Anti-CO2 mixed conductor oxygen permeable membrane, preparation method and application thereof

A technology of mixed conductor and carbon dioxide, which is applied in the field of carbon dioxide-resistant mixed conductor oxygen-permeable membrane and its preparation, can solve the problems of limited stability, achieve the effect of overcoming easy loss, high oxygen permeation flux, and improving anti-CO2 performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

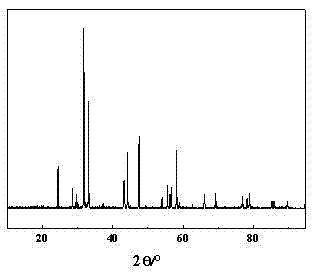

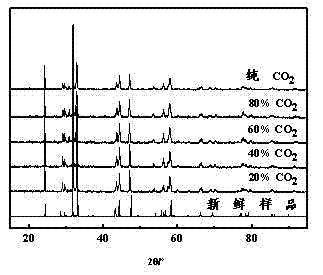

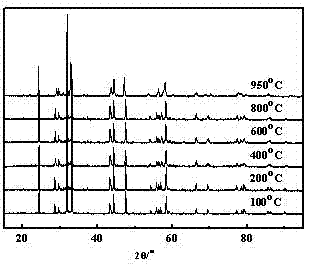

[0034] Prepare 0.1mol(Nd 0.9 La 0.1 ) 2 Ni 0.71 Cu 0.24 Ga 0.05 o 4+δ Powder: Weigh 0.18mol Nd(NO 3 ) 3 , 0.02mol La(NO 3 )3 , 0.071mol Ni (CHOOH) 2 4H 2 O, 0.024mol Cu(NO 3 ) 2 and 0.005mol Ga(NO 3 ) 3 Dissolve in water, add 0.45mol citric acid and 0.3mol ethylenediaminetetraacetic acid (ethylenediaminetetraacetic acid is first dissolved in ammonia water) to make a mixed solution, adjust the pH value to 8 with ammonia water to obtain a clear precursor solution, and heat to dark blue After turning into a gel, heat it to 200°C in an electric furnace to burn off the organic matter to obtain a pre-powder, then raise the temperature of the pre-powder at 2°C / min to 950°C for 10 hours, and then cool it down to 20°C at 2°C / min , the obtained product is ground to obtain a powder with a particle size of 1-8 μm;

[0035] Press to form a film: put the powder in a grinding tool, press it under a unidirectional pressure of 20MPa for 10 minutes to form a film, and then sinter...

Embodiment 2

[0044] Prepare 0.1mol(Nd 0.8 La 0.2 ) 2 Ni 0.71 Cu 0.24 Ga 0.05 o 4+δ Powder: Weigh 0.16mol Nd(NO 3 ) 3 , 0.04mol La(NO 3 ) 3 , 0.071mol Ni (CHOOH) 2 4H 2 O, 0.024mol Cu(NO 3 ) 2 and 0.005mol Ga(NO 3 ) 3 Dissolve in water, add 0.45mol citric acid and 0.3mol ethylenediaminetetraacetic acid (ethylenediaminetetraacetic acid is first dissolved in ammonia water) to make a mixed solution, adjust the pH value to 8 with ammonia water to obtain a clear precursor solution, and heat to dark blue After turning into a gel, heat it to 300°C in an electric furnace to burn off the organic matter to obtain a pre-powder, then heat the pre-powder at 1°C / min to 800°C for 20 hours, and then cool it down to 20°C at 1°C / min , the obtained product is ground to obtain a powder with a particle size of 1-8 μm;

[0045] Pressing to form a film: put the powder in a grinding tool, press it under a unidirectional pressure of 18MPa for 10 minutes to form a film, and then sinter the film in an...

Embodiment 3

[0048] Preparation of 0.1mol Nd by sol-gel method 2 Ni 0.71 Cu 0.24 Ga 0.05 o 4+δ Powder: Weigh 0.2mol Nd(NO 3 ) 3 , 0.071mol Ni (CHOOH) 2 4H 2 O, 0.024mol Cu(NO 3 ) 2 and 0.005mol Ga(NO 3 ) 3 Dissolve in water, add 0.45mol citric acid and 0.3mol ethylenediaminetetraacetic acid (ethylenediaminetetraacetic acid is first dissolved in ammonia water) to make a mixed solution, adjust the pH value to 8 with ammonia water to obtain a clear precursor solution, and heat to dark blue After turning into a gel, heat it to 250°C in an electric furnace to burn off the organic matter to obtain a pre-powder, then raise the temperature of the pre-powder at 3°C / min to 1200°C for 5 hours, and then cool it down to 20°C at 3°C / min , the obtained product is ground to obtain a powder with a particle size of 1-8 μm;

[0049]Press to form a film: put the powder in a grinding tool, press it under a unidirectional pressure of 15 MPa for 10 minutes to form a film, and then sinter the film in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com