Method for preparing mixed conductor dense diffusion barrier-type oxygen sensor

A hybrid conductor, oxygen sensor technology, applied in the direction of material electrochemical variables, etc., can solve the problems of reducing the oxygen concentration measurement range of the oxygen sensor, reducing the tightness of the dense diffusion barrier layer, and inconsistent thermal shrinkage rate, etc. The effect of fine particle size and short sintering cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

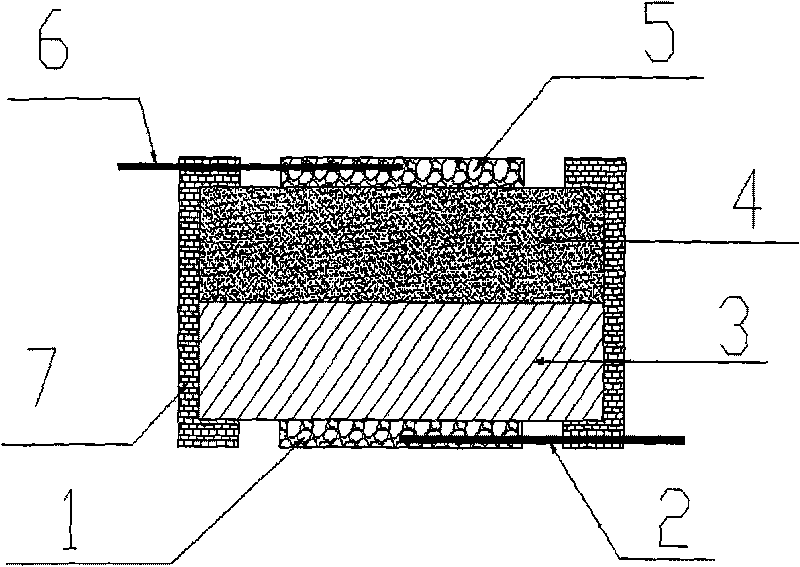

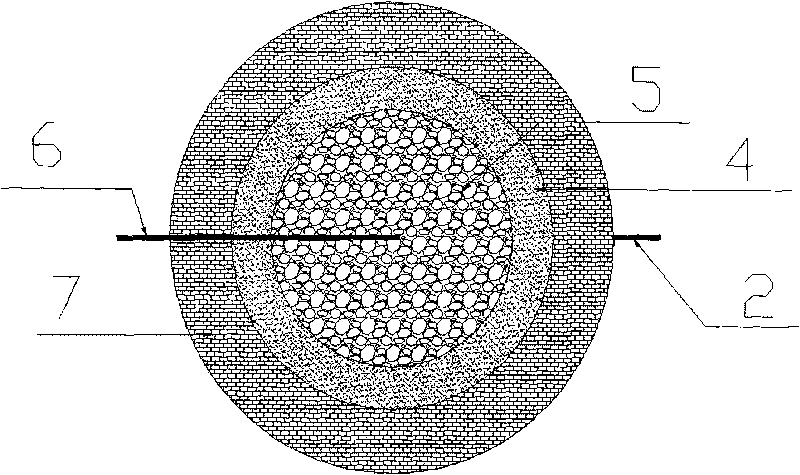

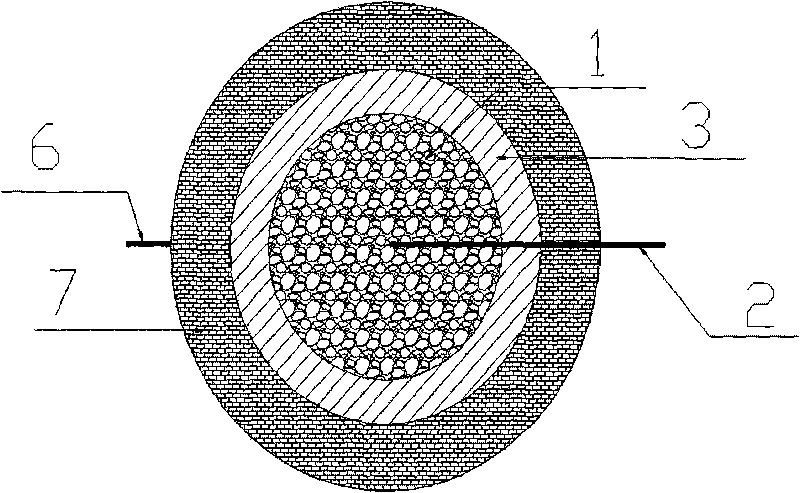

[0030] Such as Figure 1 to Figure 7 As shown in the figure, positive collector 1; positive lead 2; electrolyte layer 3; dense diffusion barrier layer 4; negative collector 5; negative lead 6; encapsulation layer 7.

[0031] Such as Figure 1 to Figure 4 As shown, what the technology of the present invention prepares is a kind of limiting current type oxygen sensor, is made up of electrolyte layer 3, dense diffusion barrier layer 4, encapsulation layer 7, and positive collector 1, negative collector 5, is connected on positive collector 1 There is a positive lead 2 and a negative lead 6 is connected to the negative collector 5 . Among them, the electrolyte layer 3 and the dense diffusion barrier layer 4 are sintered toge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com