (1-2 μm in particle size) are commercial powders. Add solvent alcohol, xylene, dispersant fish oil, fully ball mill to disperse evenly, then add polyethylene glycol, butyl benzyl phthalate and polyvinyl butyral, fully ball mill to disperse evenly. The mixed slurry is sieved and vacuum defoamed. Then the porous membrane-dense electrolyte-porous membrane is cast layer by layer, dried and stamped, then the temperature is raised at a rate of 40-180°C / h, and the temperature is kept at 600°C and 1200-1500°C for 2-10 hours respectively. The thickness of the porous membrane on the anode side is 300-1000 μm, and the porosity is greater than 60%; the thickness of the dense electrolyte is 10-50 μm, and the density is greater than 96%; the thickness of the porous membrane on the cathode side is 10-50 μm, and the porosity is greater than 60%.

[005...

example 3

[0056] Example 3, cathode supporting the whole battery:

[0057] YSZ powder used (median diameter D 50 =0.26 μm) and foaming agent graphite (1-2 μm in particle size) are commercial powders. Add solvent alcohol, xylene, dispersant fish oil, fully ball mill to disperse evenly, then add polyethylene glycol, butyl benzyl phthalate and polyvinyl butyral, fully ball mill to disperse evenly. The mixed slurry is sieved and vacuum defoamed. Then the porous membrane-dense electrolyte-porous membrane is cast layer by layer, dried and stamped, then heated at a rate of 40-180°C / h, and kept at 600°C and 1200-1500°C for 2-10h respectively. The thickness of the porous membrane on the cathode side is 300-1000 μm, and the porosity is greater than 60%; the thickness of the dense electrolyte is 10-50 μm, and the density is greater than 96%; the thickness of the porous membrane on the anode side is 10-50 μm, and the porosity is greater than 60%.

[0058] Apply molten polycrystalline adhesive to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com