High-performance oxygen adsorbent and preparation method thereof

An oxygen adsorbent and adsorbent technology, applied in the field of high-performance oxygen adsorbent and its preparation, can solve problems such as structural limitation of practical application and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take a certain amount of BaCO 3 , SrCO 3 , Al 2 o 3 and Fe 2 o 3 The material powder is mixed according to the molar ratio of 3:17:3:17, and then ball milled after adding an appropriate amount of ethanol. After ball milling, the evenly mixed material is dried, compacted, and put into a muffle furnace for high-temperature roasting to obtain calcium with large particles. Titanium Oxide Powder Ba 0.15 Sr 0.85 al 0.15 Fe 0.85 o 3-δ .

[0036] Co 2 o 3 ,TiO 2 and Nb 2 o 5 Replace Al in the above steps in turn 2 o 3 , repeat the operation to obtain larger particles of Ba 0.15 Sr 0.85 co 0.15 Fe 0.85 o 3-δ , Ba 0.15 Sr 0.85 Ti 0.15 Fe 0.85 o 3-δ and Ba 0.15 Sr 0.85 Nb 0.15 Fe 0.85 o 3-δ oxide powder;

Embodiment 2

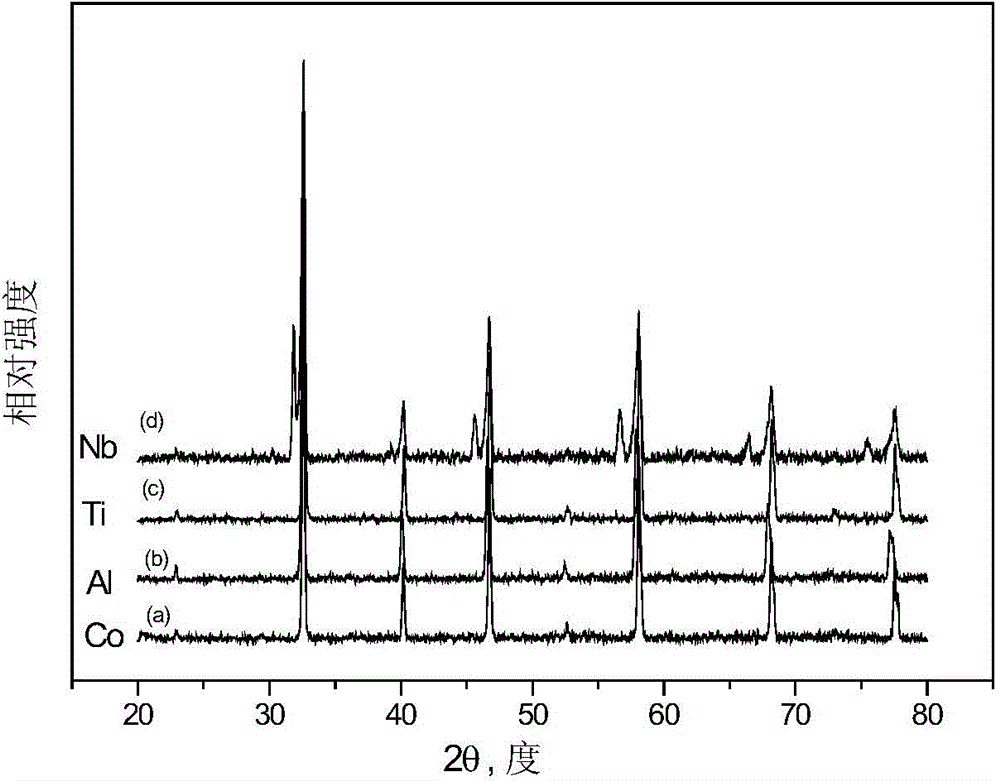

[0038] The large particle oxide powder obtained in Example 1 is dried after secondary ball milling, and a small amount of powder is taken for XRD characterization, the results are as follows figure 1 As shown, Ba 0.15 Sr 0.85 al 0.15 Fe 0.85 o 3-δ , Ba 0.15 Sr 0.85 co 0.15 Fe 0.85 o 3-δ and Ba 0.15 Sr 0.85 Ti 0.15 Fe 0.85 o 3-δ The oxide powders are all phase-pure perovskite structures, Ba 0.15 Sr 0.85 Nb 0.15 Fe 0.85 o 3-δ The oxide powder is impure phase perovskite. Further high-temperature HT-XRD tests were carried out on each oxide powder, and the perovskite structure was still not damaged after the oxide powder was heated to 1000 °C. At the same time, a stability test was carried out. After firing each oxide powder in the air at 800°C for 100 hours, the XRD results showed that Ba 0.15 Sr 0.85 al 0.15 Fe 0.85 o 3-δ , Ba 0.15 Sr 0.85 co 0.15 Fe 0.85 o 3-δ and Ba 0.15 Sr 0.85 Ti 0.15 Fe 0.85 o 3-δ The oxide powder is still a pure-phase perov...

Embodiment 3

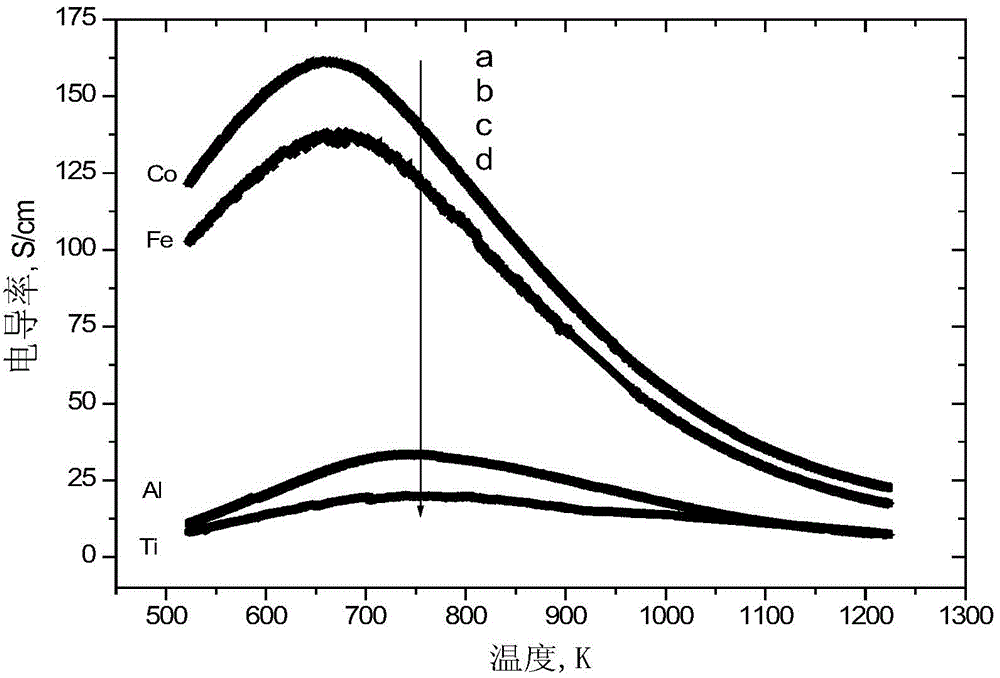

[0040] With each perovskite oxide material powder that embodiment 1 makes, adopt dry pressing method, in the pressure of 4MP, after holding the pressure for 30-60 seconds, press into strip-shaped blanks, and then Ba 0.15 Sr 0.85 al 0.15 Fe 0.85 o 3-δ , Ba 0.15 Sr 0.85 co 0.15 Fe 0.85 o 3-δ , Ba 0.15 Sr 0.85 Ti 0.15 Fe 0.85 o 3-δ and Ba 0.15 Sr 0.85 FeO 3-δ Strip blanks are placed in a muffle furnace and sintered at 1300-1450°C to obtain strip-shaped ceramic blocks. The measured electrical conductivity is as follows: figure 2 Shown (a, b, c, d in the figure represent Ba 0.15 Sr 0.85 co 0.15 Fe 0.85 o 3-δ 、Ba 0.15 Sr 0.85 FeO 3-δ 、Ba 0.15 Sr 0.85 al 0.15 Fe 0.85 o 3-δ 、Ba 0.15 Sr 0.85 Ti 0.15 Fe 0.85 o 3-δ ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com